Circular plane large-span honeycomb type concrete open web sandwich plate floor system and construction method thereof

A large-span, honeycomb-type technology, applied to floors, building components, buildings, etc., can solve the problems of rising project cost and uneven force, and achieve the effect of light weight, saving project cost and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

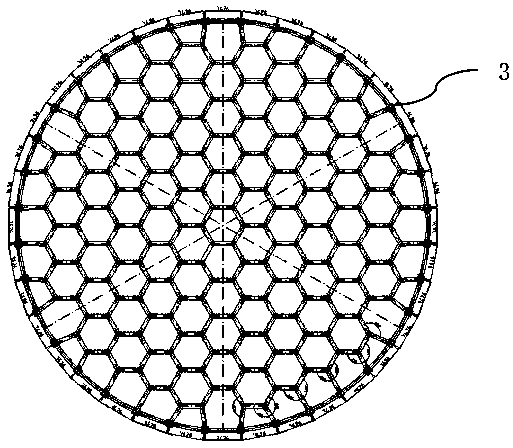

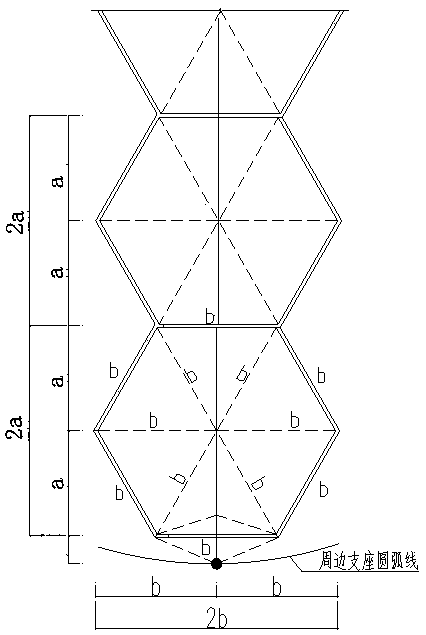

[0037] A circular planar large-span honeycomb concrete hollow sandwich slab floor is provided, which includes an upper chord layer and a lower chord layer with circular edges. A plurality of regular hexagonal grids formed by the jointing of the upper run beams 21 also includes a regular hexagonal upper string plate 22 that is superimposed on the regular hexagonal grids and cast into one body with the regular hexagonal grids.

[0038] Wherein the upper string beam 21 and the lower string beam 11 are vierendeel girders, and each lower string beam is provided with a three-pronged shear key at the junction to enhance the structural strength of the floor.

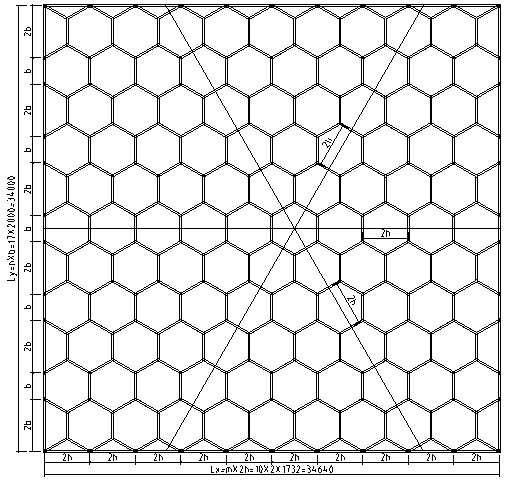

[0039] Specifically, the setting method of the regular hexagonal grids of the upper and lower chords is as follows: use the upper chord / lower chord to set a central regular hexagonal grid in the center of the upper chord / lower chord, and the periphery of the central hexagonal grid to the upper chord A number of regular hexagonal...

Embodiment 2

[0049] Provide a kind of construction method of described circular plane large-span honeycomb concrete hollow sandwich slab floor, comprising the following steps:

[0050] S1. Connect the lower string beam 11 into several regular hexagonal grids, and the grid edge of the regular hexagonal grid near the edge of the lower string layer intersects with the circular edge of the lower string layer to form a support 3, and the regular hexagonal grid setting method It is: use the lower string beam to set a central regular hexagonal grid in the center of the lower string layer, and a plurality of regular hexagonal grids are radially arranged between the periphery of the central regular hexagonal grid and the circular edge of the lower string layer. The size of the regular hexagonal grid is the same as that of the central regular hexagonal grid, and the radial pattern is as follows: except for the central regular hexagonal grid, for each additional circle of regular hexagonal grids, six ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com