Acidified oil rapid extraction device and process

An extraction device and acidified oil technology, which is applied in the field of rapid acidified oil extraction device, can solve the problems of obstacles to the promotion of biomass diesel industrialization and high cost, and achieve the effects of improving production efficiency, sufficient acidification, and improving heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

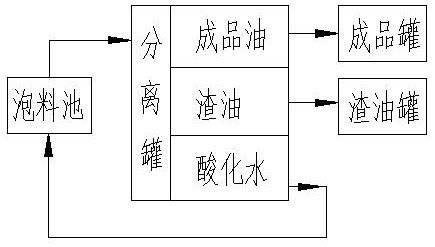

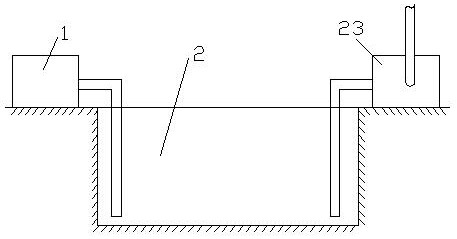

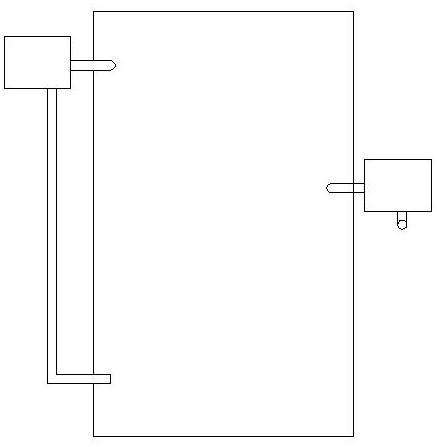

[0032] Such as figure 1 A rapid extraction device for acidified oil is shown, comprising a foam tank 2, a separation tank 3, a heating device for heating the liquid inside the separation tank, and a first circulating pump 1 arranged on the side of the bubble tank and the foam tank The liquid is sent to the transfer pump 23 in the separation tank.

[0033] The liquid inlet of the first circulation pump is connected with the first liquid inlet pipe extending below the liquid level of the foam material pool, and the lower end of the first liquid inlet pipe is close to the bottom of the foam material pool, and the liquid outlet of the first circulation pump is connected with The first liquid outlet pipe extending above the foam material pool, the first liquid inlet pipe and the first liquid outlet pipe are respectively close t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com