Fully automatic shoe sole paint spraying machine

A paint spraying machine, fully automatic technology, applied in the field of paint spraying machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be further described below with reference to the accompanying drawings:

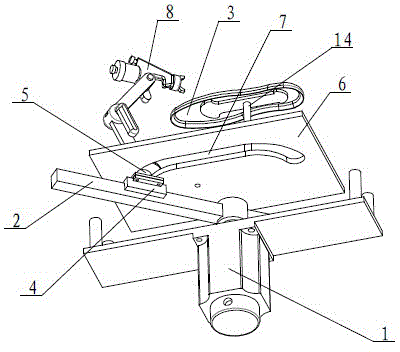

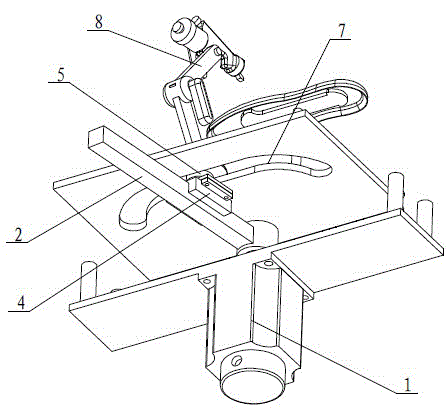

[0023] As shown in the figure, a fully automatic shoe sole painting machine includes a spray gun 8, and also includes a transmission mechanism that drives the movement of the spray gun to spray the shoe sole workpiece. The transmission mechanism includes a power source 1, a linear guide rail 2, and a slider 4 , the moving part 5 and the guide plate 6, the linear guide rail 2 includes a connecting end 21 and a slide rail portion 22, the linear guide rail 2 takes the connecting end 21 as the center of rotation, and the power source 1 drives the linear guide rail 2 through the connecting end 21 The guide rail 2 rotates around the center of rotation, the slide rail part 22 has a certain sliding length, the slide member 4 is slidingly matched with the slide rail part 22, the guide rail groove 7 is provided on the guide plate 6, and the spray gun 8 is fixedly co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com