High-hydrophilicity nanofiber coating-based nanofiltration membrane and preparation method thereof

A nanofiber and hydrophilic technology, which is applied in the field of nanofiltration membranes, can solve the problem that composite nanofiltration membranes are difficult to achieve the effect of large flux and high rejection rate at the same time, and it is difficult to overcome the trade-off between separation flux and separation selectivity. , nanofiltration membrane separation flux increase limited and other issues, to achieve the effect of synergistic increase in flux and rejection rate, excellent hydrophilicity, and small thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The invention provides a method for preparing a highly hydrophilic nanofiber coating-based nanofiltration membrane: comprising the following steps:

[0036] S1, dispersing ethylene-vinyl alcohol copolymer nanofibers with a diameter of 0.05-0.5 μm in a solvent, stirring evenly to prepare a dispersion liquid with a solid content of 0.2-6.0 wt% of the ethylene-vinyl alcohol copolymer nanofibers, sealing save;

[0037] S2, using the spraying method to apply the dispersion liquid prepared in step S1 on one surface of the micron fiber non-woven fabric base layer, the coating thickness is 2-10 μm, and the coating density is 5-10 g / m 2 , dried to prepare the nanofiber coating base film;

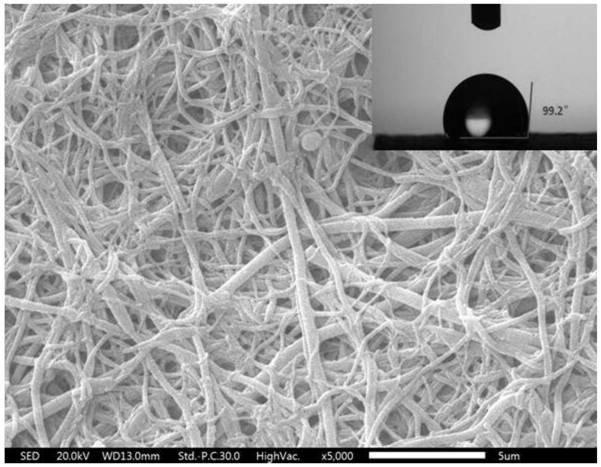

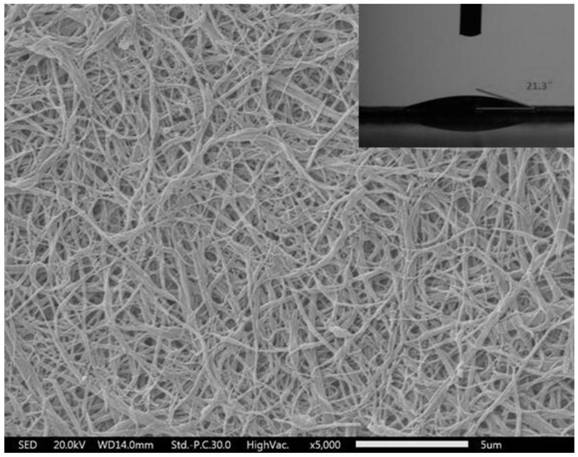

[0038] S3, soak the nanofiber coating base film prepared in step S2 in an alkali solution of predetermined concentration for 15-60min, wash and air-dry, and then conduct plasma treatment in air or sulfur dioxide atmosphere for 1-5min, to obtain a surface containing Highly hydrophilic nanofib...

Embodiment 1

[0046] A preparation method of a highly hydrophilic nanofiber coating-based nanofiltration membrane, comprising the following steps:

[0047] S1, disperse ethylene-vinyl alcohol copolymer nanofibers with a diameter of 0.05-0.5 μm in a mixed liquid phase with a mass ratio of ethanol and deionized water of 1:1, and stir to prepare nanofibers with a solid content of 0.5 Wt% dispersion liquid, sealed and stored;

[0048] S2, the nanofiber dispersion is coated on one surface of the polyamide non-woven substrate by spraying, the coating thickness is 5 μm, and the coating density is 6 g / m 2 , dried in vacuum at room temperature to prepare a nanofiber coating base film;

[0049] S3, prepare a NaOH alkali solution with a concentration of 3mol / L, soak the nanofiber coating base film in the NaOH alkali solution for 15min, then wash it with water and ethanol for several times, and perform plasma treatment in the air atmosphere after air-drying 5min, sealed and stored to obtain a highly ...

