A portable fiber-reinforced composite material preparation device and its use method

A fiber-reinforced, composite material technology, applied in the field of mechanical devices, can solve problems such as uneven distribution of internal stress, high labor intensity, and complex device structure, and achieve the effects of solving difficulty in tension control, improving mechanical properties, and uniform internal force distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

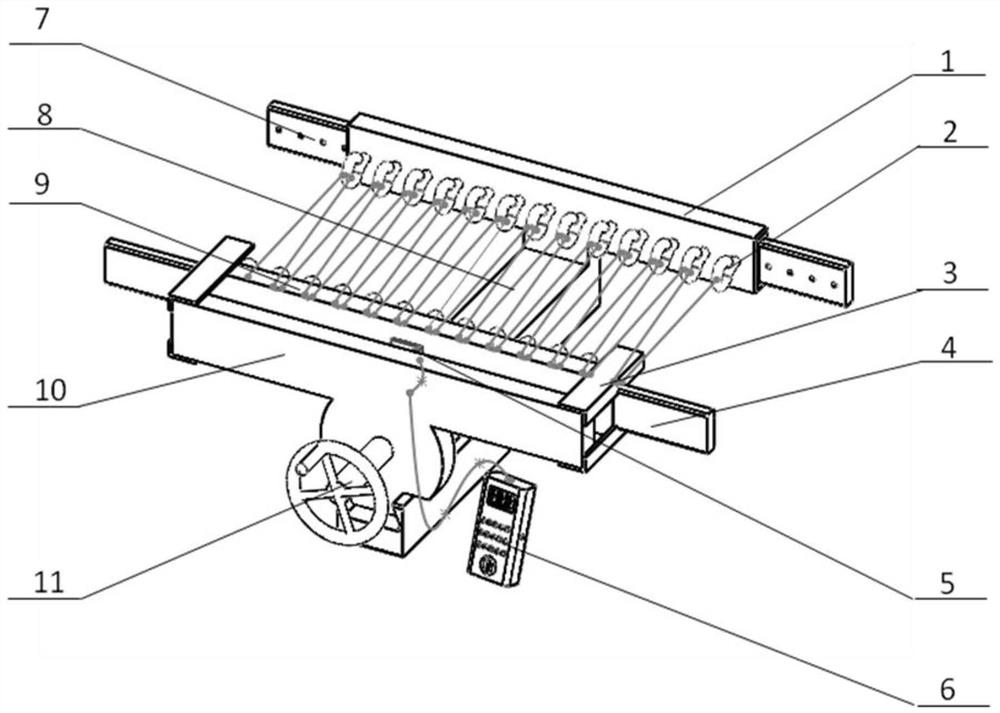

[0043] A portable fiber-reinforced composite material preparation device includes a fixed support plate, a pull ring, a slide rail, an electromagnetic inductor, a rocker, a base, a movable support plate and a pull body.

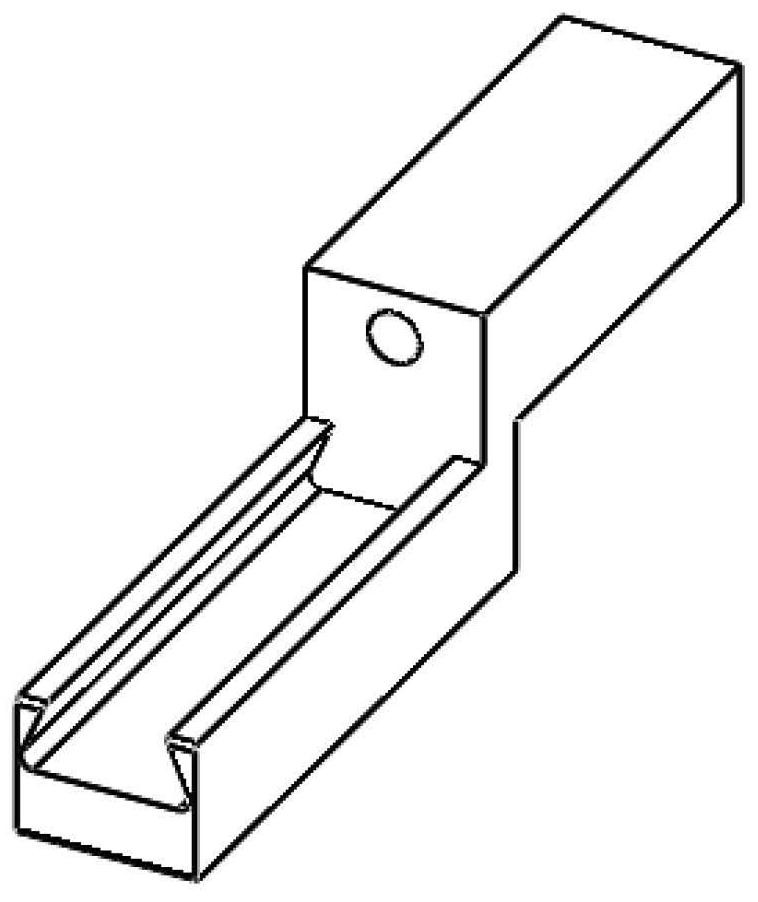

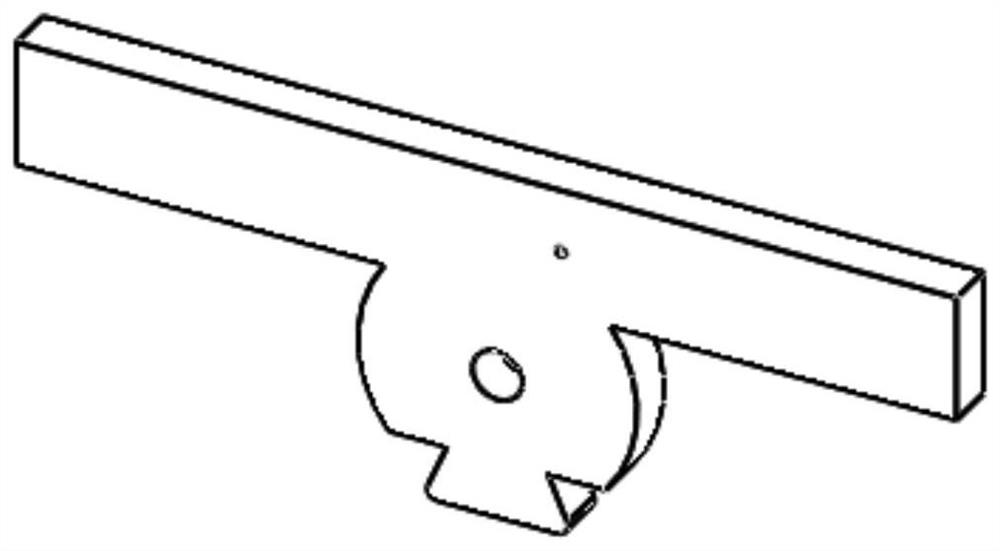

[0044] Both the fixed support plate and the movable support plate are a rectangular support plate, the two sides of the fixed support plate and the movable support plate are opposite, and evenly distributed threaded holes are arranged on the opposite sides of the fixed support plate and the movable support plate, and The positions of all the threaded holes on the fixed support plate and the movable support plate correspond to each other. Each pull ring is threaded. The pull rings are respectively fixed by the threads on the fixed support plate and the movable support plate. The two opposite ends of the pull rings An opening is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com