Rapid quantitative fluorescence detection device for 3-deoxyfructose and preparation method thereof

A deoxyfructose, quantitative detection technology, applied in measurement devices, biological tests, material inspection products, etc., can solve the problem that the concentration of 3-deoxyfructose cannot be detected, the fluorescence is easily quenched, and the NC membrane has insufficient protein adsorption and weak binding force. and other problems, to achieve the effect of improving reasonable comprehensive judgment, increasing complexity and strong specificity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

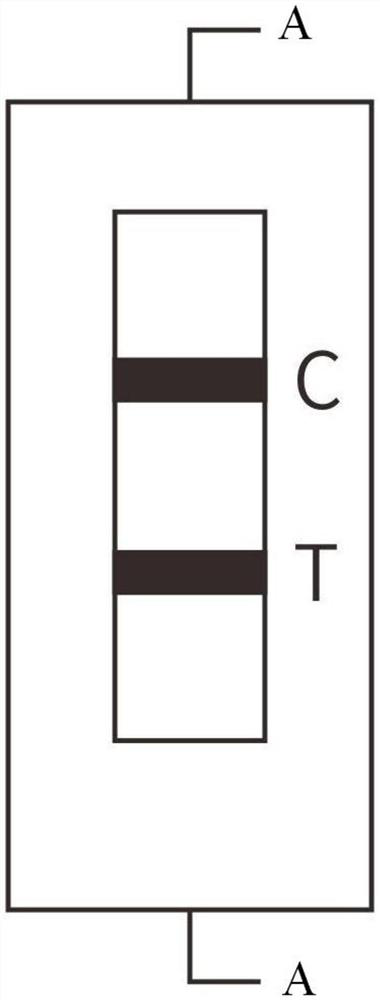

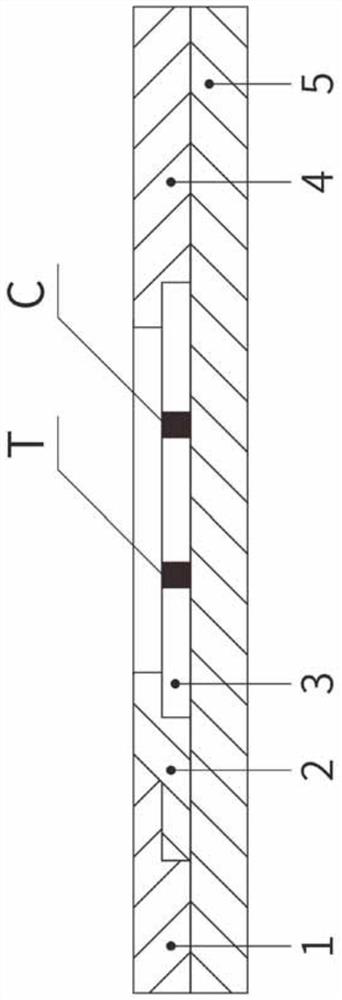

[0037] The sample pad 1, the immunofluorescent antibody glass fiber membrane 2, the immunonitrocellulose membrane 3, and the absorbent pad 4 are respectively pasted on the plastic plate 5, and the two ends of the immunonitrocellulose membrane 3 are respectively connected to the absorbent pad 4, the immunofluorescent antibody glass The fiber membrane 2 is overlapped, and the other end of the immunofluorescence antibody glass fiber membrane 2 is overlapped with the sample pad 1; a detection line T and a quality control line C are set on the immunonitrocellulose membrane 3, and the detection line T The upper solid phase has 3 deoxyfructose-carrier protein; or the first detection line T line solid phase 3 deoxyfructose-carrier protein, and the quality control line C is sprayed with goat anti-rabbit IgG polyclonal antibody; There are 3 deoxyfructose-carrier proteins on the solid phase of the detection line T, and the 3-deoxyfructose-carrier proteins refer to: ovalbumin OVA, or bovin...

Embodiment 2

[0057] Preparation of polyethylene glycol glycerin treatment solution: mixed with polyethylene glycol glycerin and polylysine (SIGMA, 150KD), wherein the concentration of polyethylene glycol glycerin is 0.5%, and polylysine The concentration is 0.5%, filtered through a 0.22μm filter membrane, and set aside;

[0058] Sample pad pretreatment

[0059]Soak the glass fiber in the sample pad treatment solution for 10 minutes, the sample pad treatment solution includes: Tris-HCL solution concentration 0.1M, bovine serum albumin BSA concentration 0.7%, casein concentration 0.15%, surfactant alkyl The concentration of phenol polyoxyethylene ether is 0.7%, and it is dried at 37°C for later use. After the treatment, the sample pad can improve the reaction sensitivity;

[0060] All the other are with embodiment 1.

Embodiment 3

[0062] Preparation of polyethylene glycol glycerin treatment solution: mixed with polyethylene glycol glycerin, polylysine (SIGMA, 150KD) and PEG2000, wherein the concentration of polyethylene glycol glycerin is 0.5%, poly The concentration of lysine is 0.5%, the concentration of PEG20000 is 0.1%, and it is filtered through a 0.22 μm filter membrane, and it is set aside;

[0063] Sample pad pretreatment

[0064] Soak the glass fiber in the sample pad treatment solution for 10 minutes, the sample pad treatment solution includes: Tris-HCL solution concentration of 0.1M, bovine serum albumin BSA concentration of 1%, casein concentration of 0.2%, surfactant alkyl The concentration of phenol polyoxyethylene ether is 1%, and it is dried at 37°C for later use. After the treatment, the sample pad can improve the reaction sensitivity;

[0065] All the other are with embodiment 1.

[0066] Further illustrate the effect of the present invention by experiment below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com