A hot dirty gas self-control valve for industrial environmental protection equipment

A technology for environmental protection equipment and automatic control valves, which is applied in mechanical equipment, valve devices, valve details, etc., and can solve problems such as large resistance on the inner wall of the valve body, damage to the valve core, and affecting the flow of air.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

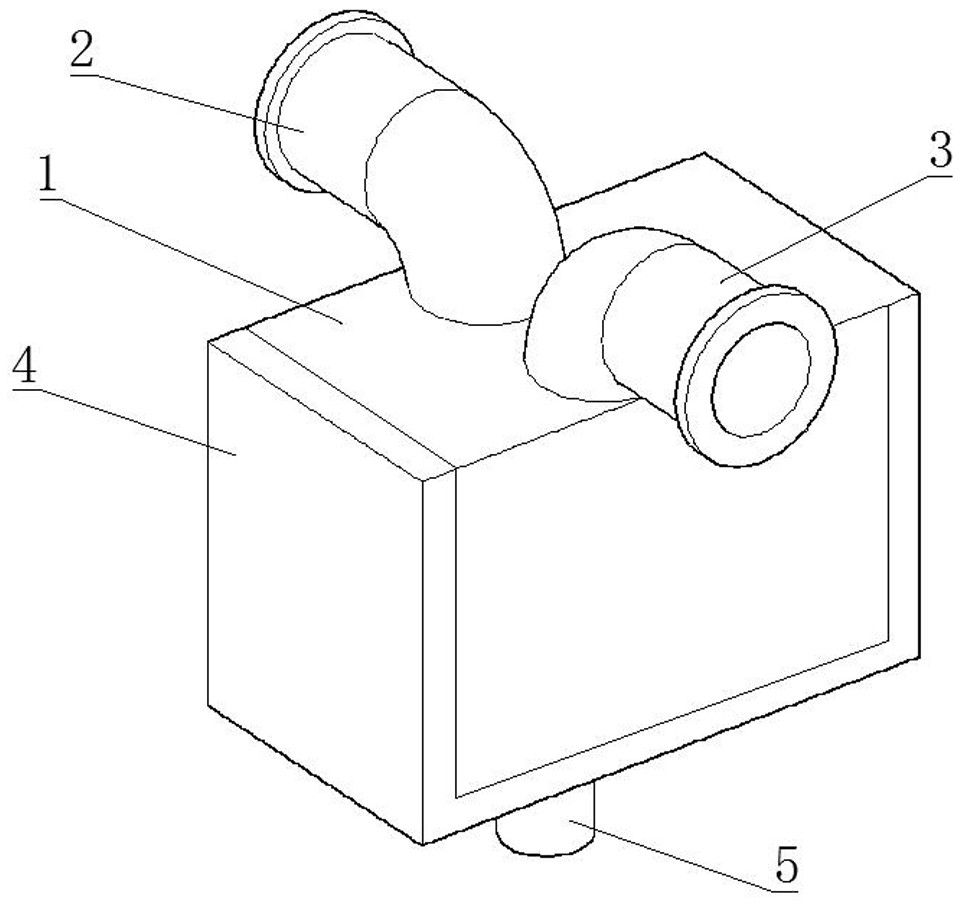

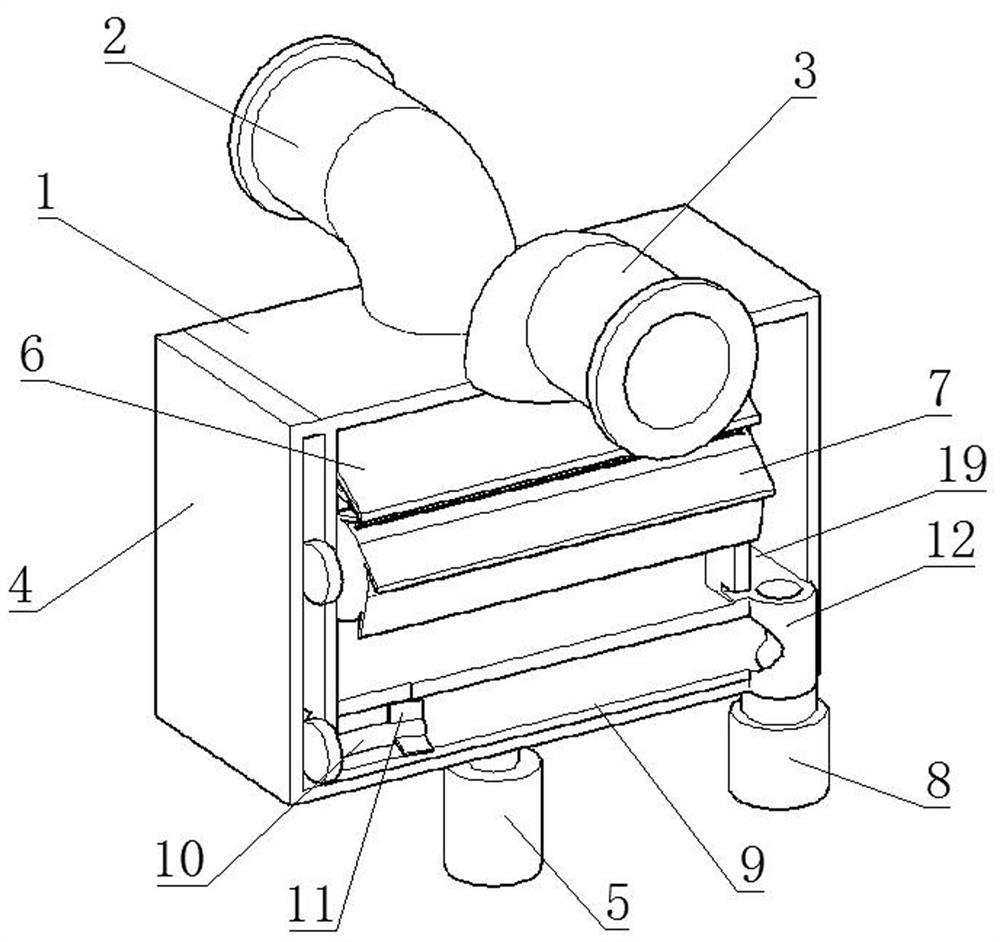

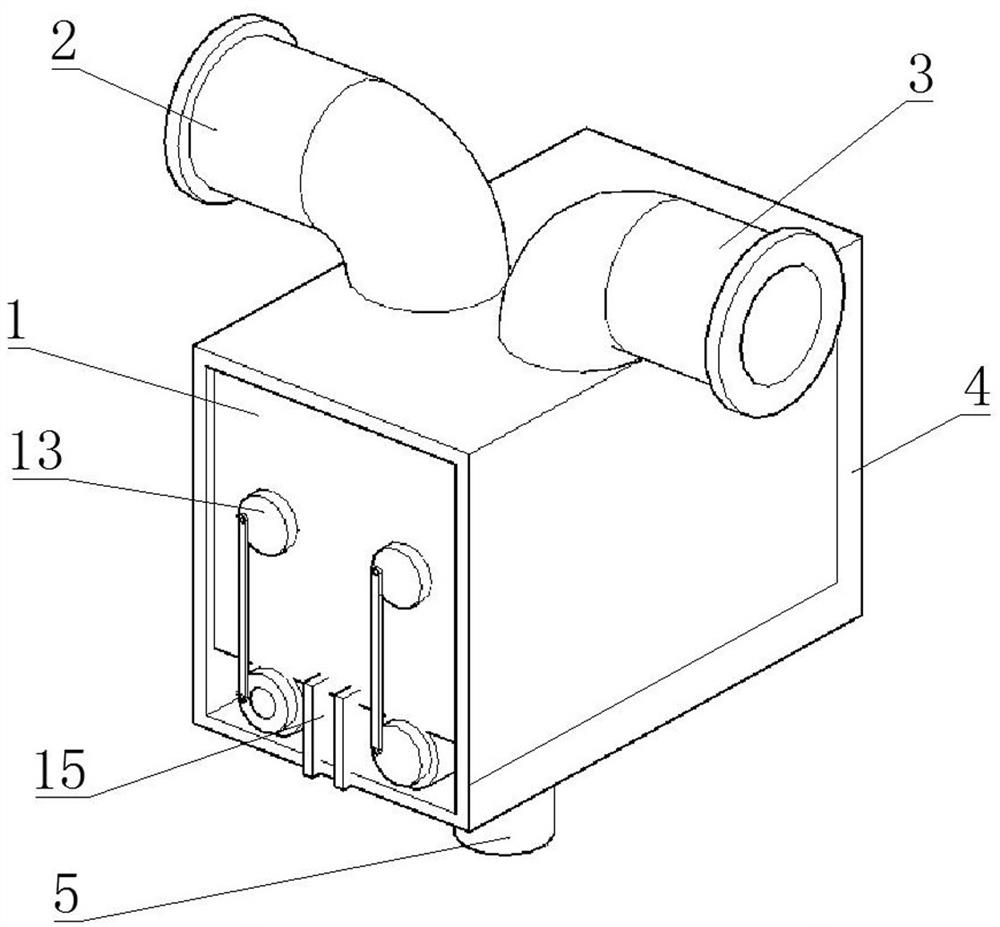

[0038] Such as Figure 1-4 As shown in the figure, a self-control valve for hot dirty gas used in industrial environmental protection equipment includes a valve body 1, and the two sides of the top of the valve body 1 are respectively connected with an intake pipe 2 and an exhaust pipe 3, which are fixed inside the valve body 1 and connected with a guide The straight plate 6 is fixedly connected with a diversion arc plate 17 at the bottom of the diversion straight plate 6, and the concave side of the diversion arc plate 17 is provided with a filter cartridge 7 that is rotatably connected with the valve body 1 through a rotating shaft 