A plug-in modular steel structure connection node with reset function

A technology for connecting nodes and steel structures, applied in building components, building structures, protective buildings/shelters, etc. It can solve the problems of large damage, weak seismic performance, and large residual deformation at the intersection of beams and columns, and achieve high performance. Construction accuracy, reliable performance and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

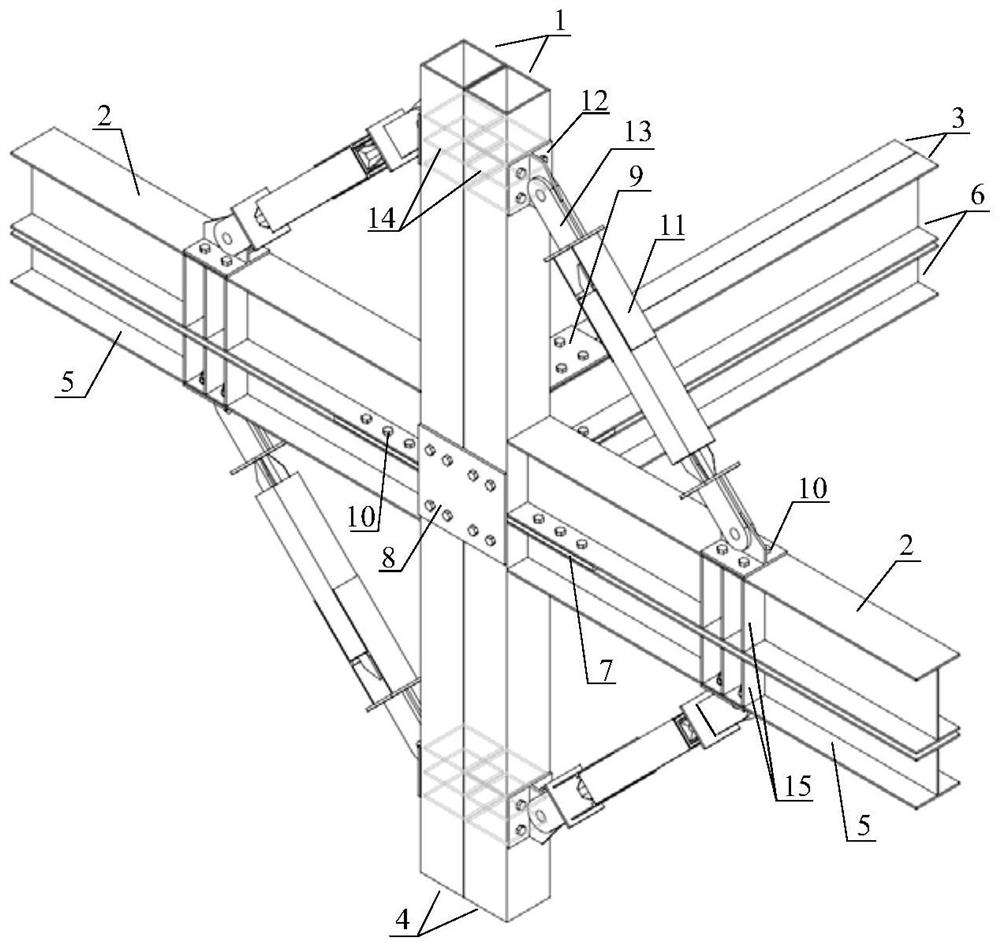

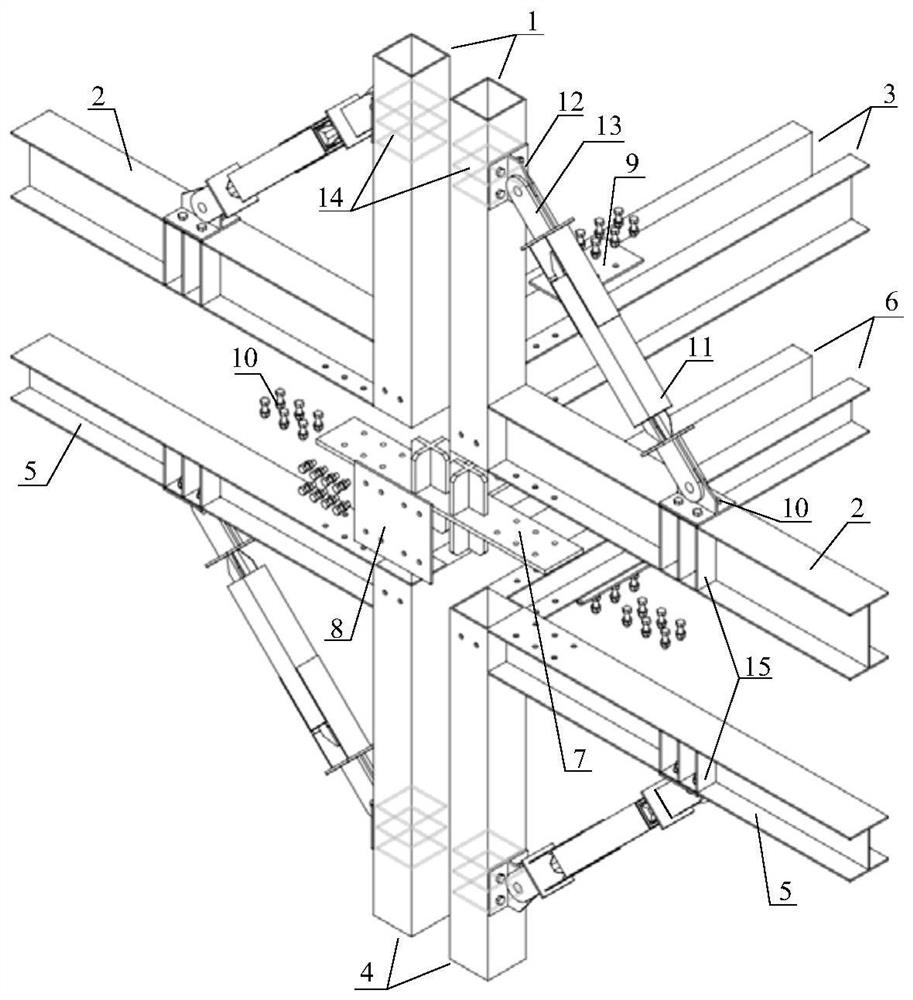

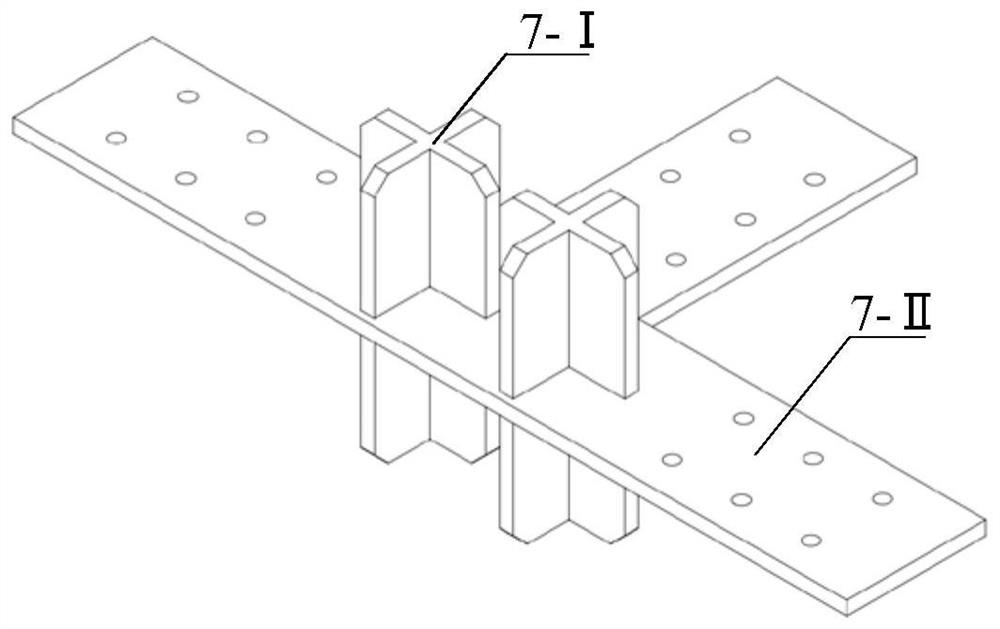

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0034] Such as Figure 1-10 As shown, the plug-in modular steel structure connection node with reset function includes the modular steel structure connection node and self-resetting arm brace 11 . The modular steel structure connection node includes two upper module units, two lower module units, a cross-type bolt connector 7 , a vertical cover plate 8 , a horizontal cover plate 9 and high-strength bolts 10 . The upper module unit includes the upper box section module column 1, the upper I-shaped section module beam 2, the upper channel section module beam 3, the upper I-section module beam 2 and the upper channel section module beam 3 are vertically welded on the upper box On the adjacent side of the end of the shaped section modular column 1; the lower modular unit includes the lower box section modular column 4, the lower I-shaped section modular beam 5, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com