Special-shaped current collector, PEM water electrolysis hydrogen production device and water electrolysis hydrogen production method

A technology for current collectors and water electrolysis, applied in the electrolysis process, electrolysis components, electrochemical generators, etc., can solve the problems of difficult assembly, increased internal resistance of the battery, complex components, etc., to achieve convenient and simple installation and reduce internal resistance. , the effect of reducing device composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The preparation and processing methods of the present invention include thermal sintering of porous materials, etching, mechanical processing, stamping and the like.

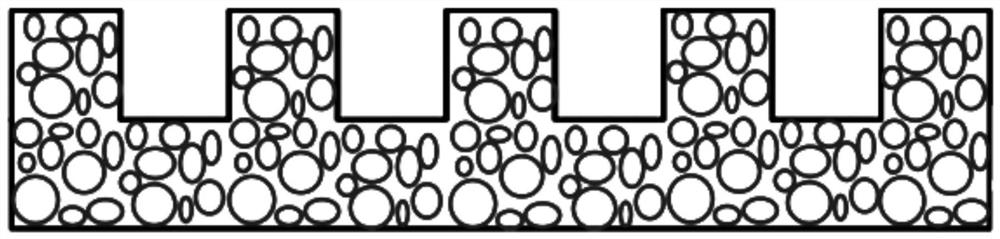

[0047] One of the features of the device form of the present invention is: the special-shaped current collector is made of porous titanium material with a porosity of 0.7, the overall thickness is 1 mm, the surface flow channel is in the form of parallel flow channels, and the ridge width of the flow channel is 1 mm. The ridges are spaced 1 mm apart and have a depth of 0.5 mm.

[0048] The second feature of the device form of the present invention is: the special-shaped current collector is made of porous titanium material with a porosity of 0.7, the overall thickness is 0.5mm, and it adopts the form of straight perforation, and the hole type is a circular hole with a diameter of 400 μm, uniform Distributed to achieve a surface porosity of 0.6.

[0049] The third feature of the device form of the present...

