Lithium-sulfur battery porous positive electrode and preparation method and application thereof

A lithium-sulfur battery and cathode technology, which is applied in the field of preparation of porous cathodes for lithium-sulfur batteries, can solve the problem that high sulfur loading, high electronic conductivity and high ionic conductivity cannot be synergistic, high sulfur loading, high electronic conductivity and high ionic conductivity can not be synergistic, to achieve the effect of improving cycle performance, high electronic conductivity, and high sulfur loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

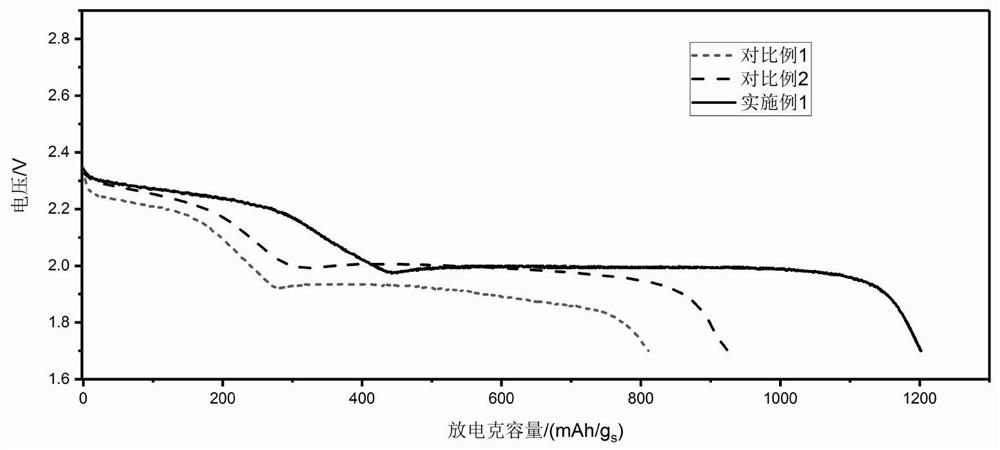

Image

Examples

Embodiment

[0054] The carbon material in the prepared porous positive plate is a mixture of porous carbon and conductive carbon black prepared by a silicon dioxide template method, the binder is polyvinylidene fluoride, and the molecular weight is between 900,000 and 1,000,000.

[0055] Table 1 The mass ratio percentage and electrochemical performance of each material of the positive electrode and its proportion

[0056]

[0057] The specific steps are:

[0058] Step (1): First positive ballasting of sulfur

[0059] The prepared porous carbon material was mixed with elemental sulfur, and cooled in an argon atmosphere, the pressure, and 160°C for 10 hours to obtain the first sulfur-loaded carbon material corresponding to the sulfur load in Table 1;

[0060] (2) The second positive ballast sulfur

[0061] (2-1) According to the ratio in Table 1, the first sulfur-loaded carbon material, nano-sulfur powder (pore-forming agent), and binder (polyvinylidene fluoride) are added to the dispe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com