Preparation method of active macromolecular keratin and application thereof as biological dressing

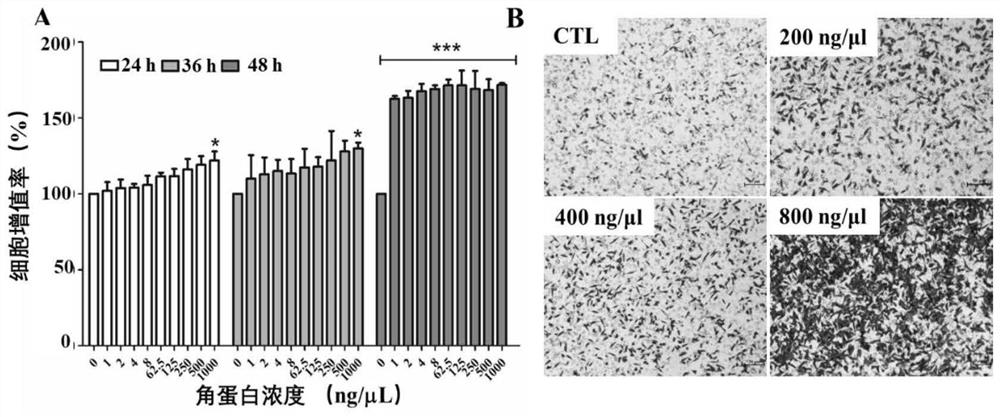

A technology of keratin and macromolecules, which is applied in the field of preparation of active macromolecular keratin, can solve the problems of difficult extraction and reuse of keratin, secondary environmental pollution, toxic reagent residues, etc., and achieve the extraction process of environmental protection, environmental protection, Effects that promote proliferation and migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Wash the wool fiber with deionized water, degrease it in a Soxhlet extractor with acetone 3 times the volume of wool for 24 hours, then wash off the residual acetone on the surface with 40°C deionized water, dry the obtained wool fiber shredded;

[0030] (2) Disperse 5 g of shredded degreased wool in 50 mL of water, adjust the pH value to 9 with 1 mol / L NaOH solution, seal it, raise the temperature to 65 ° C, and mechanically stir for 1 h;

[0031] (3) Lower the temperature to 50°C, add 100KU enzymatic keratinase solution for enzymolysis, and continue to degrade with mechanical stirring for 60 hours;

[0032] (4) centrifuging the mixed solution of wool and keratin obtained in step (3), and separating the supernatant keratin solution;

[0033] (5) Dialyzing the supernatant keratin solution obtained in step (4) for 72 hours;

