Solar spectrum absorption film layer design method

A solar spectrum and design method technology, applied in the field of solar spectrum absorption film layer design, can solve the design and optimization of few processes, and achieve the goal of perfecting the design and process optimization methods, reducing the selection range, and reducing the loss of human labor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

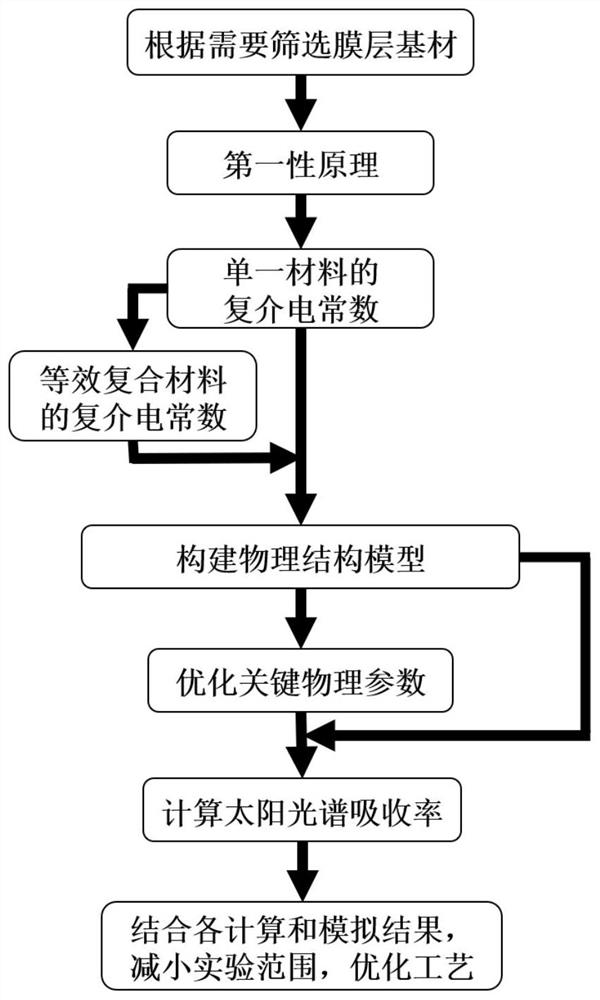

[0041] Such as figure 1 Shown, the present invention provides a kind of solar spectrum absorbing film layer design method, comprises the following steps:

[0042] Step 1: Determine the dielectric function of the preselected material;

[0043] The step 1 is specifically:

[0044] Step 1.1: Select the type of material to be used based on the environmental stability, hardness and toughness of the pre-selected material, construct the unit cell model of the selected material in the Materials Studio crystal library, export it as a CIF file, and open it with an editor to extract the required VASP POSCAR information, and converted to POSCAR file;

[0045] Step 1.2: According to the elemental composition and unit cell model of the material, extract the PBE-GGA pseudopotential of the elements contained in the material, construct the POSCAR file, and obtain the KPOINTS file and the INCAR file;

[0046] Step 1.3: Create a scf folder, convert the CONTCAR file obtained by structural opti...

specific Embodiment 2

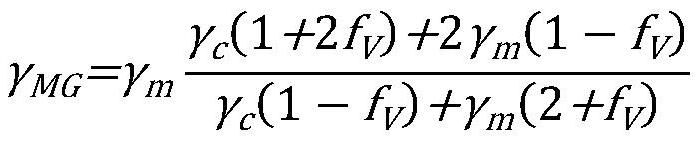

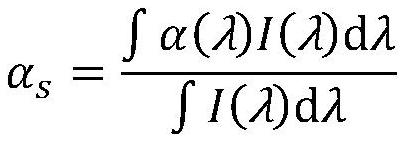

[0071] Step 1: Calculate the dielectric function of the pre-selected material by the first-principle method. Under the ideal surface state of the ideal bulk material, using the Fresnel formula, the spectral reflectance ρ and its refraction of the material at the corresponding wavelength λ can be obtained The relationship between the rate n and the extinction coefficient k:

[0072]

[0073] In the range of the solar spectrum, it is considered that the thickness of the film layer must be greater than its skin depth. In the absence of transmission, the following formula is satisfied at this time:

[0074]

[0075] It can be seen that the light absorption rate of the surface of an ideal bulk material is determined by the refractive index and extinction coefficient of the material, and the refractive index and extinction coefficient are actually related to the dielectric function:

[0076]

[0077]

[0078] Further, according to the Kramers-Kronig dispersion relation a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com