Supporting strip material for cold shrink cable accessories and preparation method thereof

A technology for cable accessories and support strips, which is applied in the field of support strip materials for cold-shrinkable cable accessories and its preparation. It can solve the problems that support strips cannot be pulled out smoothly, silicone rubber products are not bonded, waste of materials and manpower, etc., and achieve light weight. , low density and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

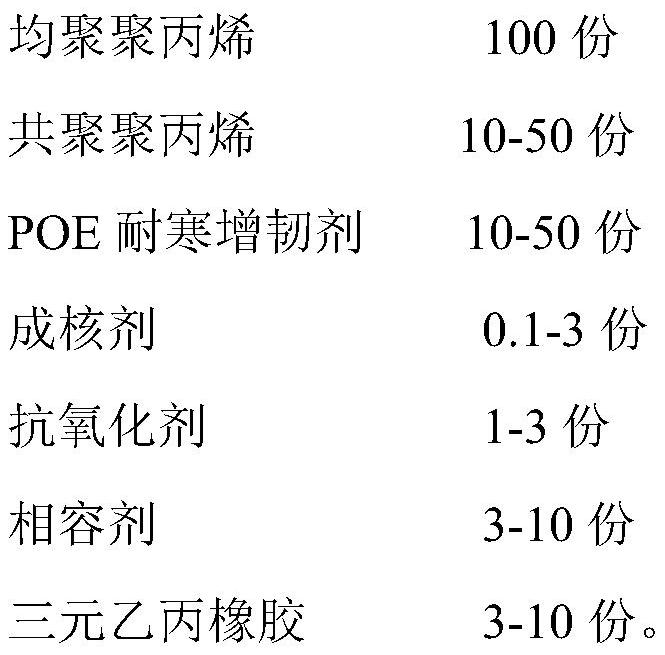

[0030] The support bar material for the cold-shrinkable cable accessories is made of the following raw materials in parts by mass:

[0031] 100 parts of homopolypropylene, 40 parts of copolymerized polypropylene, 30 parts of POE cold-resistant toughening agent, 1.5 parts of nucleating agent, 2.5 parts of antioxidant, 6 parts of compatibilizer, and 7 parts of EPDM.

[0032] The POE cold-resistant toughening agent is a high polymer of ethylene and butene using a metallocene catalyst.

[0033] The nucleating agent is an alpha crystal nucleating agent.

[0034] The antioxidant is hydroquinone.

[0035] The compatibilizer is a PP blend grafted with maleic anhydride, and the molecular weight is 4000-5000.

[0036] The preparation method of the support bar material for cold-shrinkable cable accessories includes the following steps:

[0037] Physically mix homopolypropylene, copolymerized polypropylene, POE cold-resistant toughening agent, nucleating agent, antioxidant, compatibili...

Embodiment 2

[0039] The support bar material for the cold-shrinkable cable accessories is made of the following raw materials in parts by mass:

[0040] 100 parts of homopolypropylene, 10 parts of copolymerized polypropylene, 10 parts of POE cold-resistant toughening agent, 3 parts of nucleating agent, 1 part of antioxidant, 10 parts of compatibilizer, and 10 parts of EPDM.

[0041] The POE cold-resistant toughening agent is a high polymer of ethylene and octene using a metallocene catalyst.

[0042] The nucleating agent is a β crystal nucleating agent.

[0043] The antioxidant is thiobisphenol.

[0044] The compatibilizer is a PP blend grafted with maleic anhydride, and the molecular weight is 4000-5000.

[0045] The preparation method of the support bar material for cold-shrinkable cable accessories includes the following steps:

[0046] Physically mix homopolypropylene, copolymerized polypropylene, POE cold-resistant toughening agent, nucleating agent, antioxidant, compatibilizer and...

Embodiment 3

[0048] The support bar material for the cold-shrinkable cable accessories is made of the following raw materials in parts by mass:

[0049] 100 parts of homopolypropylene, 50 parts of copolymerized polypropylene, 50 parts of POE cold-resistant toughening agent, 1 part of nucleating agent, 3 parts of antioxidant, 8 parts of compatibilizer, and 3 parts of EPDM.

[0050] The POE cold-resistant toughening agent is a high polymer of ethylene and octene using a metallocene catalyst.

[0051] The nucleating agent is a mixture of an α crystal nucleating agent and a β crystal nucleating agent, and the mixing ratio is 1:1.

[0052] The antioxidant is p-phenylenediamine.

[0053] The compatibilizer is a PP blend grafted with maleic anhydride, and the molecular weight is 4000-5000.

[0054] The preparation method of the support bar material for cold-shrinkable cable accessories includes the following steps:

[0055] Physically mix homopolypropylene, copolymerized polypropylene, POE col...

PUM

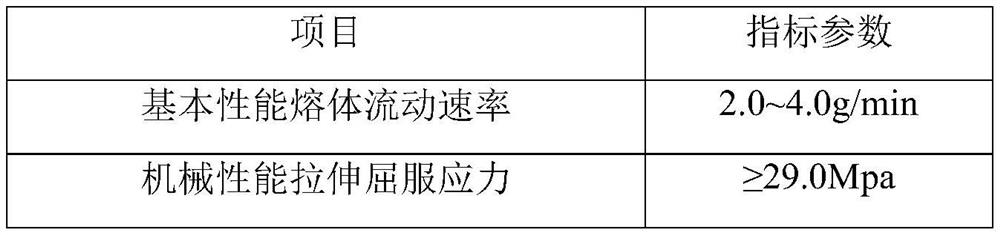

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com