Electric wire manufacturing method and cable manufacturing method

A manufacturing method and technology of electric wires, applied in the direction of cable/conductor manufacturing, conductor/cable insulation, circuit, etc., can solve problems such as interlayer peeling, poor dispersion, strength drop, etc., and achieve the effect of excellent mechanical properties and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

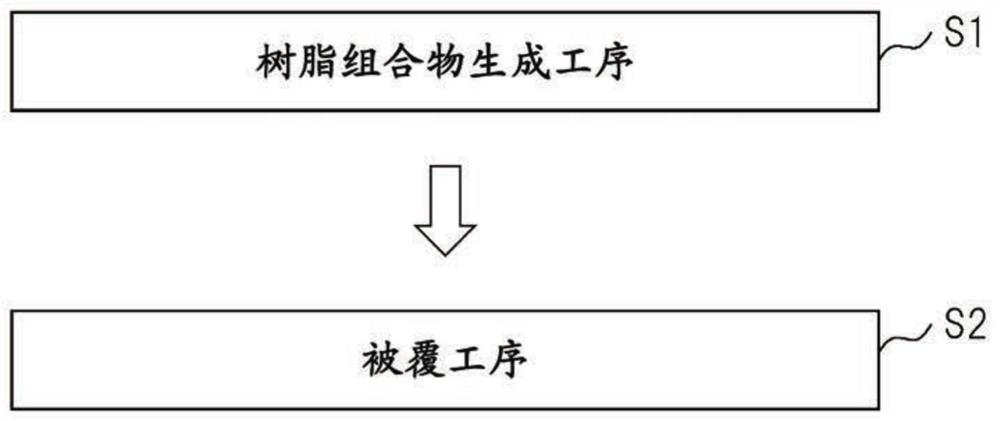

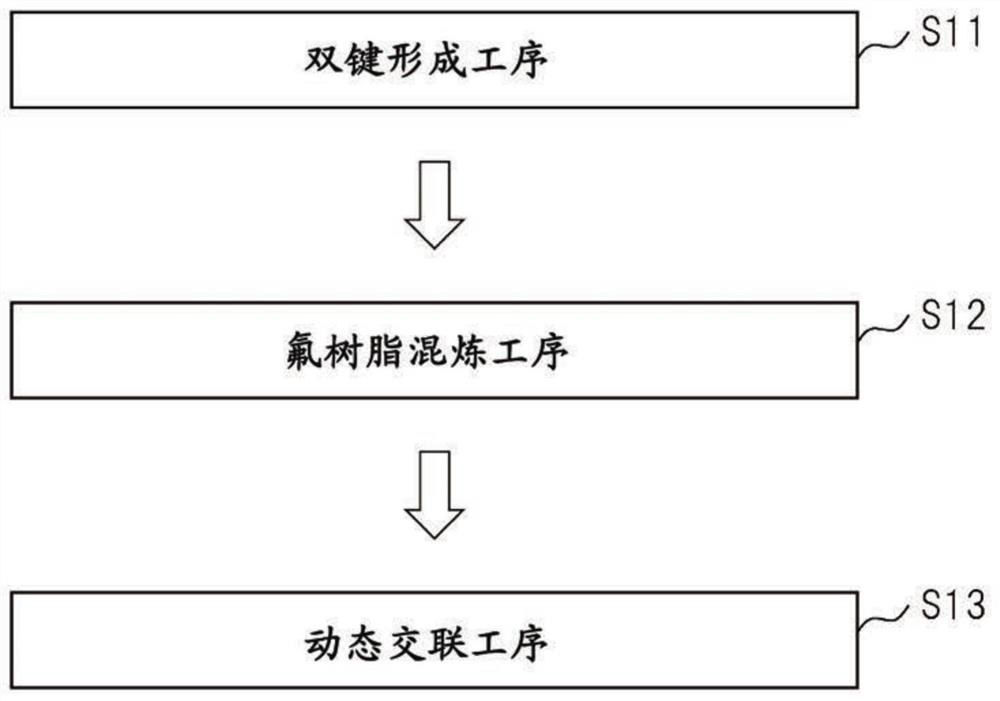

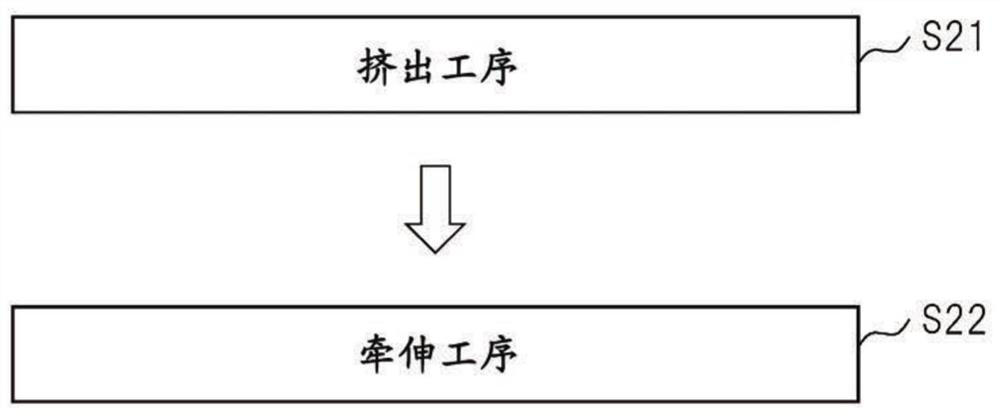

[0055] Hereinafter, the configuration and manufacturing method of an electric wire (insulated electric wire) and a cable according to an embodiment of the present invention will be described. figure 1 To show the flow of the manufacturing process of electric wires and cables according to one embodiment of the present invention; figure 2 for display figure 1 In the flow shown, the flow of the production process of the thermoplastic fluororesin composition; image 3 for display figure 1 In the flow shown, the flow of the coating process of wires and cables. Figure 4 A cross-sectional view showing an electric wire according to an embodiment of the present invention; Figure 5 It is a cross-sectional view showing a cable according to one embodiment of the present invention. Figure 6 A schematic diagram showing an extrusion coating device for manufacturing a wire or cable according to an embodiment of the present invention; Figure 7 for display Figure 6 In the extrusion ...

