Device testing structure and its manufacturing method and testing method

A technology for testing structures and manufacturing methods, applied in semiconductor/solid-state device testing/measurement, single semiconductor device testing, semiconductor/solid-state device manufacturing, etc., to solve problems such as inability to form shadow effects and leakage currents that cannot be measured

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The device testing structure and its manufacturing method and testing method proposed by the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments. It should be noted that the accompanying drawings are all in a very simplified form and in inaccurate scales, and are only used to facilitate and clearly assist the purpose of explaining the embodiments of the present invention. Furthermore, the structures shown in the drawings are often part of the actual structure. In particular, each drawing needs to show different emphases, and sometimes different scales are used.

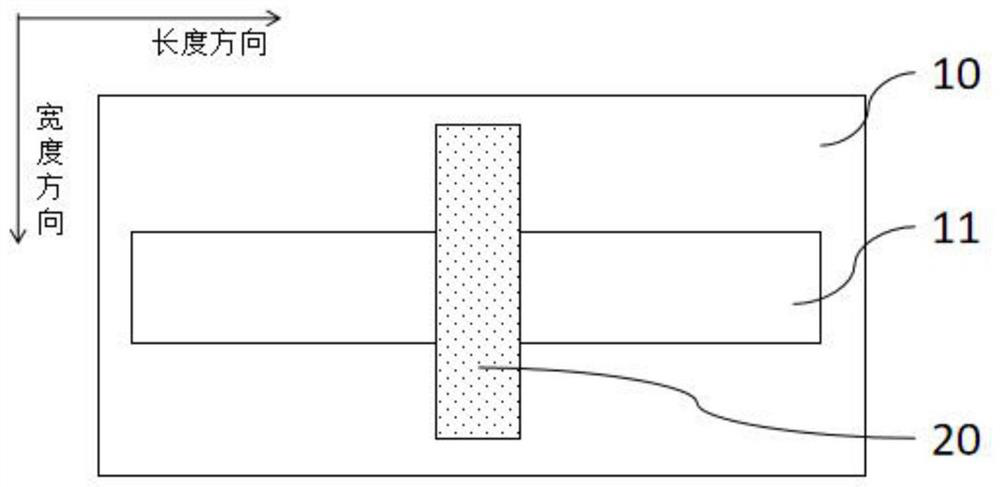

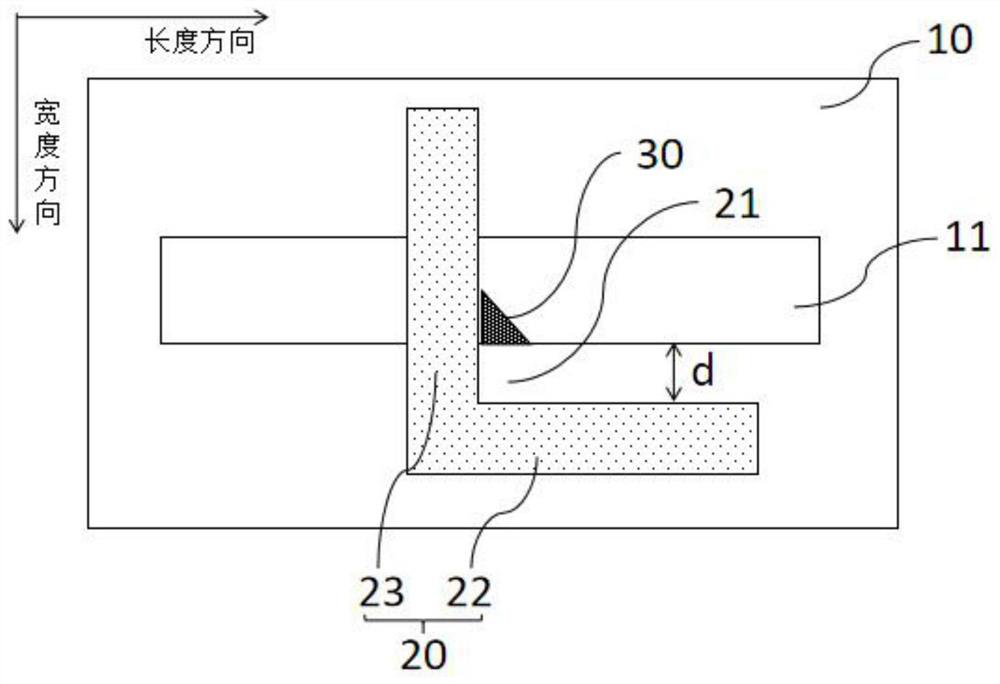

[0032] In the prior art, device test structures such as figure 1 As shown, an active region 11 is formed in a semiconductor substrate 10, and a polysilicon layer 20 is formed on the substrate 10. At least part of the polysilicon layer 20 covers part of the surface of the active region 11, and the polysilicon Layer 20 is inline. Beca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com