Narrow long plane concrete honeycomb type space lattice box type structure and manufacturing method

A space grid and box-type structure technology, which is applied to building components, building structures, floors, etc., can solve the problems of large amount of structural materials, no three-dimensional space force transmission characteristics of floors, and small structural space effects, so as to achieve internal force Uniform distribution, good three-dimensional space mechanical properties, and the effect of improving lateral stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

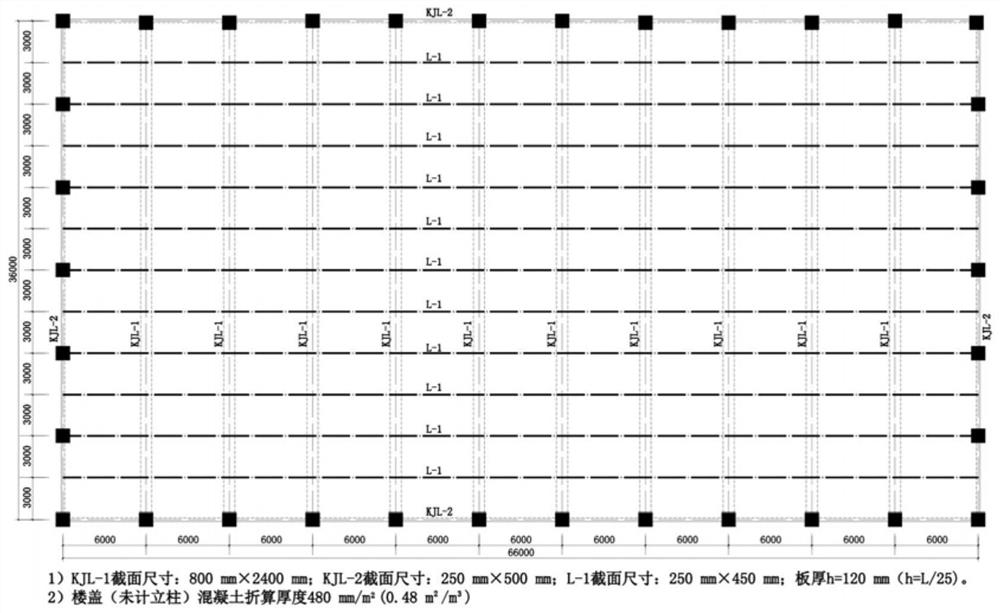

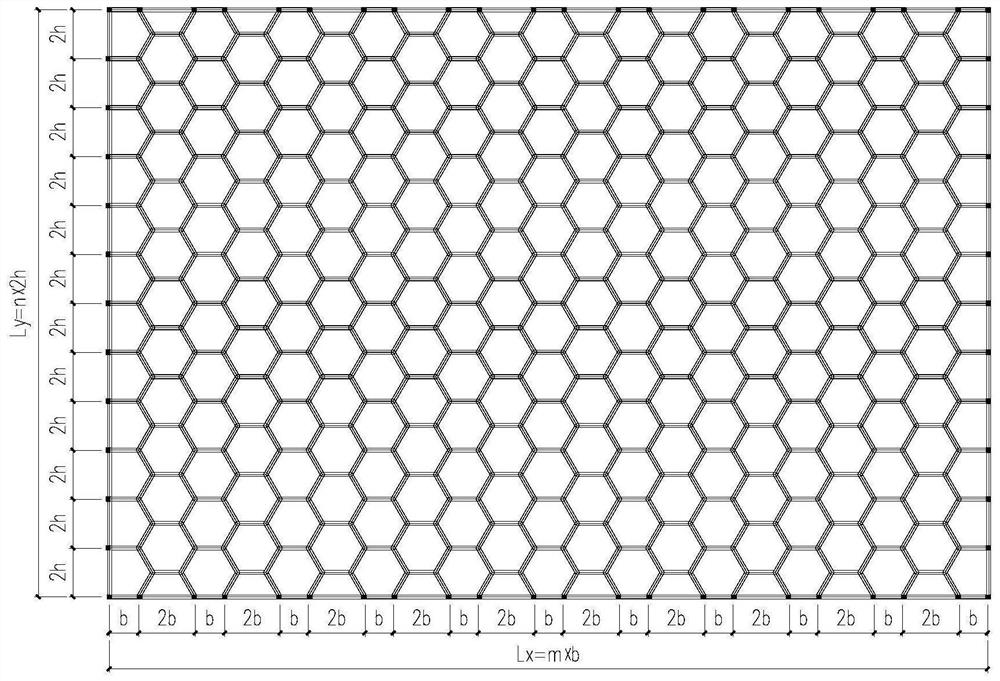

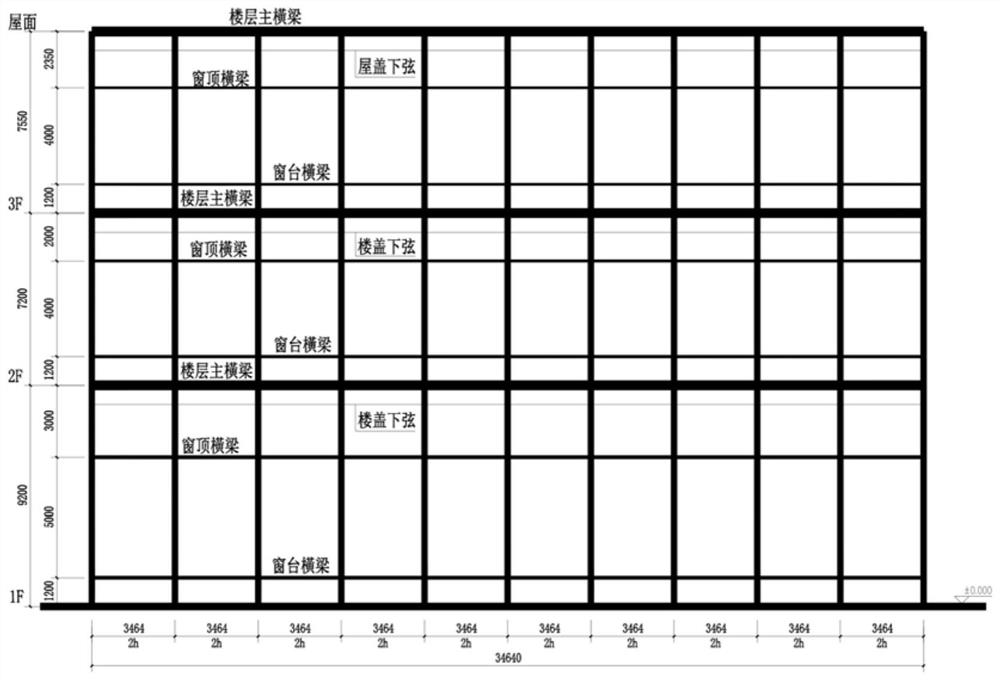

[0028] Such as Figure 1 to Figure 5 As shown, the narrow and long plane concrete honeycomb space grid box structure includes multi-layer long-span narrow and long plane concrete honeycomb hollow sandwich plate floor and concrete grid frame column, the long sides Lx and The support of the span edge Ly is rigidly connected with the surrounding concrete grid frame columns to form a space grid box system; in which, each floor of a long-span narrow and long planar concrete honeycomb hollow sandwich panel floor is divided into an upper chord and a lower chord , the lower