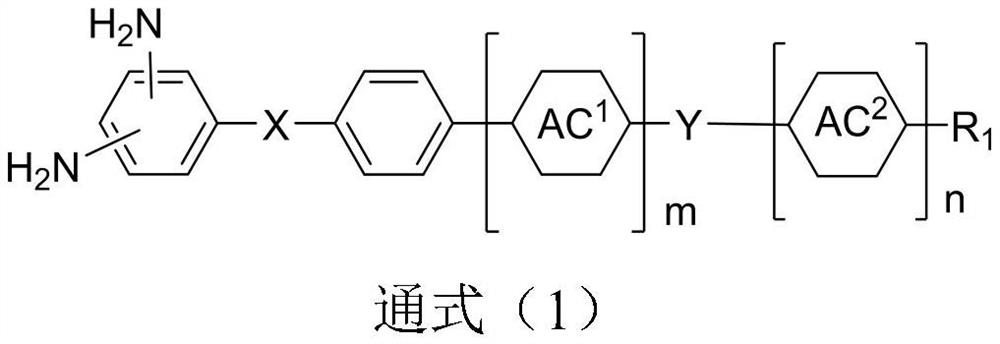

Liquid crystal alignment agent, liquid crystal alignment film, and liquid crystal display element

A technology of liquid crystal display elements and liquid crystal alignment agents, which is applied in the direction of liquid crystal materials, instruments, chemical instruments and methods, etc., can solve the problems of unstable placement of liquid crystal alignment agents, and achieve excellent thermal stability, small changes in pretilt angle, and changes in viscosity big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The compound (b-1-1) shown in formula I-1 can be synthesized according to the following synthetic route 1:

[0047]

[0048] Synthetic route 1

[0049] (1) Synthesis of compound b-1-1a

[0050] In a 1000mL three-neck round bottom flask, drop biphenol (37.2g, 200 mmol), 5CCMeO (53.2g, 200 mmol), PPh 3 (52.4g, 240 mmoles) and 500g THF were stirred at 25°C until they were fully dissolved, and DIAD (48.5g, 240 mmoles) was added dropwise for 0.5h, kept for 6 hours, desolvated to the remaining 210g, then cooled to -20°C, The solution was filtered, and the obtained solid was crystallized, filtered, and dried to obtain solid b-1-1a.

[0051] (2) Synthesis of compound b-1-1b

[0052] In a three-neck round bottom flask of 1000mL, drop 2,4-dinitrochlorobenzene (33.4g, 165 mmol), b-1-1a (65.2g, 150 mmol), potassium carbonate (27.6g, 200 mmol ) 500g of toluene, stirred and heated to reflux for 6 hours, then the temperature was lowered and the solution was filtered, the filtra...

