Impact-resistant and wear-resistant self-protection flux-cored wire

A flux-cored wire, wear-resistant technology, applied in welding equipment, welding media, welding/cutting media/materials, etc., can solve the problems of increased cost, complex formula, cumbersome production process, etc., to save production cost and simple formula , The effect of simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

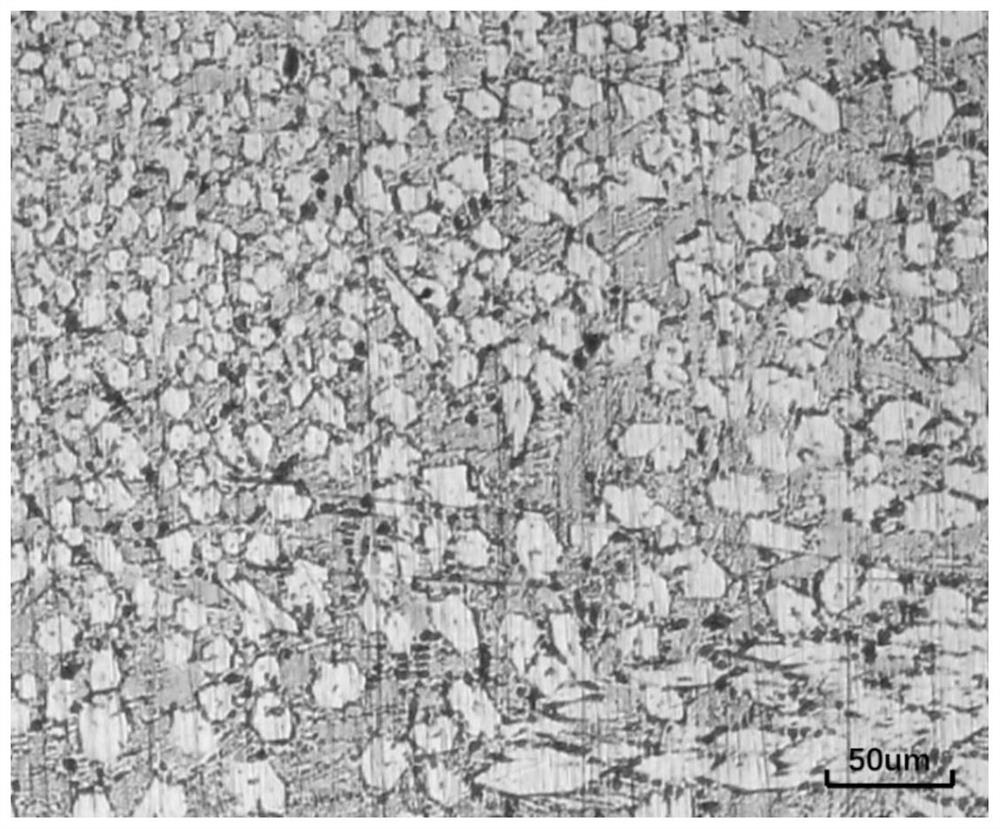

Embodiment 1

[0041] This embodiment provides an impact-resistant and wear-resistant self-protecting flux-cored welding wire. The flux-cored welding wire includes cold-rolled low-carbon steel strip and powder, and the powder is calculated as a percentage of the total mass of the flux-cored wire The composition includes: 37% high-carbon ferrochromium powder, 2% high-carbon ferromanganese alloy powder, 5% ferroboron powder, 0.6% ferromolybdenum powder, 0.1% nickel powder, 1.5% microcrystalline graphite powder, 1% rare earth element, oxidation Bismuth 0.3%, silicon calcium powder 2%. The filling factor is 49.5%.

[0042] Among them, the high-carbon ferrochromium alloy powder requires a carbon content of 8%, and the chromium content is 70%; the high-carbon ferromanganese alloy powder requires a carbon content of 8%, and the manganese content is 75%; The molybdenum content of the powder is 60%, the nickel powder requires 99.5% nickel, the microcrystalline graphite powder contains 99% carbon, th...