Embodiment 2-5

[0057] The difference from Example 1 is: in the interfacial polymerization process of step S4, the concentration of water phase monomer and oil phase monomer, i.e. piperazine (PIP), triethylamine (TEA) and trimesoyl chloride (TMC) The settings are different, and the specific settings are as shown in Table 1, and the others are the same as in Embodiment 1, and will not be repeated here.

[0058] Table 1 is embodiment 1-5 and process parameter setting and performance parameter

[0059]

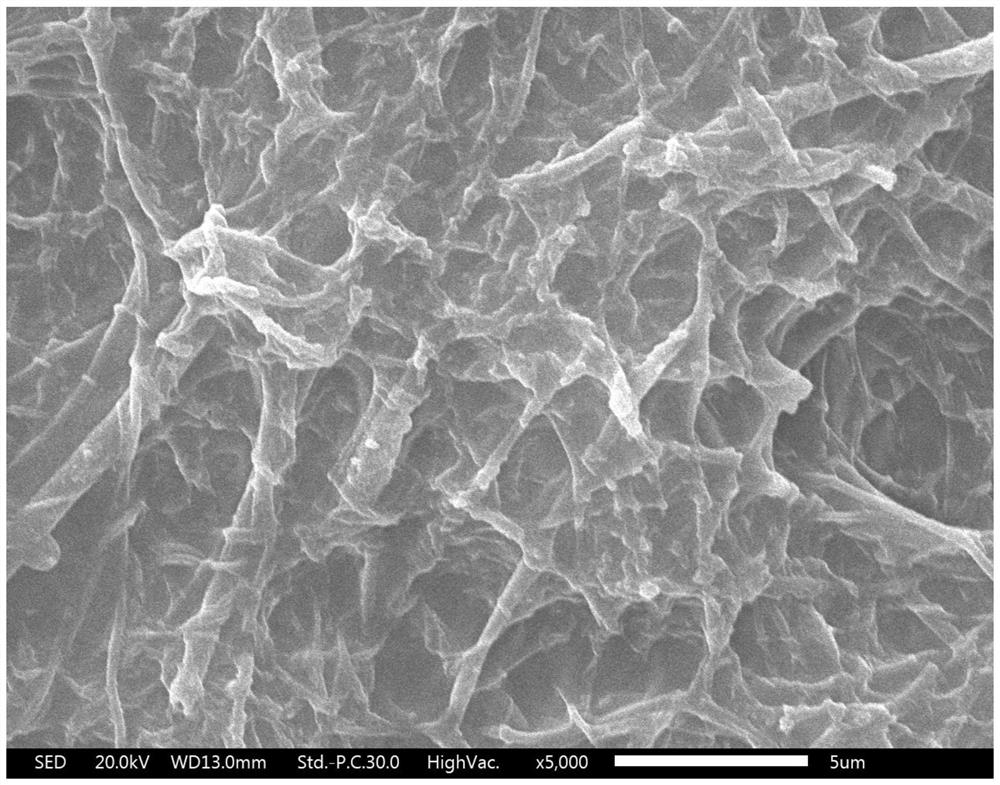

[0060] The interfacial polymerization process is controlled by diffusion. The structure and chemical properties of different monomers lead to differences in solubility and diffusion rates in the two phases, and finally form selective separation layers with different crosslinking degrees, pore sizes, and hydrophilic and hydrophobic properties. The selection of suitable interfacial polymerization monomers plays a decisive role in the construction of high permeation selectivity composite nanofil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com