18 and a sealed bearing. The left side and the right side of the interior are symmetrical, and a water storage tank 19 is arranged at the right end of the valve body 1. The bottom end of the water storage tank 19 communicates with the interior of the valve body 1. The bottom end of the valve body 1 is slidably connected to a valve core 16, and the ...

Embodiment 2

[0041] Such as Figure 1-5 As shown in the figure, a self-control valve for hot dirty gas used in industrial environmental protection equipment includes a valve body 1, and the two sides of the top of the valve body 1 are respectively connected with an intake pipe 2 and an exhaust pipe 3, which are fixed inside the valve body 1 and connected with a guide The straight plate 6 is fixedly connected with a diversion arc plate 17 at the bottom of the diversion straight plate 6, and the concave side of the diversion arc plate 17 is provided with a filter cartridge 7 that is rotatably connected with the valve body 1 through a rotating shaft 18 and a sealed bearing. The left side and the right side of the interior are symmetrical, and a water storage tank 19 is arranged at the right end of the valve body 1. The bottom end of the water storage tank 19 communicates with the interior of the valve body 1. The bottom end of the valve body 1 is slidably connected to a valve core 16, and the ...

Embodiment 3

[0044] Such as Figure 1-6 As shown in the figure, a self-control valve for hot dirty gas used in industrial environmental protection equipment includes a valve body 1, and the two sides of the top of the valve body 1 are respectively connected with an intake pipe 2 and an exhaust pipe 3, which are fixed inside the valve body 1 and connected with a guide The straight plate 6 is fixedly connected with a diversion arc plate 17 at the bottom of the diversion straight plate 6, and the concave side of the diversion arc plate 17 is provided with a filter cartridge 7 that is rotatably connected with the valve body 1 through a rotating shaft 18 and a sealed bearing. The left side and the right side of the interior are symmetrical, and a water storage tank 19 is arranged at the right end of the valve body 1. The bottom end of the water storage tank 19 communicates with the interior of the valve body 1. The bottom end of the valve body 1 is slidably connected to a valve core 16, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com