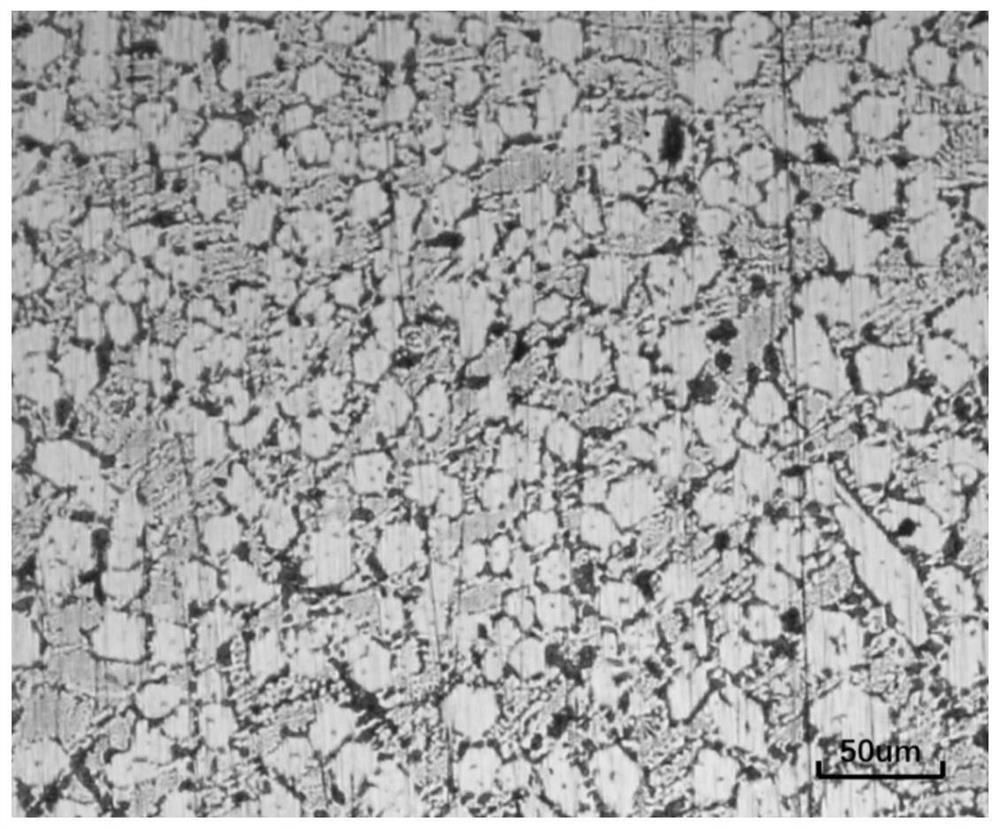

Embodiment 2

[0047] This embodiment provides an impact-resistant and wear-resistant self-protecting flux-cored welding wire. The flux-cored welding wire includes cold-rolled low-carbon steel strip and powder, and the powder is calculated as a percentage of the total mass of the flux-cored wire The composition includes: high-carbon ferrochrome alloy powder 38%, high-carbon ferromanganese alloy powder 2%, boron iron powder 4.5%, molybdenum iron powder 1.1%, nickel powder 0.1%, microcrystalline graphite powder 1.7%, rare earth elements 1.2%. Bismuth oxide 0.2%, silicon calcium powder 1.5%. The filling factor is 50.3%.

[0048] Among them, the high-carbon ferrochromium alloy powder requires a carbon content of 6%, and the chromium content is 65%; the high-carbon ferromanganese alloy powder requires a carbon content of 8%, and the manganese content is 75%; The molybdenum content of the powder is 60%, the nickel powder requires 99.5% nickel, the microcrystalline graphite powder contains 99% car...

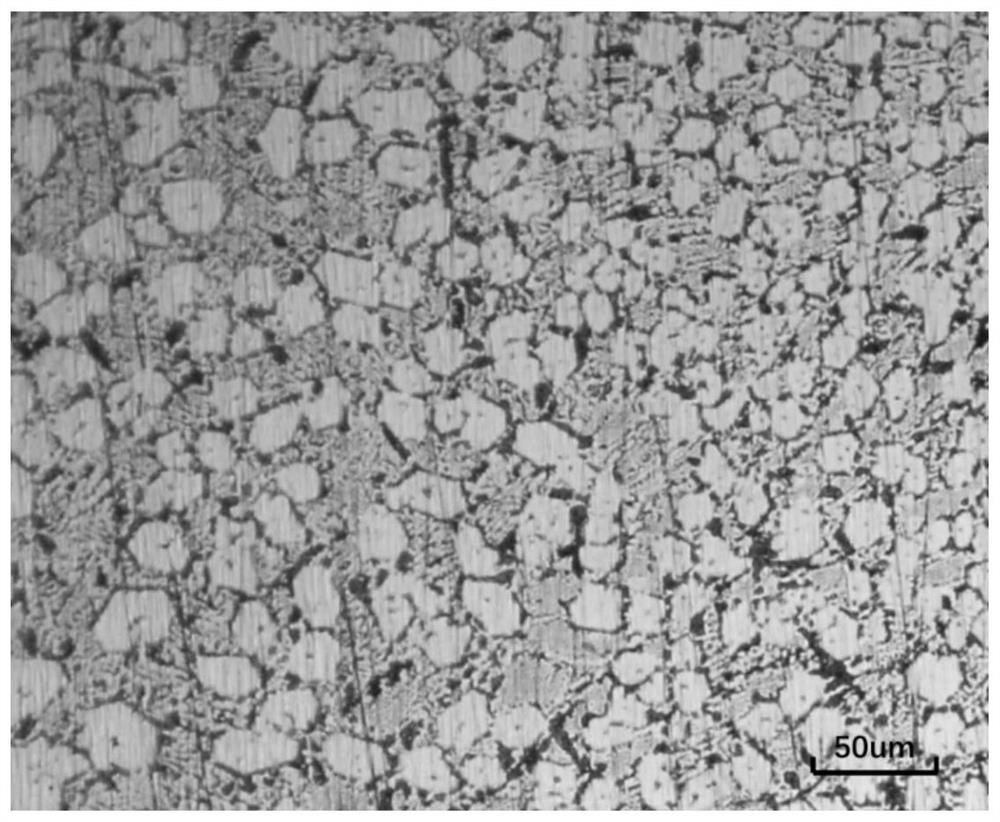

Embodiment 3

[0053] This embodiment provides an impact-resistant and wear-resistant self-protecting flux-cored welding wire. The flux-cored welding wire includes cold-rolled low-carbon steel strip and powder, and the powder is calculated as a percentage of the total mass of the flux-cored wire The composition includes: 37.6% high carbon ferrochrome powder, 2.2% high carbon ferromanganese alloy powder, 5.3% ferroboron powder, 0.8% ferromolybdenum powder, 0.1% nickel powder, 1.2% microcrystalline graphite powder, and 1% rare earth element. Bismuth oxide 0.2%, silicon calcium powder 1.5%. The filling factor is 49.9%.

[0054] Among them, the high-carbon ferrochromium alloy powder requires a carbon content of 8%, and the chromium content is 70%; the high-carbon ferromanganese alloy powder requires a carbon content of 8%, and the manganese content is 75%; The molybdenum content of the powder is 60%, the nickel powder requires 99.5% nickel, the microcrystalline graphite powder contains 99% carb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com