Bamboo chip end machining equipment

A kind of processing equipment and bamboo chip technology, which is applied in the field of bamboo chip end processing equipment, can solve the problems of high labor intensity, low work efficiency, low quality and dimensional stability of bamboo chips, etc., and achieve a stable processing and forming state and not easy to damage , the effect of stable state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in detail below in conjunction with accompanying drawing:

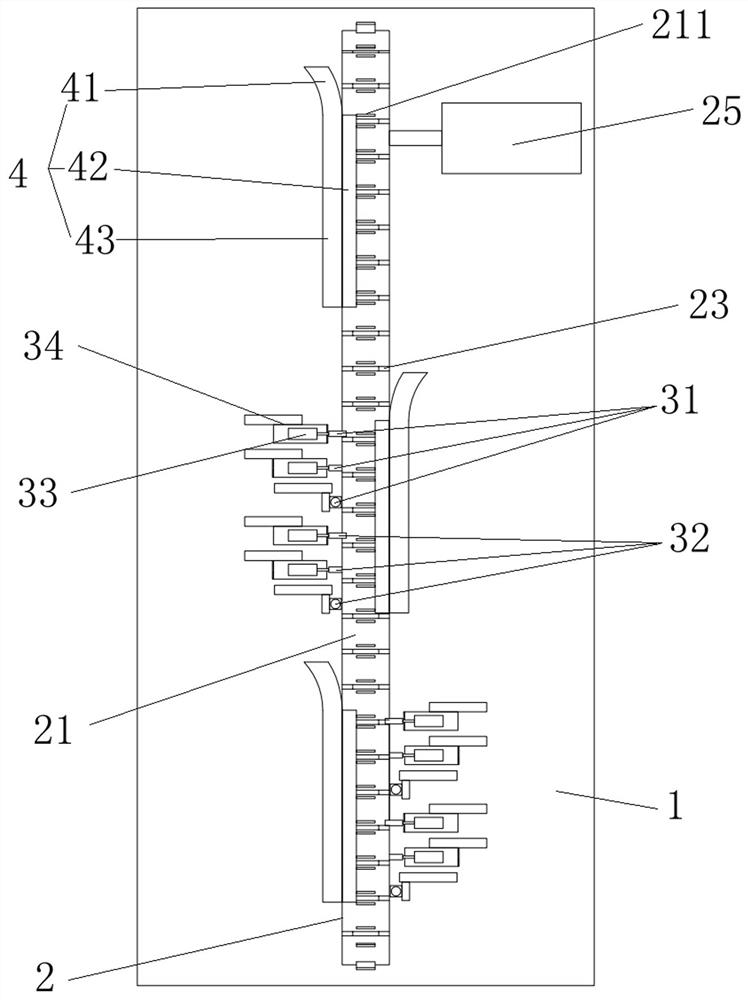

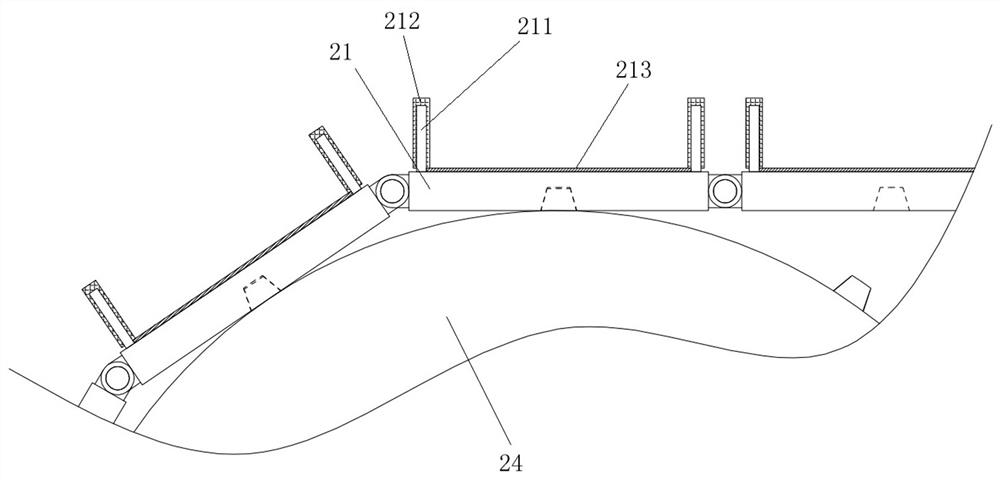

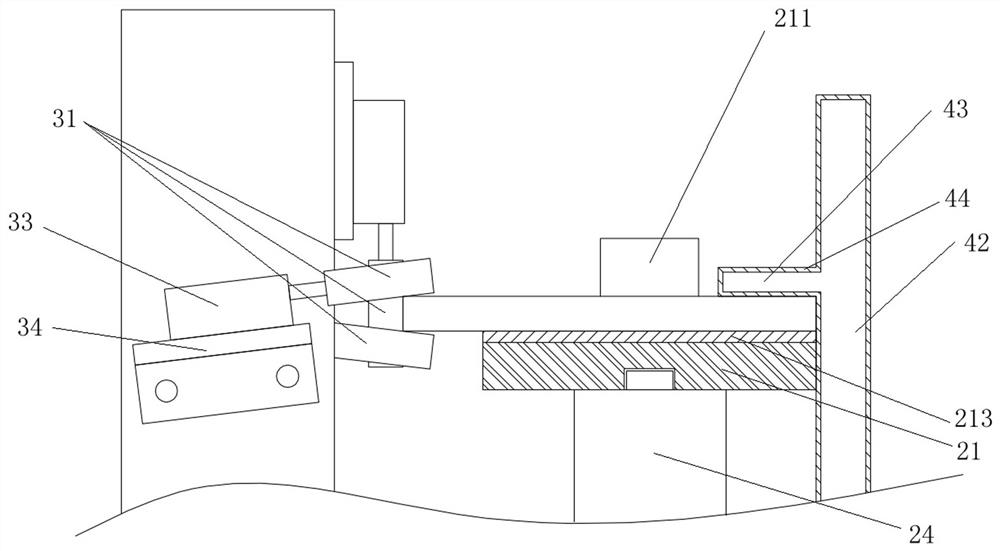

[0023] Such as figure 1 , 2 , a kind of end processing equipment of bamboo chip shown in 3, comprises table-top support 1, on the support 1 being upstream to downstream extension for conveying assembly 2 that is used for conveying bamboo chip and along the direction that conveying assembly 2 extends and arranges successively A grinding and polishing assembly, each grinding and polishing assembly includes a plurality of grinding parts 31 and polishing parts 32 driven by a drive motor 33, the grinding part 31 in each grinding and polishing assembly is positioned at the upstream side of the polishing part 32, the grinding parts 31 and the polishing The piece 32 is connected to the support 1 through an angle adjustment device 34 and points to the bamboo pieces on the conveying assembly 2 .

[0024] In this embodiment, the conveyor assembly 2 includes a conveyor belt 22 composed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com