Check valve surface pressure evaluation method, evaluation device, equipment and storage medium

A surface pressure and check valve technology, which is applied in the field of kitchen appliances, can solve the problems such as the inability to measure the accuracy of the numerical simulation of the pressure on the inner wall of the check valve of the range hood, and achieve the effect of ensuring reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

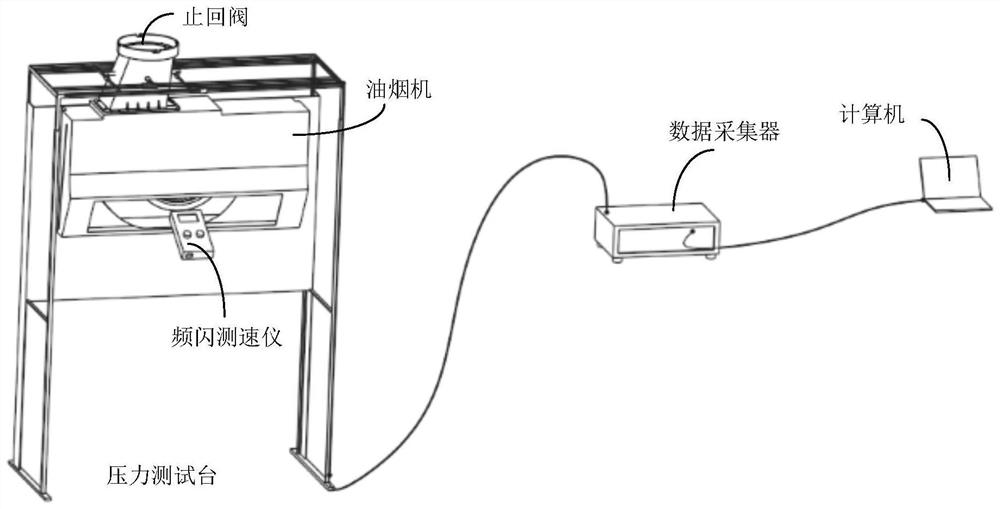

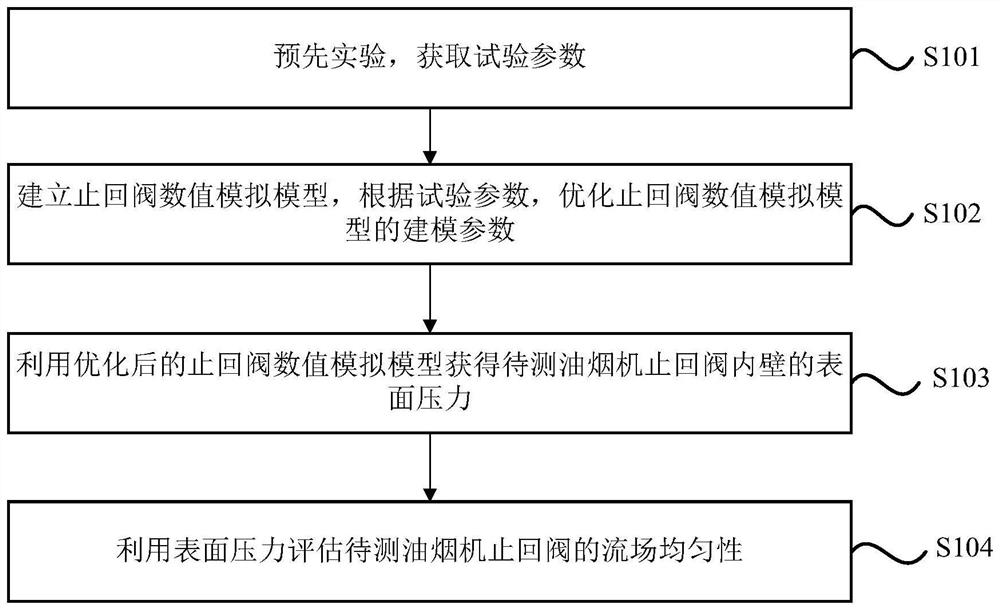

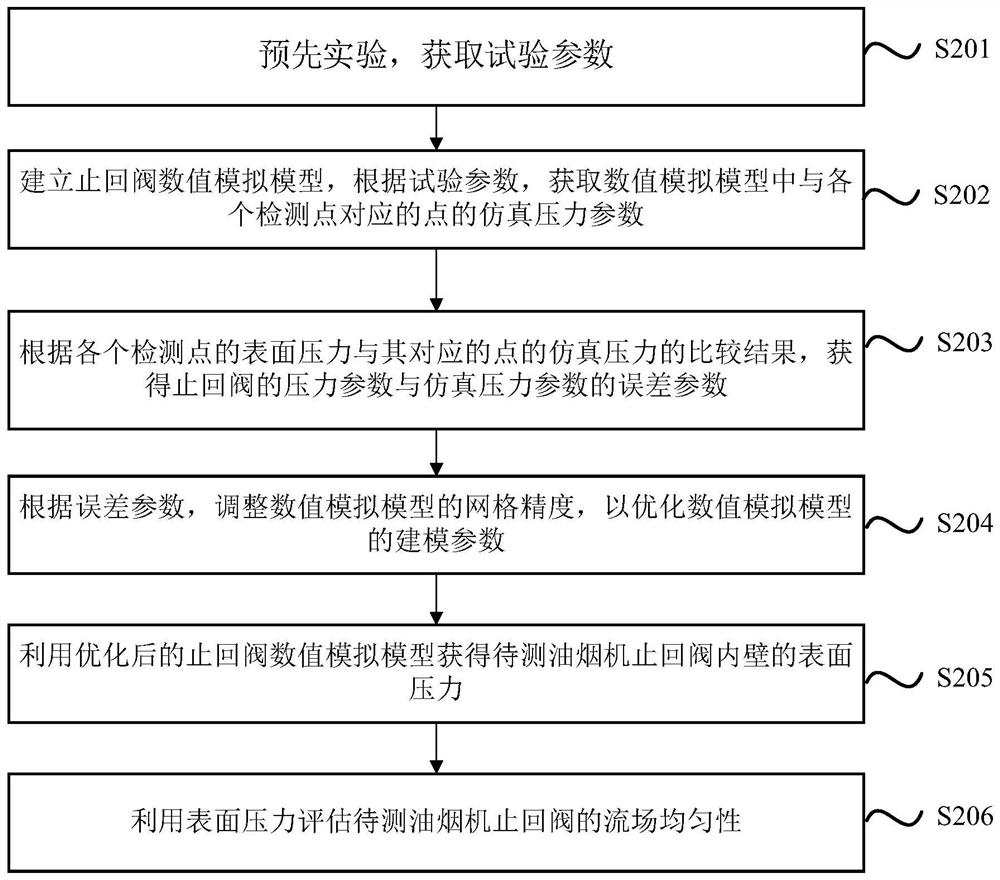

[0065] figure 1 A schematic diagram of a device for evaluating the surface pressure of a range hood check valve provided by the present invention; figure 2 A schematic flowchart of the method for evaluating the surface pressure of a check valve provided by the present invention. The pre-test was carried out with an evaluation device for the surface pressure of the check valve of the range hood, which includes a pressure test bench with a pressure sensor, a stroboscopic tachometer for monitoring the rotational speed, a data collector for integrated data, and a computer for post-processing analysis; The simulation software is used to establish and optimize the numerical simulation model of the check valve. The numerical simulation model of the check valve can be used for the simulation test of the surface pressure of the check valve of the range hood to be tested. combine figure 1 and figure 2 As shown, the method for evaluating the surface pressure of the check valve provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com