Embedded groove type clamp spring assembly and method for drilling hard alloy materials by using embedded groove type clamp spring assembly

A technology of hard alloy and circlip, which is applied in the direction of boring/drilling, drilling/drilling equipment, metal processing equipment, etc. It can solve the problems of damage to parts, inconvenient disassembly, breakage, etc., and achieves favorable The effect of processing, complete appearance and stable state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further elaborated below by describing a preferred specific embodiment in detail in conjunction with the accompanying drawings.

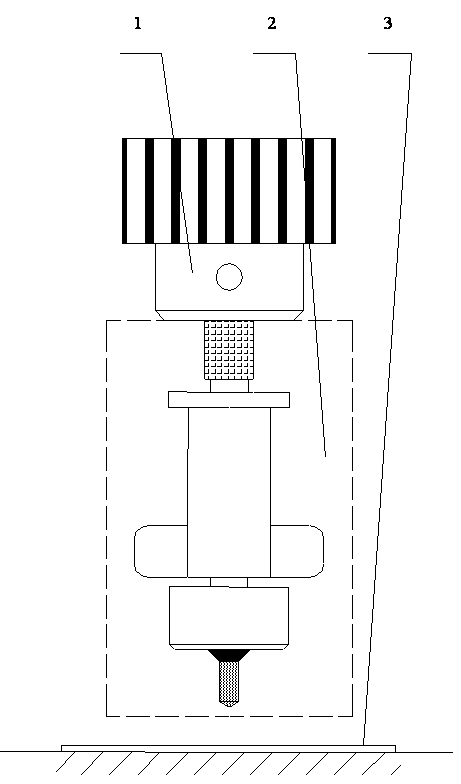

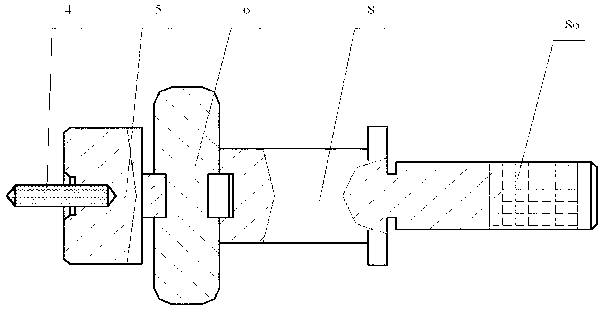

[0046] Such as figure 1 with figure 2 As shown, the recessed snap ring assembly 2 includes: a drill bit 4, in this embodiment, the drill bit 4 is made of tungsten steel material; the top sleeve 5 connected with the drill bit 4; the rod connected with the top sleeve 5 through interference fit Body part 8, the outer wall of the shaft part 8 is clamped by the external wrench drill chuck 1, so as to fix the embedded groove type circlip assembly to drill the hard alloy material with a thickness not greater than 5mm; set it on the top kit through the embedded groove 5 and the snap ring positioning piece 6 between the shaft part 8. In this embodiment, both the top sleeve 5 and the shaft part 8 are made of Cr12 steel and heat-treated to obtain higher surface hardness and strength.

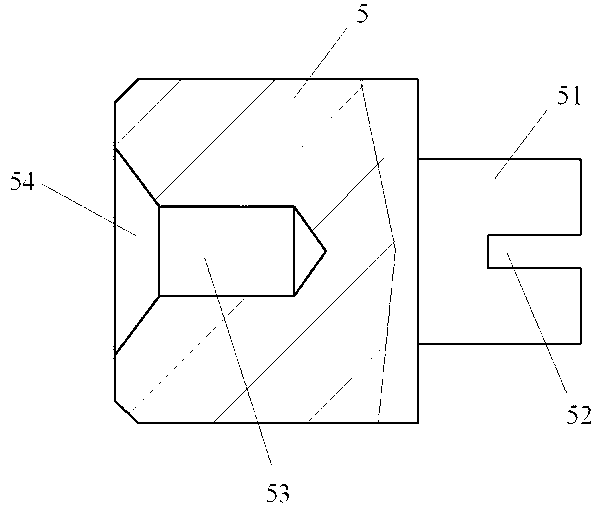

[0047] Among them, such as image...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com