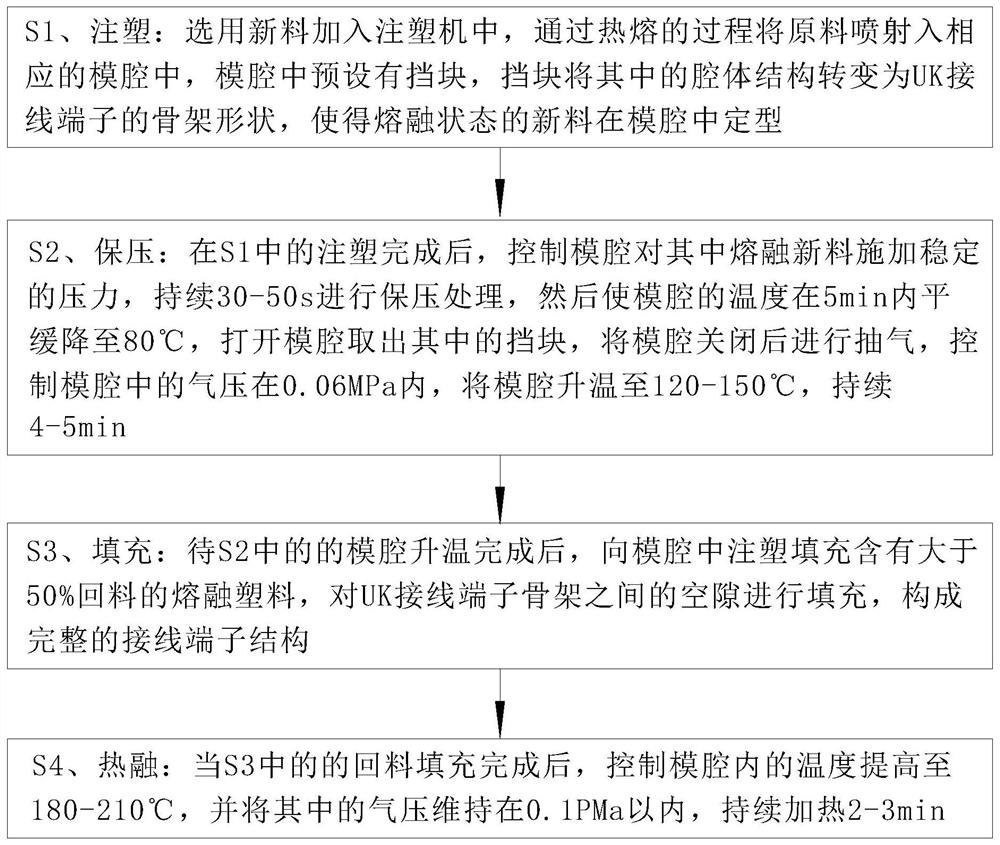

UK wiring terminal and manufacturing method thereof

A terminal, a pair of technology, applied in the contact box/base manufacturing, connection, conductive connection and other directions, can solve the problems of high injection molding cost, low cost, hidden safety hazards, etc., to maintain performance parameters, reduce production costs, The effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

