Method and device for storing and preserving edible mushrooms

A technology for storage and preservation of edible fungi, applied in the field of edible fungi preservation, can solve the problems of violation of food safety requirements, short shelf life, restricting the development of edible fungi industry, etc., and achieve the effect of saving labor and water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: a kind of preservation method of edible mushroom, comprises the following steps:

[0028] Take shiitake mushrooms as an example:

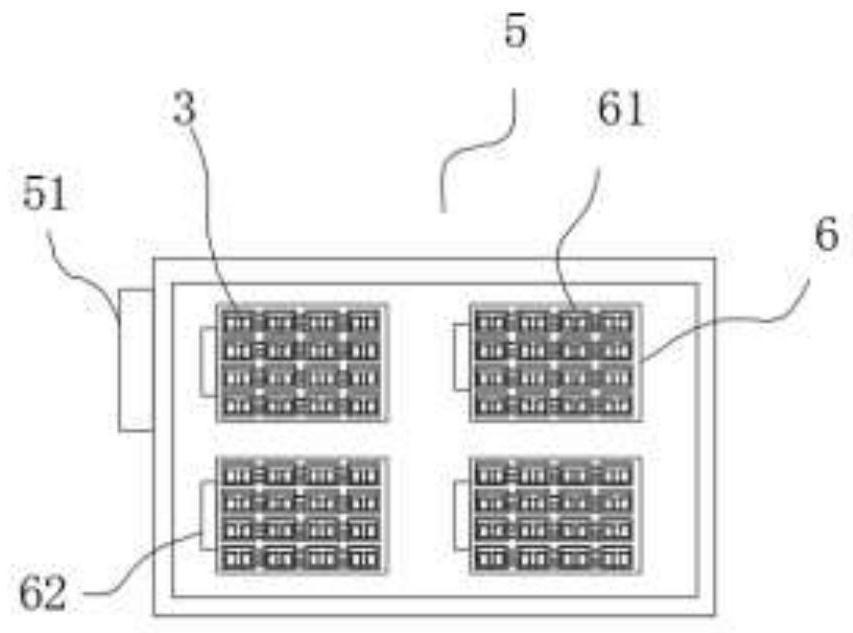

[0029] Step 1 Material selection: select high-quality shiitake mushrooms that are complete, odorless, and pest-free as raw materials, and classify shiitake mushrooms with different cap diameters. More than 5cm is one category, and the three types of edible fungi are respectively placed in the placement boards 3 of different sizes;

