Nozzle glue for impermeable tipping paper and preparation method thereof

A technology of tipping paper and mouth glue, which is applied in the application, manufacture of cigarettes, and monocarboxylate copolymer adhesives. It can solve the problems of low machine speed, inability to bond, and uneven glue application. High safety, good bonding performance, and low VOCs content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

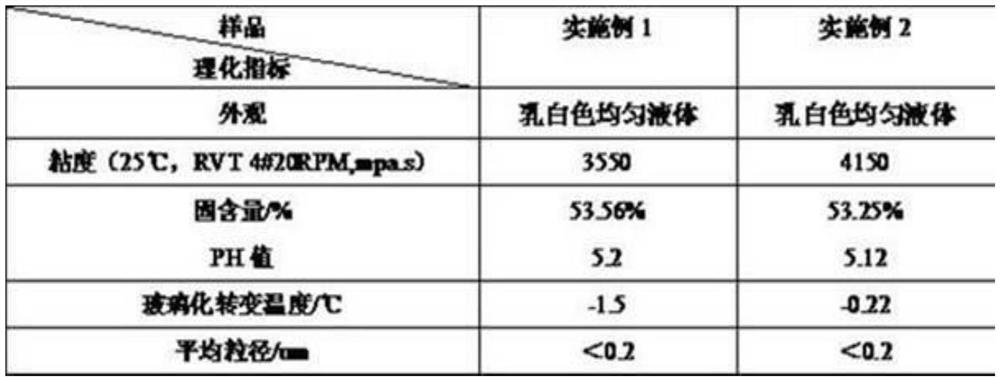

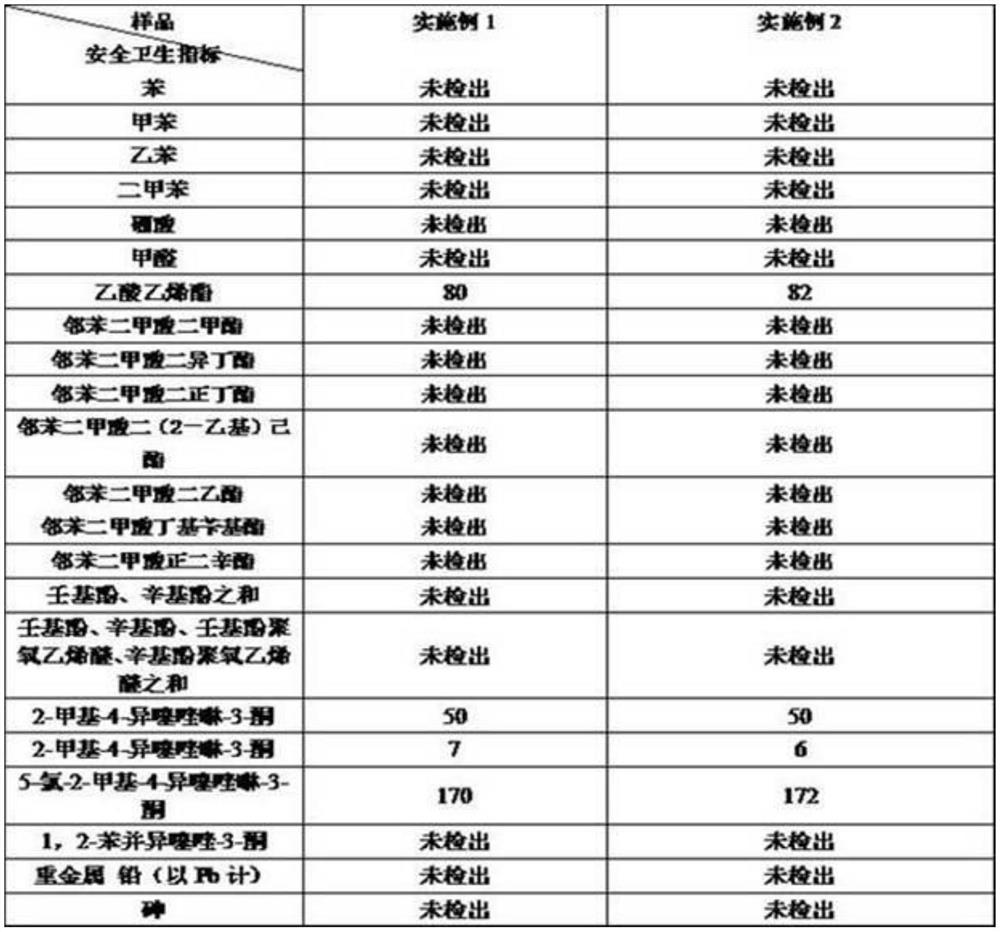

Examples

Embodiment 1

[0026] According to the following methods and steps, prepare the tip glue for anti-permeation tipping paper:

[0027] (1) Prepare 30% polyvinyl alcohol for later use: Quantify first, take 70% pure water into the stirring tank, start stirring, and then slowly add 30% polyvinyl alcohol into the stirring tank , stirred at a speed of 120r / min for 10min to mix polyvinyl alcohol and water evenly, then heated to 90°C, and kept at this temperature for 2h, and finally cooled naturally to room temperature, turned off the stirring, and discharged to obtain polyethylene alcohol solution. The degree of alcoholysis of polyvinyl alcohol is 88%, and the degree of polymerization is 500;

[0028] (2) Add long carbon chain polymerizable fatty acid monomers into pure acrylic emulsion for copolymerization reaction to prepare acrylic emulsion. The indicators of the acrylic emulsion are: glass transition temperature: -18°C, solid content: 50.5%, pH value: 4.55, viscosity: 520mpa.s;

[0029] (3) W...

Embodiment 2

[0033] According to the following methods and steps, prepare the tip glue for anti-permeation tipping paper:

[0034] (1) Prepare 30% polyvinyl alcohol for later use: Quantify first, take 70% pure water into the stirring tank, start stirring, and then slowly add 30% polyvinyl alcohol into the stirring tank , stirred at a speed of 120r / min for 10min to mix polyvinyl alcohol and water evenly, then heated to 90°C, and kept at this temperature for 2h, and finally cooled naturally to room temperature, turned off the stirring, and discharged to obtain polyethylene alcohol solution. The degree of alcoholysis of polyvinyl alcohol is 88%, and the degree of polymerization is 500;

[0035] (2) Add long carbon chain polymerizable fatty acid monomers into pure acrylic emulsion for copolymerization reaction to prepare acrylic emulsion. The indicators of the acrylic emulsion are: glass transition temperature: -18°C, solid content: 50.5%, pH value: 4.55, viscosity: 520mpa.s;

[0036] (3) Wei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com