Anti-impact protection device for vehicle transfer case

A protection device, transfer case technology, applied in the direction of transmission parts, transmission case, components with teeth, etc., can solve the problem of small safety clearance between the protective structure and the transfer case, affecting the performance and life of the transfer case, vehicle Scratch and collision accidents, etc., to achieve the effect of improving the force distribution of the structure, enhancing the overall stiffness, and enhancing the resistance to deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

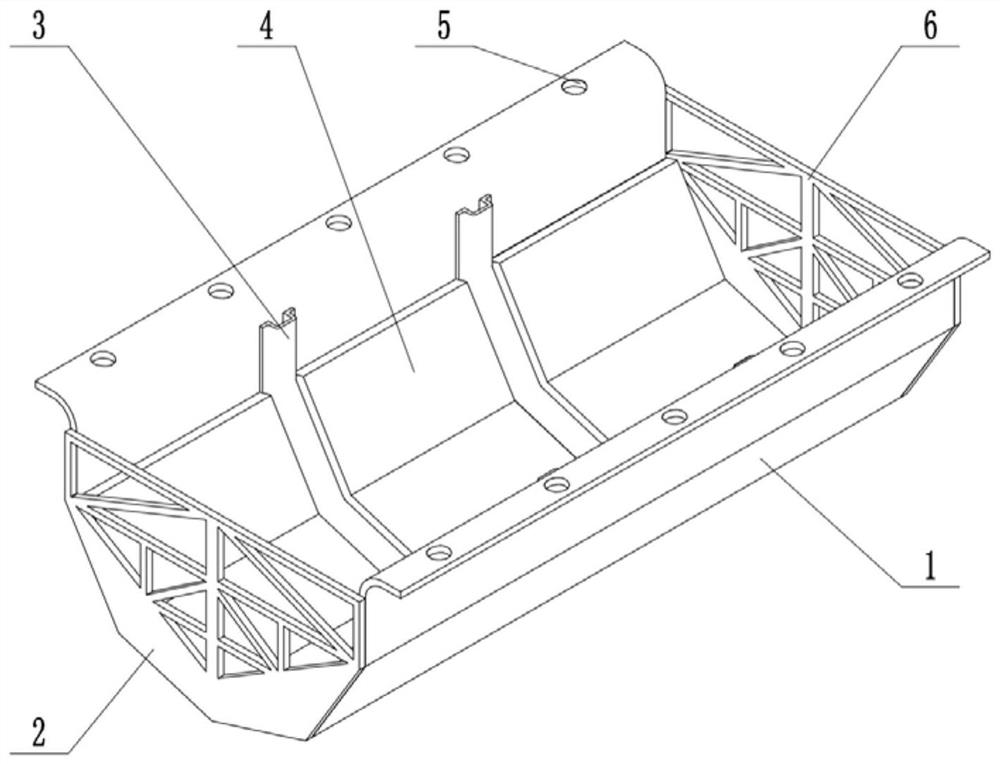

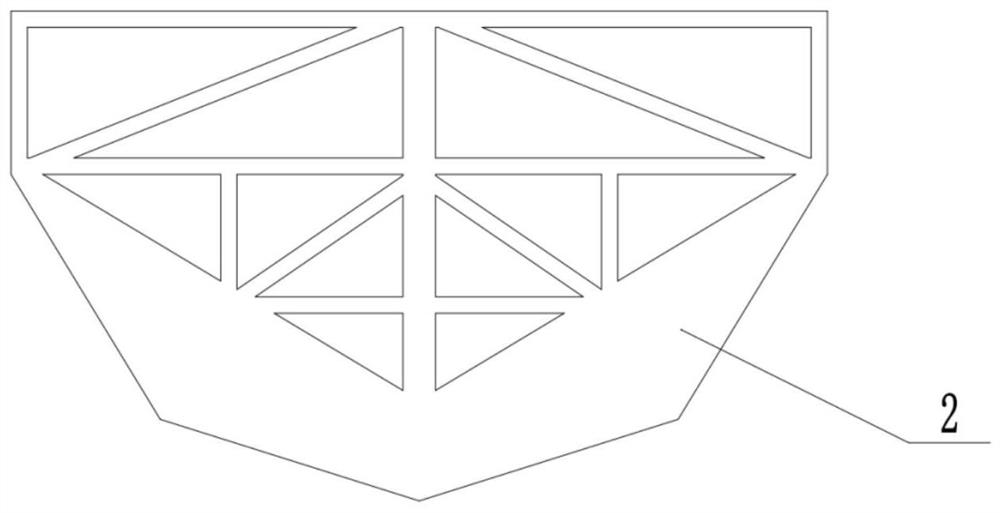

[0027] Such as Figure 1-3 As shown, a vehicle transfer case impact protection device includes double V-shaped bottom plate 1, front fender 2, U-shaped reinforcement beam 3, energy-absorbing buffer layer 4, bolt holes 5 and rear fender 6 six parts.

[0028] Wherein the front baffle 2, the rear baffle 6 and the U-shaped reinforcing beam 3 are fixedly connected with the double V-shaped bottom plate 1, and the connection methods are not limited to welding, bolt connection and the like. The energy-absorbing buffer layer 4 is arranged inside the double V-shaped bottom plate 1 and connected with the double V-shaped bottom plate 1 through an adhesive. The device is connected with the vehicle body through bolt holes 5 .

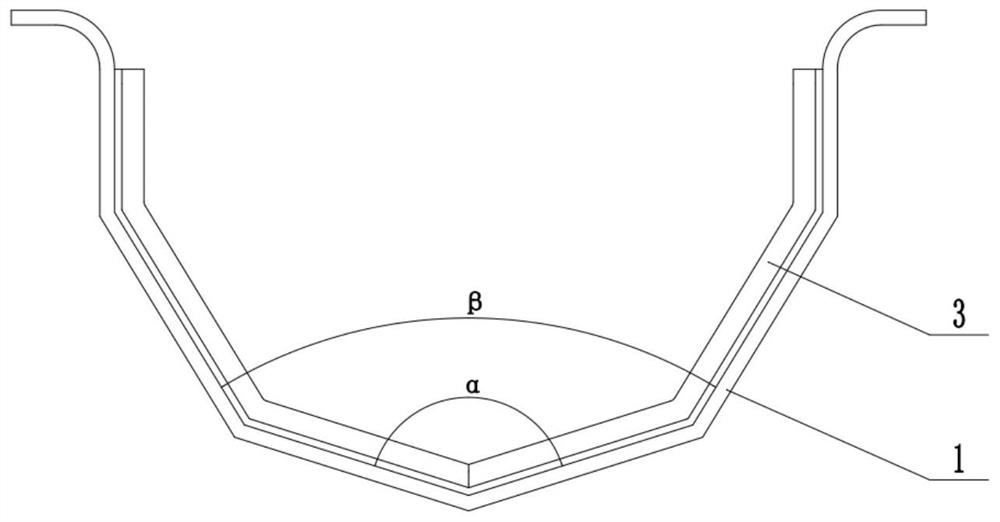

[0029] The double V-shaped bottom plate 1 contains two V-shaped included angles, which increase the overall rigidity of the structure and the int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com