Metal glass surface in-situ metallization multilayer eutectic bonding method and device based on electrogenerated cationic conduction

A conductive glass and multi-layer stacking technology, which is applied in lamination devices, chemical instruments and methods, lamination, etc., can solve the problems of not having eutectic bonding ohmic contact and excellent heat dissipation, so as to reduce residual thermal stress, The effect of simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, and are not limited to the combinations of the following embodiments.

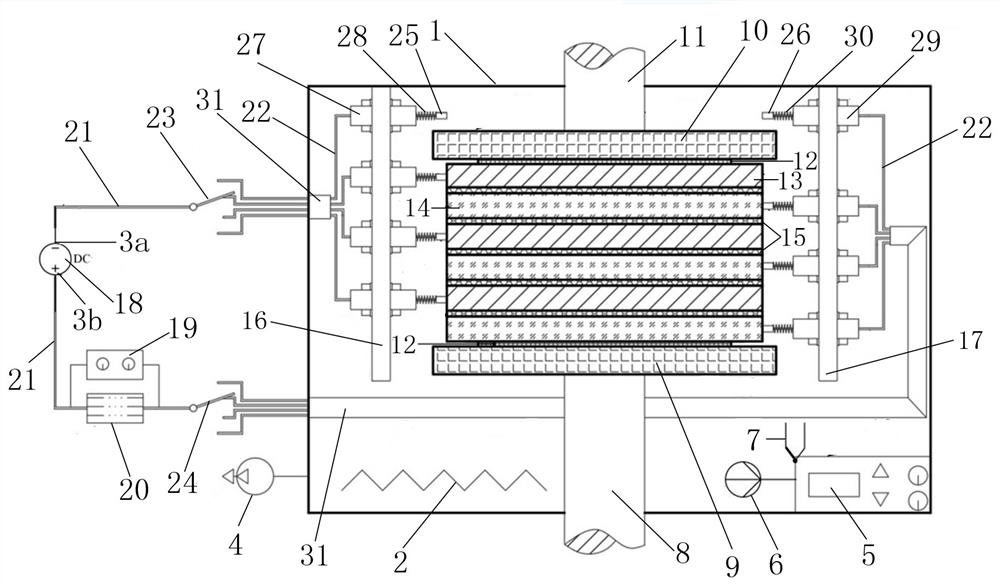

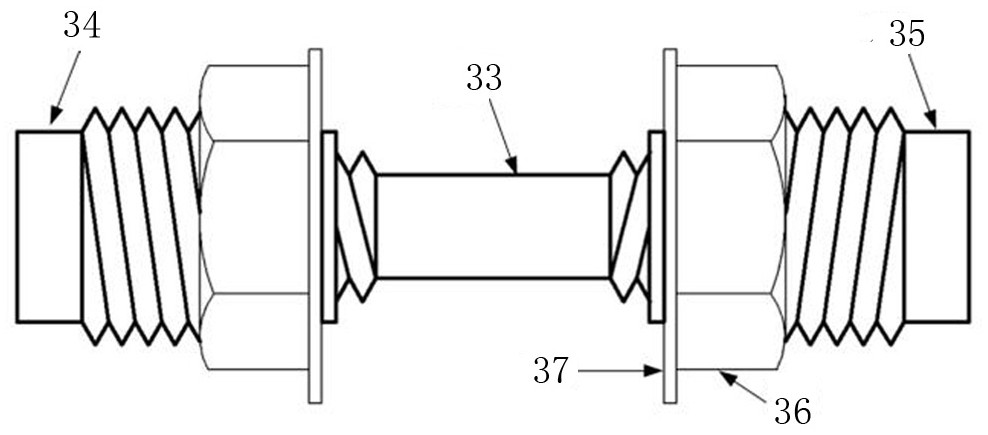

[0033] A metal / glass surface in-situ metallized multi-layer stack bonding device based on electro-cationic conduction, including a heating system for providing a bonding heat source for the test piece to be connected, and a static electricity for applying a DC electrostatic field to the test piece to be connected Field application system, a pressure loading system for loading axial pressure on the test piece to be connected. The heating system for preheating the test pieces to be bonded includes a vacuum bonding furnace body, a heating unit, a thermocouple placed in the heating furnace, a thermocouple vacuum gauge, a vacuum pump, and a temperature and vacuum degree control system. The DC electrostatic field application system includes a DC power supply, electrode leads, elec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com