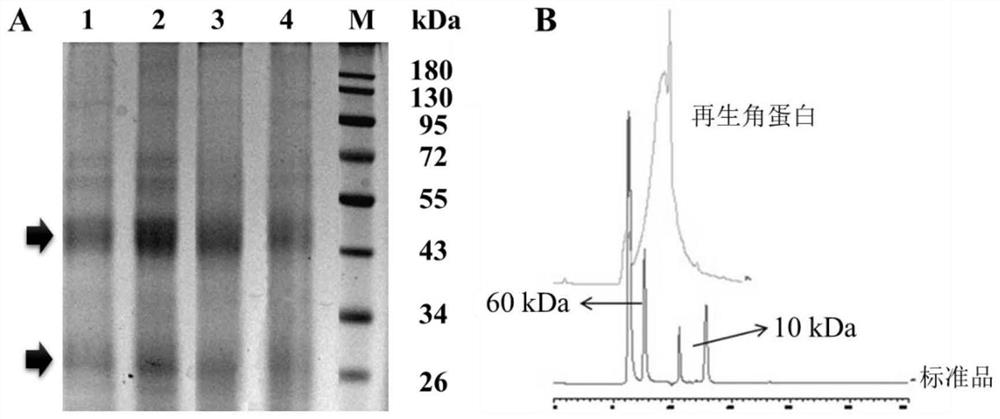

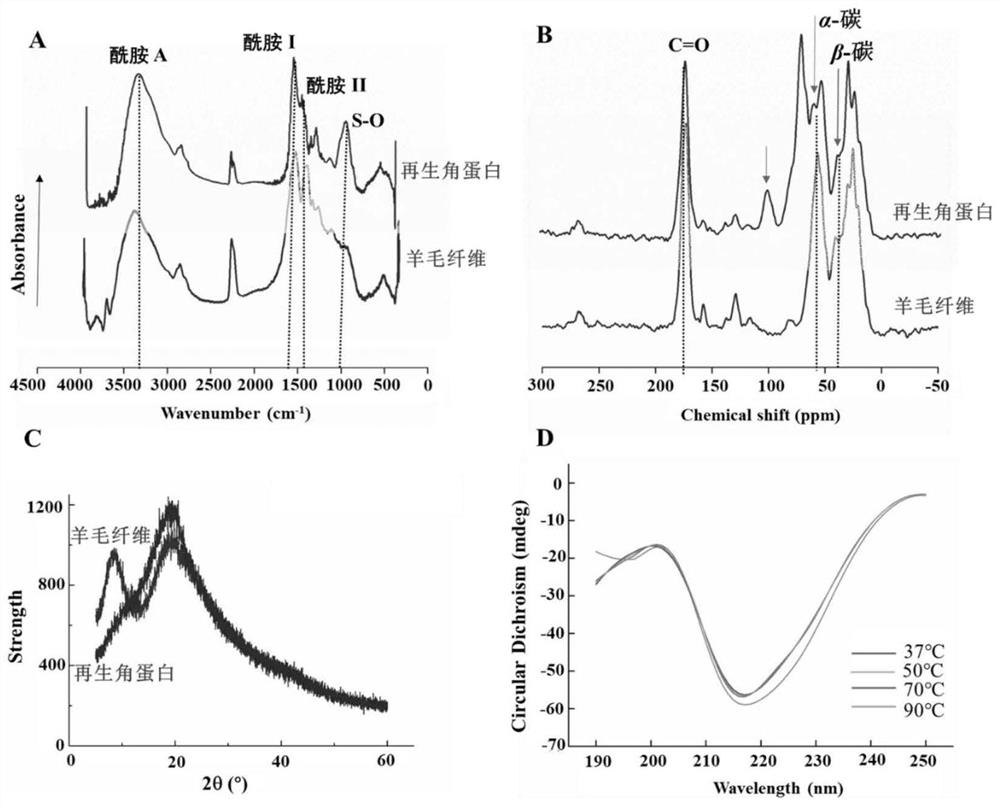

[0034] (6) After the dialysis is completed, the dialysate was frozen at -80°C for 6 hours, and then dried on a freeze dryer for 72 hours to o...

Embodiment 2

[0036] (1) Wash the wool fiber with deionized water, degrease the wool fiber with 4 times the volume of wool in a Soxhlet extractor for 24 hours, then wash off the residual acetone on the surface with 50°C deionized water, dry the obtained wool fiber shredded;

[0037] (2) Disperse 5 g of shredded degreased wool in 100 mL of water, adjust the pH value to 10 with 1 mol / L NaOH solution, seal it, raise the temperature to 70 ° C, and stir it mechanically for 1 h;

[0038] (3) Lower the temperature to 50°C, add 150KU enzymatic keratinase solution for enzymolysis, and continue mechanical stirring for 54 hours to degrade;

[0039] (4) centrifuging the mixed solution of wool and keratin obtained in step (3), and separating the supernatant keratin solution;

[0040] (5) Dialyzing the supernatant keratin solution obtained in step (4) for 72 hours;

[0041] (6) After the dialysis is completed, the dialysate is frozen at -80°C for 8 hours, and then dried on a freeze dryer for 48 hours t...

Embodiment 3

[0043] (1) Wash the wool fiber with deionized water, degrease the wool fiber with 5 times the volume of wool in a Soxhlet extractor for 12 hours, then wash off the residual acetone on the surface with 50°C deionized water, dry the obtained wool fiber shredded;

[0044] (2) Disperse 5 g of shredded degreased wool in 150 mL of water, adjust the pH value to 11 with 1 mol / L NaOH solution, seal it, raise the temperature to 85 ° C, and mechanically stir for 1 h;

[0045] (3) Lower the temperature to 50°C, add 200KU enzymatic keratinase solution for enzymolysis, and continue mechanical stirring for 48 hours;

[0046] (4) centrifuging the mixed solution of wool and keratin obtained in step (3), and separating the supernatant keratin solution;

[0047] (5) Dialyzing the supernatant keratin solution obtained in step (4) for 72 hours;

[0048] (6) After the dialysis is completed, the dialysate is frozen at -80°C for 12 hours, and then dried on a freeze dryer for 48 hours to obtain soli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com