Embodiment 2~4

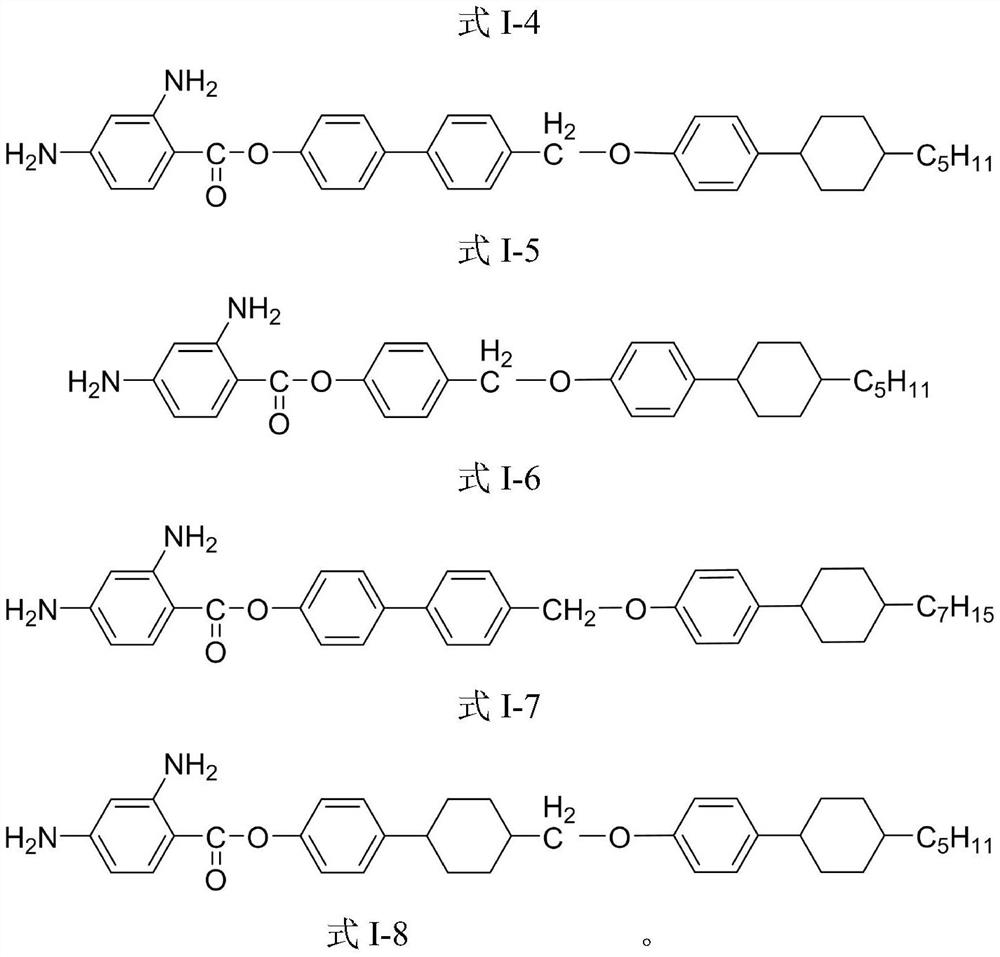

[0057] Compounds shown in formula I-2 (b-1-2), formula I-3 (b-1-3), formula I-4 (b-1-4) can be synthesized according to synthetic route 1 corresponding parent compound The phenol compound is then etherified with 2,4'-dinitrochlorobenzene to obtain the corresponding nitro compound; the nitro compounds of the structural formulas I-2 to I-4 are obtained, and then the nitro group is reduced by catalytic hydrogenation, The corresponding diamino compounds are obtained, and the high-resolution mass spectrometry data and elemental analysis results of the compounds represented by formulas I-2 to I-4 are shown in Table 1 below:

[0058] Table 1

[0059]

Embodiment 5

[0061] The compound shown in formula I-5 (b-1-5) can be synthesized according to the following synthetic route 2:

[0062]

[0063] Synthetic route 2

[0064] (1) Synthesis of compound (b-1-5a)

[0065] In a 1000mL three-necked round-bottomed flask, pentylcyclohexylphenol (49.2g, 200mmol), 4-hydroxybiphenylmethanol (40.1g, 200mmol), PPh 3 (52.4g, 240 mmoles) and 500g THF were stirred at 25°C until they were fully dissolved, and DIAD (48.5g, 240 mmoles) was added dropwise for 0.5h, kept for 6 hours, desolvated to the remaining 210g, then cooled to -20°C, The solution was filtered, and the obtained solid was crystallized, filtered, and dried to obtain solid b-1-5a.

[0066] (2) Synthesis of compound (b-1-5b)

[0067] Put b-1-5a (65.2g, 150mmol), potassium carbonate (27.6g, 200mmol) and 500g toluene into a 1000mL three-necked round-bottomed flask and stir to raise the temperature to 80°C. Slowly add 2 to the system, The mixed solution of 4-dinitrochlorobenzene (38.0g, 165 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com