chord layer is composed of lower chord beams to form a plurality of regular hexagonal honeycomb grids, the long side Lx of the narrow elongated plane is a multiple of the honeycomb grid side length b, and from the left and right ends in b+2b=3b mode Arranged toward the center of the long side, and the span side Ly of the narrow elongated plane is a multiple of the honeycomb grid height 2h, that is, the increase or ...

Embodiment 2

[0032] Such as figure 2 As shown, when the honeycomb grid side length b=2m, the honeycomb grid height 2h=2×bsin60°=2×1.732m=3.464m, the floor Lx=m×b=2×(5×3b)+ b=31b=62m, Ly=n×2h=12×2×1.732m=41.568m, the floor area is about 2577m 2 . The number of supports=2×5×2×2+2×11+4=66, and the number of columns is also 66.

Embodiment 3

[0034] When the honeycomb grid side length b=2m, the honeycomb grid height 2h=2×1.732m=3.464m, m=31, n=10, the floor Lx=m×b=2×(5×3b)+ b=31b=62m, Ly=n×2h=10×2×1.732m=34.64m, the floor area is about 2148m 2 . The number of supports=2×5×2×2+2×9+4=62, and the number of columns is also 62.

[0035]The ratio of the long side (Lx) to the span side (Ly), Lx / Ly=1.5~2, if the span Ly=36m, then the long side Lx=54~72m, the construction area of each floor is 1944m 2 ~2592m 2 between.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com