Double-layer silicon dioxide coated granule and preparation method and application thereof

A technology of silica and particles, which is applied in the field of double-layer silica-coated particles and its preparation, can solve the problems of destroying the color and taste of toothpaste, being easily oxidized, and the color of natural antibacterial agents is heavy, so as to avoid being easily oxidized, Improve stability and wrap stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

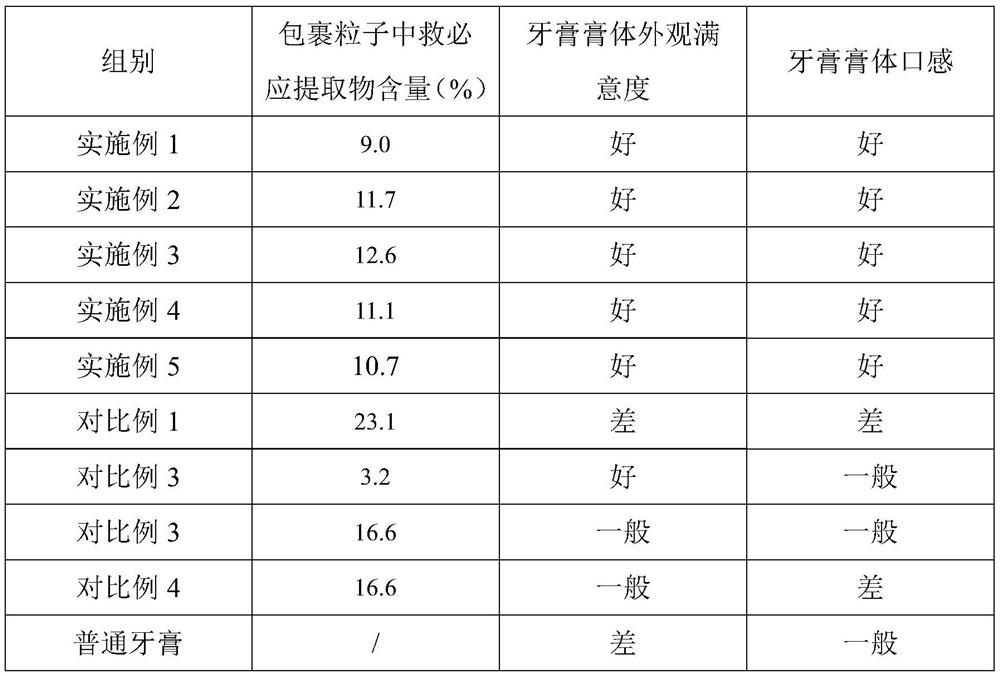

Examples

Embodiment 1

[0030] Embodiment 1, a kind of double-layer silica coated particle

[0031] The preparation method of the double-layer silica-coated particles comprises the following steps:

[0032] S1, the preparation mass percentage is the ethyl cellulose solution of 3%;

[0033] S2. Add 2kg of silicon dioxide powder and 0.2kg of jiubing extract to the mixer, the mixing weight ratio of silicon dioxide powder and jiubing extract is 10:1, and the average particle size of silicon dioxide is 9 μm. The particle size of the Bing extract is 10 μm, and the premix is prepared by stirring for 10 minutes at a rotation speed of 400 rpm;

[0034] S3. Put the premix prepared in step S2 into the fluidized granulation dryer, set the fan frequency to 25Hz, the inlet air temperature to 60°C, and the outlet air temperature to 40°C, start the program, and start the atomization after the fan runs for 5 minutes device, spray ethyl cellulose solution, the injection speed of ethyl cellulose solution is 0.5m 3...

Embodiment 2

[0037] Example 2, a double-layer silica-coated particle

[0038] The preparation method of the double-layer silica-coated particles comprises the following steps:

[0039] S1, the preparation mass percentage is the ethyl cellulose solution of 3.5%;

[0040] S2. Add 3kg of silicon dioxide powder and 0.4kg of jiubing extract to the mixer, the mixing weight ratio of silicon dioxide powder and jiubing extract is 10:1.3, and the average particle size of silicon dioxide is 13 μm. The particle size of the Bing extract is 20 μm, and the premix is prepared by stirring for 10 minutes at a rotation speed of 400 rpm;

[0041] S3. Add the premix prepared in step S2 into the fluidized granulation dryer, set the fan frequency to 28Hz, the inlet air temperature to 65°C, and the outlet air temperature to 43°C, start the program, and start the atomization after the fan runs for 5 minutes device, spray ethyl cellulose solution, the injection speed of ethyl cellulose solution is 0.6m 3 / h, o...

Embodiment 3

[0044] Embodiment 3, a kind of double-layer silica coated particle

[0045] The preparation method of the double-layer silica-coated particles comprises the following steps:

[0046] S1, the preparation mass percentage is the ethyl cellulose solution of 4%;

[0047] S2. Add 3kg of silicon dioxide powder and 0.45kg of jiubing extract to the mixer, the mixing weight ratio of silicon dioxide powder and jiubing extract is 10:1.5, and the average particle size of silicon dioxide is 15 μm. The particle size of the Bing extract is 35 μm, and the premix is prepared by stirring for 10 minutes at a rotation speed of 400 rpm;

[0048] S3. Put the premix prepared in step S2 into the fluidized granulation dryer, set the fan frequency to 30Hz, the inlet air temperature to 70°C, and the outlet air temperature to 45°C, start the program, and start the atomization after the fan runs for 5 minutes device, spray ethyl cellulose solution, the injection speed of ethyl cellulose solution is 0.7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com