An On-machine Measuring Instrument for Tooth Pitch Deviation of Large Gears

A deviation measurement and measuring instrument technology, which is applied to measuring devices, instruments, and electrical devices, etc., can solve the problems of probe rotation angle signal amplification, large measurement probe size, and small leverage ratio, so as to avoid error amplification and meet practical industrial requirements. meet the requirements of the test and the effect of the test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

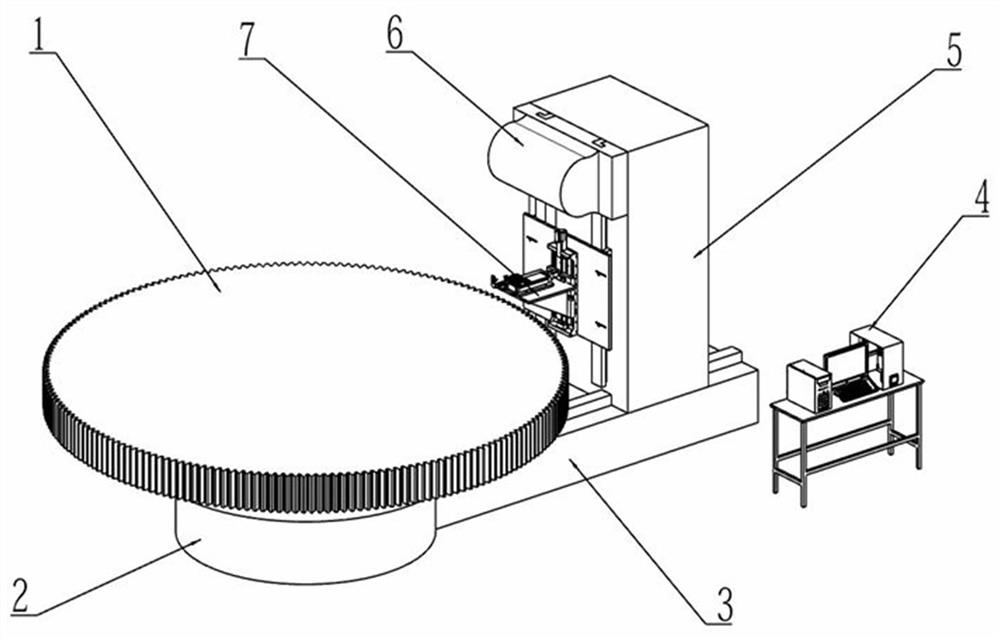

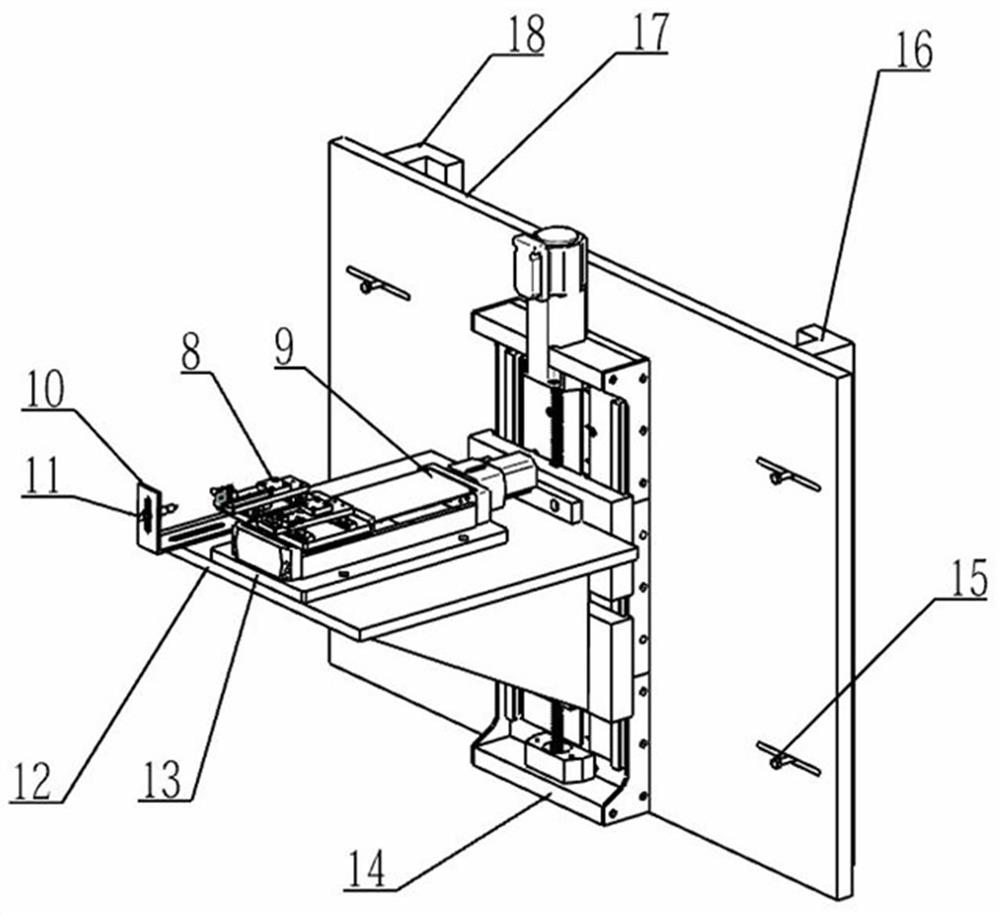

[0025] Such as Figure 1-4 As shown, the present invention includes a tooth pitch deviation measuring mechanism, a measuring mechanism reciprocating mechanism, a machine tool connection and adjustment mechanism, motion control and