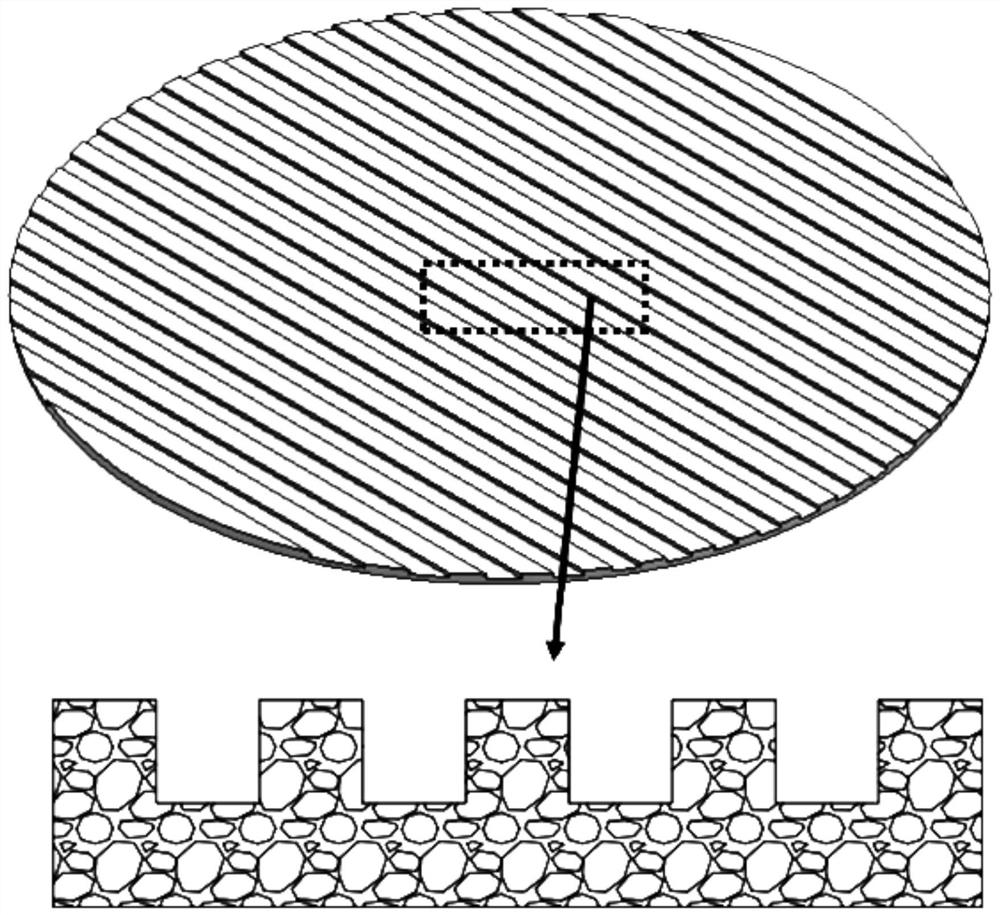

Embodiment 1

[0054] refer to figure 1 , which shows a special-shaped current collector made of porous titanium material with parallel flow channels according to one embodiment of the present invention. The whole part is 60mm long, 30mm wide and 1mm high. The runner adopts the form of parallel runner, the ridge width is 1mm, the runner width is 1mm, and the depth is 0.5mm. The porosity of the porous titanium material used is 0.7, and the processing method is integral thermal sintering.

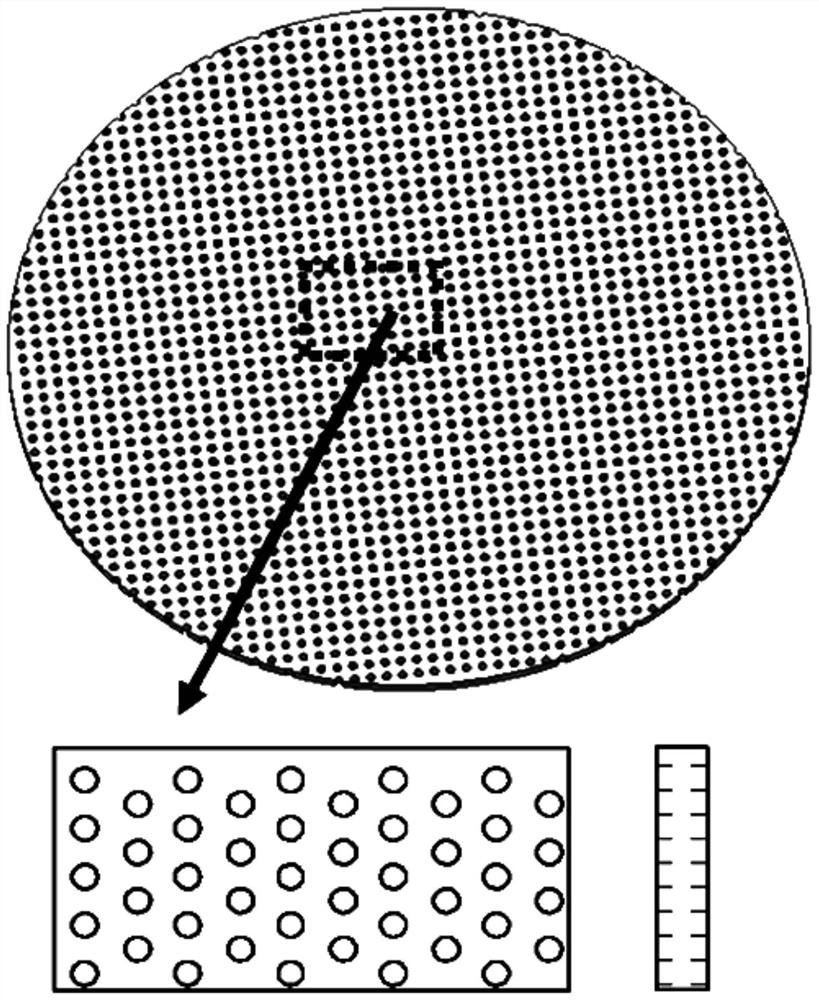

Embodiment 2

[0056] refer to figure 2 , which shows a special-shaped current collector made of porous titanium material with straight through holes in one of the embodiments of the present invention. The whole part is 60mm long, 30mm wide and 0.5mm high. The porosity of the porous titanium material used is 0.7, and the processing method is integral thermal sintering. On this basis, through the design of the mask and photolithography, a circular hole with a diameter of 400 μm is obtained. Compared with the porosity of the overall surface area, the porosity is 0.6, and the required straight through-hole special-shaped current collector is obtained through etching.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com