Sulfur elementary substance preparation system and method based on power plant desulfurization wastewater

A desulfurization wastewater and preparation system technology, applied in the direction of sulfur preparation/purification, separation methods, chemical instruments and methods, etc., can solve the problems of high treatment costs and difficult wastewater treatment, and achieve high purity, good market prospects, and efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

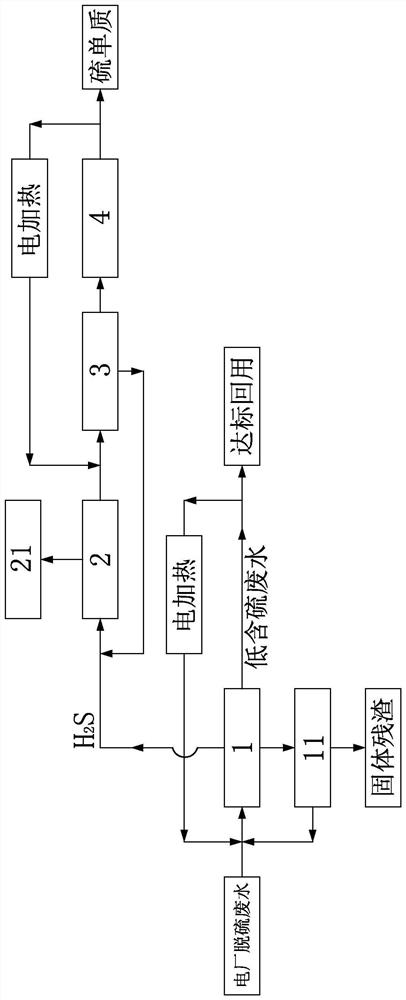

[0023] see figure 1 The shown sulfur elemental preparation system based on power plant desulfurization wastewater, which at least includes sequentially connected biological anaerobic reaction units 1, H 2 S absorption unit 2, biological oxidation reaction unit 3 and centrifugal dehydration unit 4.

[0024] The biological anaerobic reaction unit 1 can adopt an anaerobic reaction tower. The inlet of the anaerobic reaction tower is passed into the desulfurization wastewater of the power plant, and the H generated after the biological anaerobic reaction 2 S is discharged through the gas outlet and passed into the subsequent H 2 S absorption unit 2, the generated low-sulfur wastewater is discharged through the liquid outlet. The destination of low-sulfur waste water is divided into two routes, one route is further treated and reused in the factory, and the other route is electrically heated and then returned to the anaerobic reaction tower to participate in the reaction. The co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com