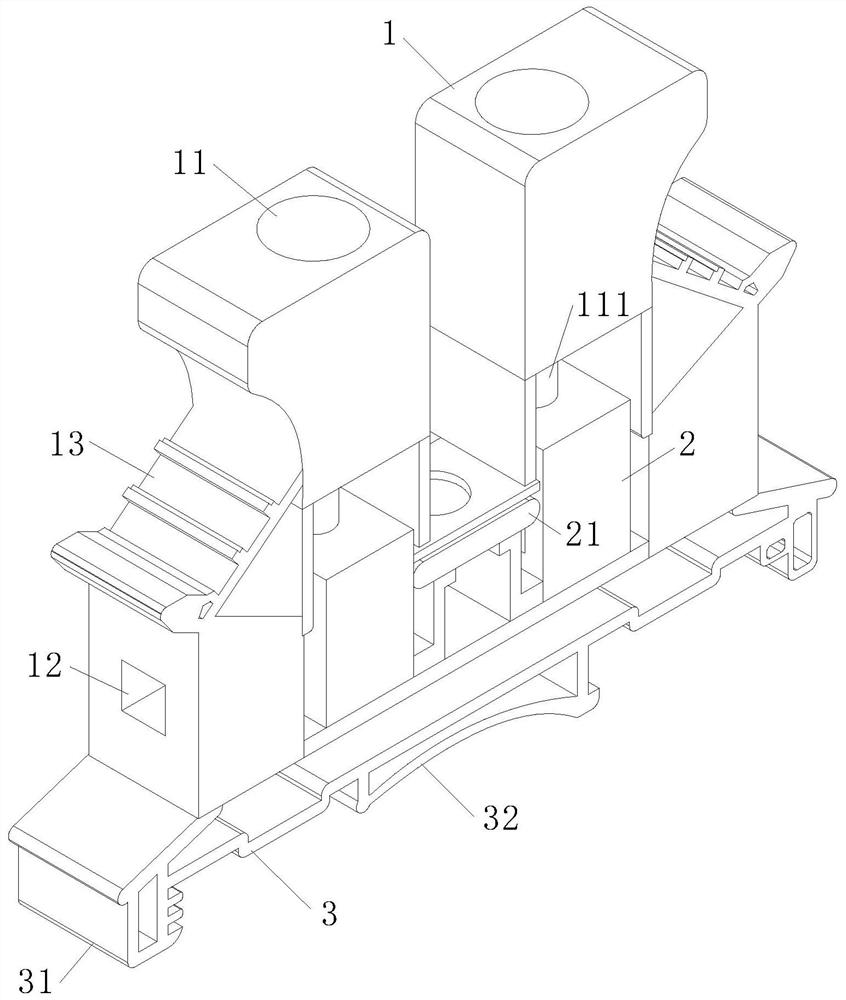

Examples

Embodiment approach

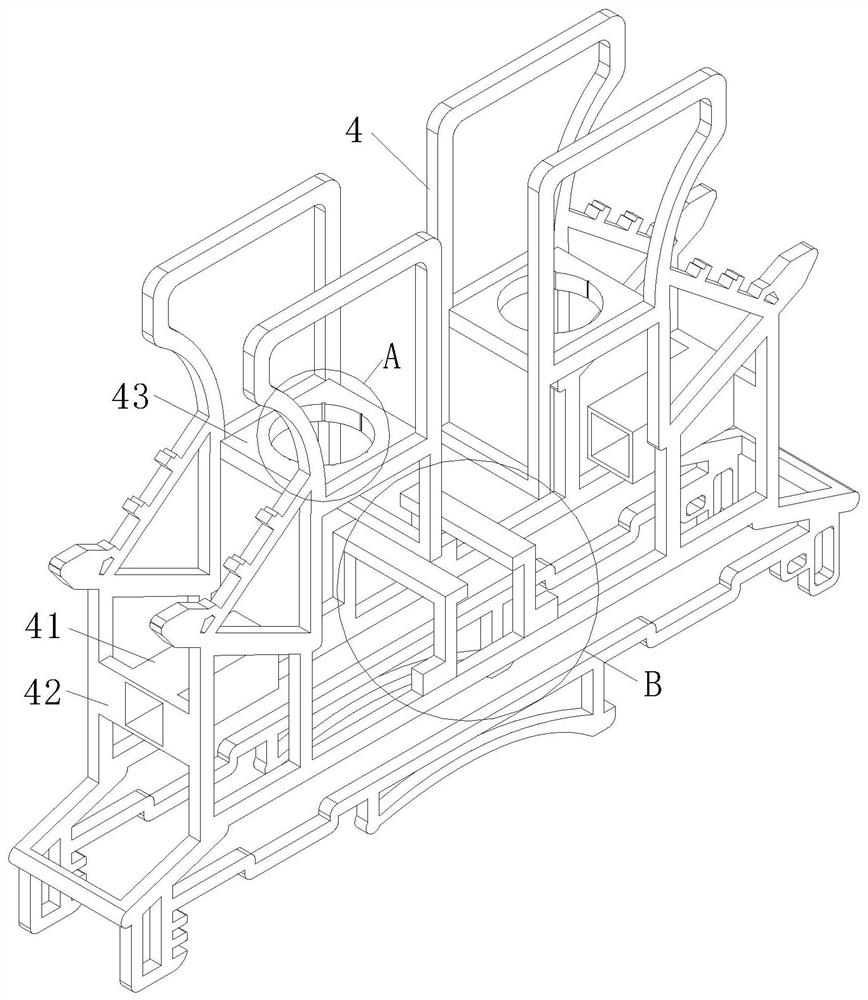

[0031] As an embodiment of the present invention, a pair of supporting blocks 22 are provided below the conductive sheet 21, and the cross section of the supporting blocks 22 is stepped; above the two supporting blocks 22, corresponding abutting plates 23 are provided; The conductive sheet 21 is installed between the supporting block 22 and the abutting plate 23; the conductive sheet 21 connects the two ends of the electric block 2, and the temperature change in the application environment and the current change in the circuit system make the conductive sheet 21 work for a long time. Deformation occurs after use, and the formed bending interferes with the transmission effect of the electrical signal, thereby reducing the quality of the UK terminal; through the brackets 22 and the abutment plates 23 arranged on the upper and lower sides of the conductive sheet 21, the brackets 22 are used The stepped shape interacts with the contact plate 23 to limit the deformation of the conta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com