measurement signal processing software; it is characterized in that the tooth pitch deviation measuring mechanism is arranged on the measuring mechanism reciprocating mechanism On the top, the reciprocating motion mechanism of the measuring mechanism is set on the connection and adjustment mechanism of the machine tool.

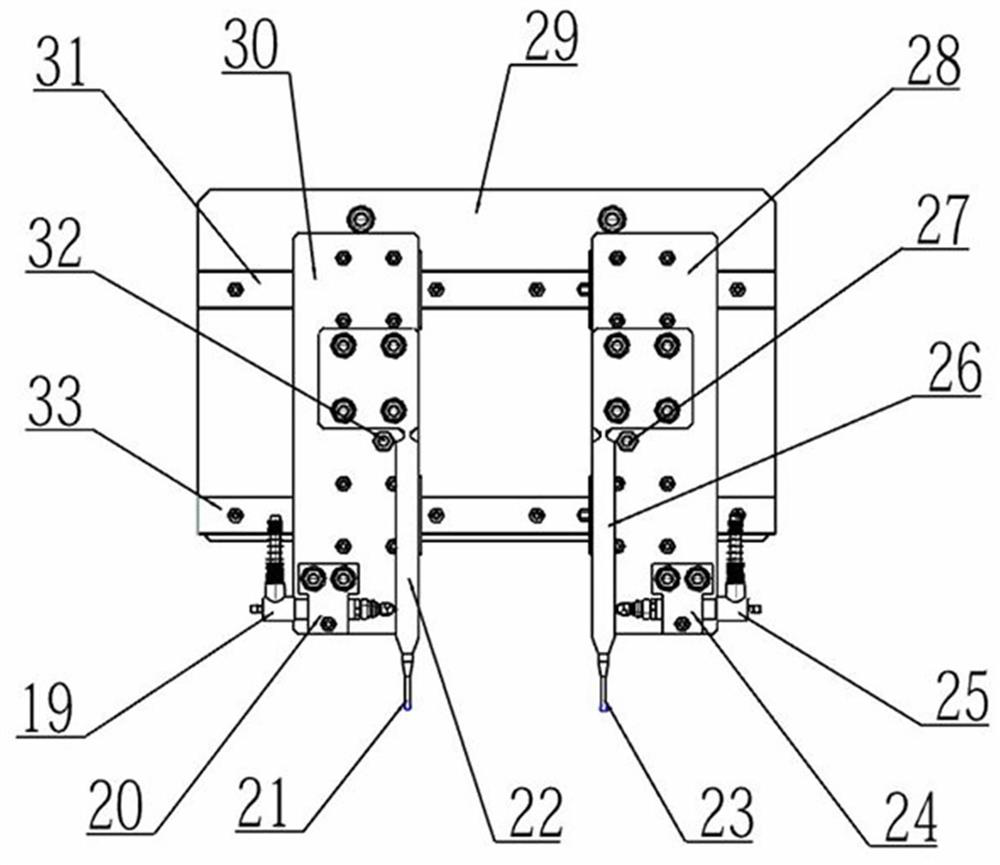

[0026] Preferably, the tooth pitch deviation measuring mechanism includes an elastic measuring rod made of spring steel material, a tooth pitch deviation measuring head, an inductance micrometer, a measuring element fixing plate, a probe center distance adjustment guide rail, and an inductance micrometer fixing plate. The block and the mounting plate of the tooth pitch measuring device; the tooth pitch deviation measuring head is se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com