Embodiment 1

[0157] [Summary of Embodiment 1 and Embodiment 2]

[0158] Example 1 and Example 2 will be described below. Example 1 and Example 2 are electric wires manufactured by the manufacturing method of the present embodiment described above, corresponding to Figure 4 Wire 10 is shown.

Embodiment 2

[0159]

[0160] as Figure 4 Conductor 1 shown, using a cross-sectional area of 2mm 2 nickel-plated stranded conductors. In addition, raw materials constituting the thermoplastic fluororesin composition constituting the insulating layer 2 of Example 1 and Example 2 are as follows.

[0161] (A) Viton rubber: DS246 (hexafluoropropylene / vinylidene fluoride binary copolymer, made in China, specific gravity 1.86, Mooney viscosity 75)

[0162] (B) Fluorine resin:

[0163] (B1) F1540 (copolymer of trifluoro(trifluoromethoxy)ethylene and tetrafluoroethylene, manufactured by Solvay, MFR (melt flow rate) 8 to 18 g / 10 min, melting point 270° C.)

[0164] (B2) M640 (trifluoro(trifluoromethoxy)ethylene and 1,1,1,2,2,3,3-heptafluoro-3-[(trifluorovinyl)oxy]propane with tetrafluoroethylene Copolymer made by Solvay, MFR10~17g / 10min, melting point 285°C)

[0165] (B3) AP-201 (copolymer of trifluoro(trifluoroethoxy)ethylene and tetrafluoroethylene, manufactured by Daikin Industries, MFR...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com