Tube push bench and recyclable construction method of main machine of tube push bench

A construction method and pipe jacking machine technology, applied in earthwork drilling, wellbore lining, tunnel lining, etc., can solve the problems of inability to integrate the shield construction of the sunken pump room and difficult recovery of the main engine, so as to achieve less personnel and reliable construction. The effect of controlling and preventing gushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

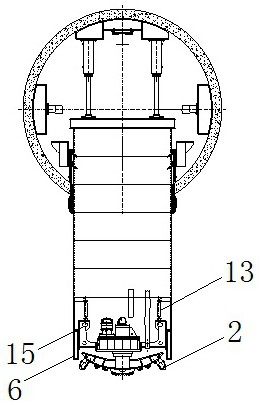

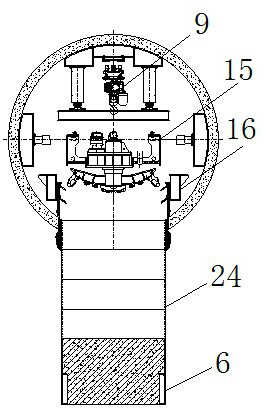

[0053] Embodiment 1, a kind of pipe jacking machine, such as figure 1 with figure 2 As shown, the shield body 6 is included, and the cutter head system driven by the host is arranged in the shield body 6 . The main engine includes a motor 5 or a hydraulic motor, which drives a main shaft 3 through a reducer 4, and the front end of the main shaft 3 is connected with a conical cutterhead 1, and a hob 19 and a side scraper 2 are arranged on the conical cutterhead 1.

[0054] A platform 21 is provided on the outside of the shield body 6 , and a pushing system cooperating with the shield body 6 is provided on the top of the platform 21 . Under the action of the rotary drive of the main engine and the vertical thrust of the jacking system, the conical cutter head 1 rotates downward to excavate the soil.

[0055] A shield inner sleeve 15 is detachably connected to the shield body 6 , the main engine is fixedly arranged in the shield inner sleeve 15 , and the front end of the shiel...

Embodiment 2

[0060] Embodiment 2, a pipe jacking machine, the shield body 6 is connected to the upper end of the inner sleeve 15 of the shield through a connecting baffle plate 14 with bolts. The connecting baffle 14 can transmit the thrust from the vertical shoe 22 to the main engine; at the same time, after the downward construction is completed, the connecting baffle 14 is removed, and the shield body 6 and the inner sleeve 15 of the shield are separated, and the pipe jacking machine can be realized. Host recycling.

[0061] Other structures of this embodiment are the same as those of Embodiment 1.

Embodiment 3

[0062] Embodiment 3, a pipe jacking machine, a recovery oil cylinder 13 is arranged between the shield body 6 and the inner sleeve 15 of the shield, when the connecting baffle 14 is removed and the shield body 6 and the inner sleeve 15 of the shield are separated, The recovery oil cylinder 13 can conveniently realize the separation of the shield body 6 and the sleeve 15 in the shield body.

[0063] Further, one end of the recovery oil cylinder 13 is hinged to the inner wall of the shield body 6 , and the other end is hinged to the upper end of the inner sleeve 15 of the shield.

[0064] Other structures of this embodiment are the same as Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com