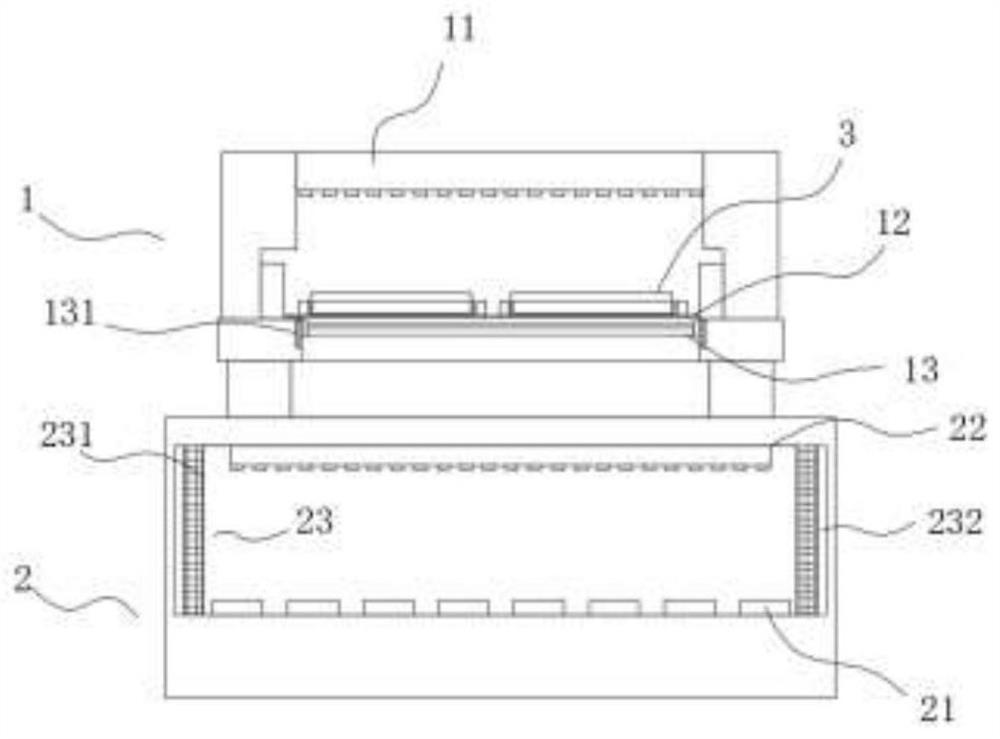

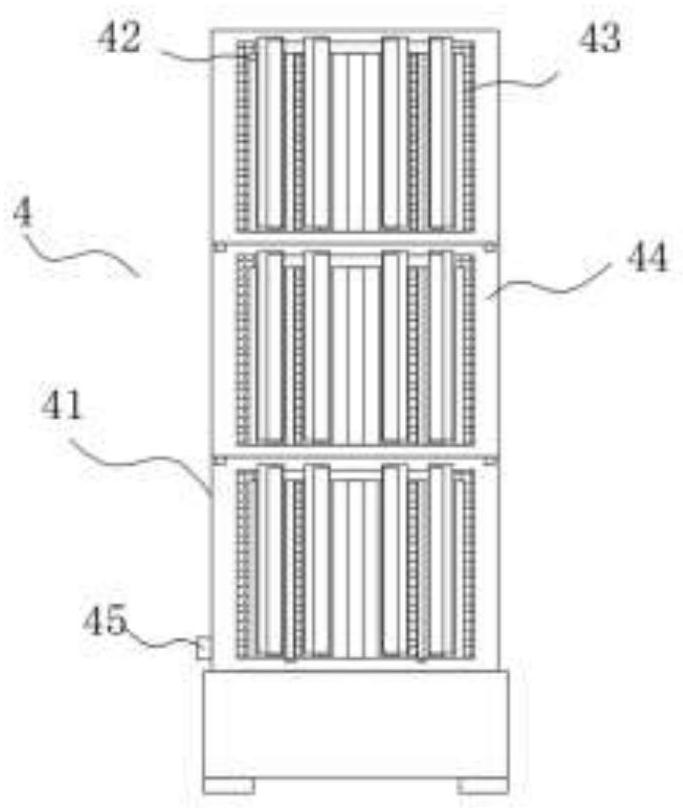

[0030] Step 2 Pretreatment: place the plate 3 with the shiitake mushrooms on the transmission mechanism, process the soil on the surface of the mushroom caps through the pretreatment mechanism 1, and cool and clean the surface of the shiitake mushrooms, so that the surface temperature of the shiitake mushroom caps drops to 3 ℃, and cut the stipe, leaving a stipe length of 3cm;

[0031] Step 3 Mushroom cleaning: transport the plate 3 filled with cut mushrooms into the cleaning mechanism 2 for soaki...

Embodiment 2

[0038] Embodiment 2: a kind of preservation method of edible mushroom, comprises the following steps:

[0039] Take Agaricus bisporus as an example:

[0040] Step 1 material selection: select high-quality Agaricus bisporus that is complete, odorless, and pest-free as raw materials, and classify Agaricus bisporus with different cap diameters. The Agaricus bisporus with a cap diameter between 0.3-1 cm is sorted out and placed in the placement plate 3;

[0041]Step 2 Pretreatment: Place the plate 3 on which the Agaricus bisporus is placed on the conveying mechanism, process the soil on the surface of the Agaricus bisporus cap through the pretreatment mechanism 1, and cool and clean the surface of the Agaricus bisporus cap to reduce the surface temperature of the Agaricus bisporus cap to 5 ℃, and cut the stipe, the length of the cut stipe is within 1cm;

[0042] Step 3 Cleaning of Agaricus bisporus: transport the plate 3 filled with cut mushrooms into the cleaning mechanism 2 for...

Embodiment 3

[0048] Embodiment 3: a kind of preservation method of edible mushroom, comprises the following steps:

[0049] Take oyster mushrooms as an example:

[0050] Step 1 material selection: select high-quality oyster mushrooms that are complete, odorless, and pest-free as raw materials, classify oyster mushrooms in different clusters, and place oyster mushroom clusters exceeding 5 cm in the placement plate 3;

[0051] Step 2 pretreatment: Place the plate 3 on which the flat mushrooms have been placed on the transmission mechanism, process the soil on the surface of the flat mushroom caps through the pretreatment mechanism 1, and cool and clean the surface of the flat mushrooms to make the surface of the flat mushroom caps The temperature drops to 3°C, and the stipe is cut, and the length of the cut stipe is within 1cm;

[0052] Step 3 Pleurotus ostreatus cleaning: Transport the plate 3 filled with cut oyster mushrooms into the cleaning mechanism 2 for soaking for 5 minutes, and mak...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com