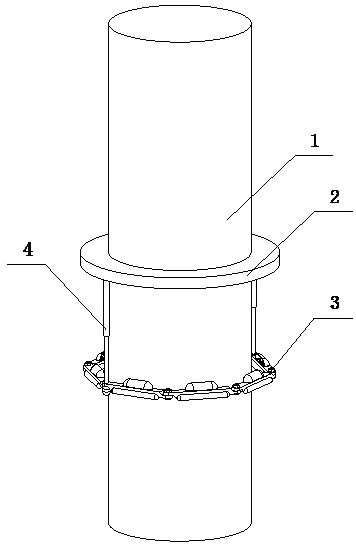

Intertidal zone corrosion detection device for offshore wind turbine tower tube

A technology for offshore wind turbines and corrosion detection, applied in measuring devices, wind power generation, motor vehicles, etc., can solve the problems of large use limitations, easy peeling, falling off, immersion in sea water, etc., to ensure service life and equipment safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

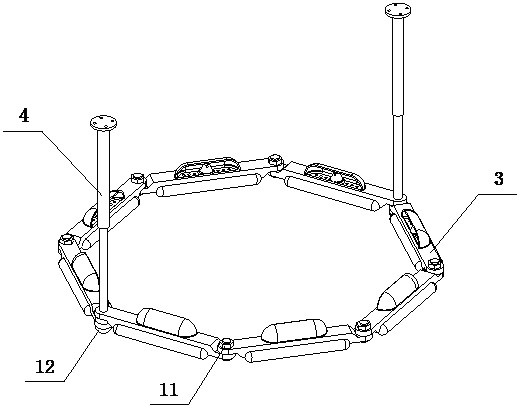

[0015] The intertidal zone corrosion detection device of the offshore wind power tower tube of the present invention is realized in the following way: the intertidal zone corrosion detection device of the offshore wind power tower tube of the present invention includes a baffle plate (2), a floating element (3) and a positioning A rod (4), a plurality of floating elements (3) are connected end to end by bolts (11) to form a semi-floating ring, and two semi-floating rings are connected by two telescopic positioning rods (4) to form a full floating ring, The baffle platform (2) is located above the entire floating ring, and the positioning rod (4) is connected with the baffle platform (2); the positioning rod (4) is provided with a floating block (12); the floating element ( 3) It includes a floating plate (14), a protective cover (5), a camera (6), a diversion groove (7), an air bag (9), and a diversion hole (10), and one end of the floating plate (14) has a Avoidance groove, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com