Preparation method of vanadium compound electrode material and application of vanadium compound electrode material in aqueous zinc ion battery

A zinc-ion battery and electrode material technology, applied in the field of electrochemical materials, can solve problems such as insufficient loading capacity and insufficient battery performance, and achieve the effects of increasing the loading capacity per unit area, improving electrochemical performance, and avoiding peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] A preparation method of a vanadium compound electrode material and its application in an aqueous zinc-ion battery, comprising the following steps:

[0025] S1. Preparation of active materials: Dissolve the vanadium compound with solvent water, seal the mixed solution in an autoclave, and then keep it at 100-200°C for 2-120 hours, after cooling to room temperature, wash the product with deionized water Once, after drying (freeze drying, blast drying and natural drying, etc.), the desired vanadium compound active material is obtained.

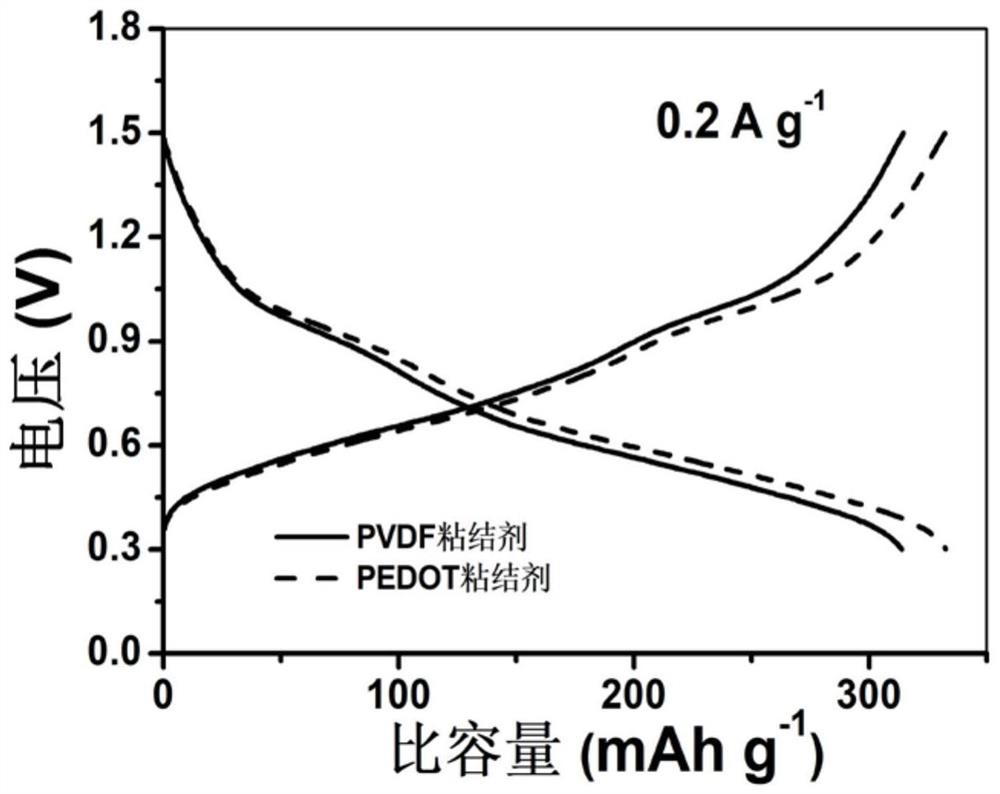

[0026] S2. Preparation of high-loaded vanadium-based compound electrode sheets: the obtained vanadium-based compound, conductive carbon and conductive binder are used in a specific weight ratio (6:3:1 or 7:2:1 or 8:1:1) Mix to form a uniform slurry, immerse the three-dimensional current collector in the slurry, then take it out to dry, repeat the above immersion and drying process several times, until the vanadium compound electrode sheet ...

Embodiment 1

[0030] Preparation of vanadium dioxide active material: Take vanadium pentoxide solid and add it to distilled water, add a certain amount of oxalic acid, stir in a water bath at 80°C for 1 hour, the mixed solution will turn into a dark blue solution, and then seal the mixed solution in an autoclave , and then kept at 180°C for 4 hours. After cooling to room temperature, the product was washed several times with deionized water to obtain vanadium dioxide nanorods.

[0031] Preparation of vanadium dioxide positive electrode on three-dimensional current collector: 3 mg·mL -1 The vanadium dioxide was mixed with conductive carbon and conductive binder in a weight ratio of 7:2:1 to form a homogeneous slurry. Immerse a piece of carbon felt with a diameter of 10mm as a three-dimensional current collector into the slurry, then take it out to dry, repeat this process 10-30 times, and obtain a mass load of 3-15mg / cm 2 electrode pads.

[0032] Assembly of water-based zinc-ion battery: ...

Embodiment 2

[0034] Preparation of vanadium pentoxide active material: Add solid ammonium vanadate to distilled water, add a certain amount of hydrochloric acid, the mixed solution will turn into a brown solution, then seal the mixed solution in an autoclave, and then keep it at 120°C for 24 hours. After cooling to room temperature, the product was washed several times with deionized water to obtain vanadium pentoxide material.

[0035] Preparation of vanadium pentoxide cathode on a three-dimensional current collector: 3 mg·mL -1 The vanadium pentoxide was mixed with conductive carbon and conductive binder in a weight ratio of 7:2:1 to form a homogeneous slurry. A piece of carbon felt with a diameter of 10 mm was immersed in the slurry as a three-dimensional current collector, and then taken out to dry. This process was repeated 10-30 times until an electrode sheet with the desired mass load was obtained.

[0036] Assembly of water-based zinc-ion battery: The prepared electrode sheet, fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com