Polymer modifier for concrete, preparation method thereof, and impermeable and waterproof concrete

An anti-seepage and waterproof concrete technology, applied in the field of composite materials, can solve the problems of poor concrete anti-seepage and water resistance, cement particle aggregation, incomplete cement hydration, etc., to avoid incomplete hydration, reduce interfacial tension, and improve anti-seepage. Osmotic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

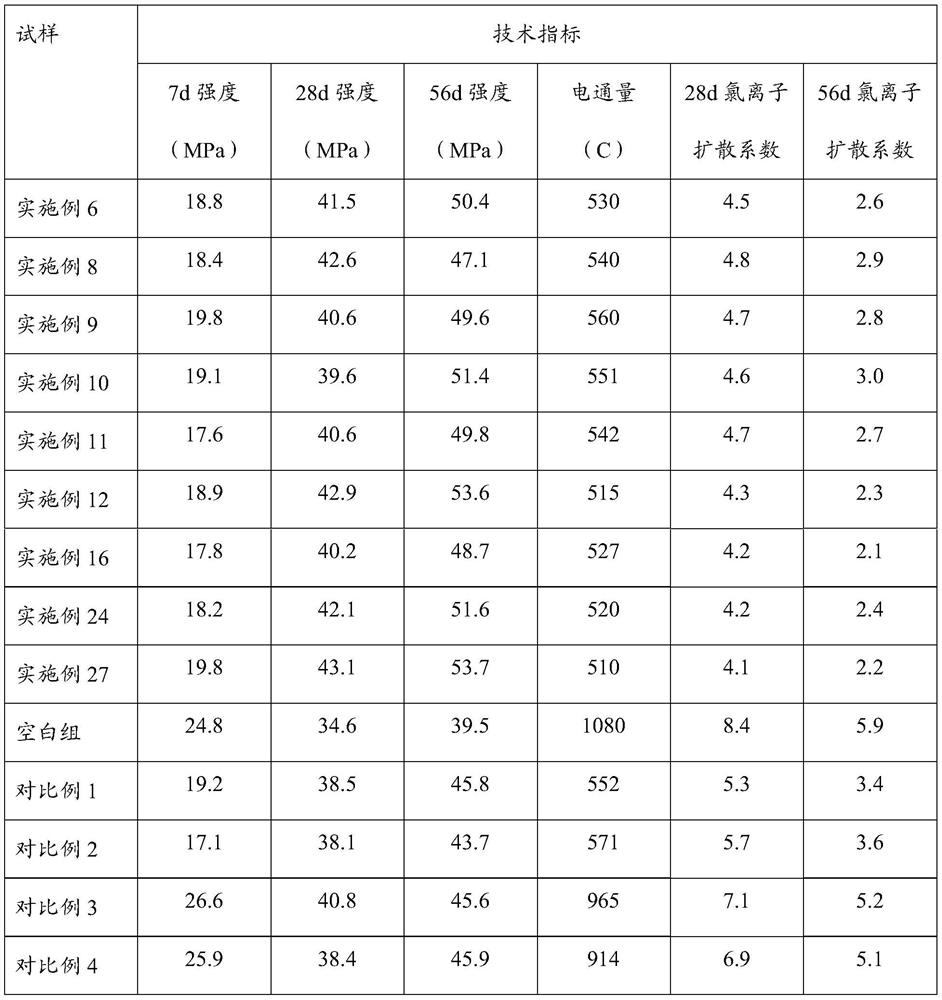

Examples

preparation example Construction

[0020] The invention provides a kind of preparation method of polymer modifier for concrete, comprising the following steps:

[0021] S1 weighs polymer emulsion, silica sol and silane coupling agent by weight ratio;

[0022] S2 Mix the silica sol, silane coupling agent and polymer emulsion, and then conduct ultrasonic treatment to obtain a mixed liquid. The ultrasonic conditions are: ultrasonic time 3min-10min, ultrasonic at room temperature.

[0023] The invention provides an anti-seepage and waterproof concrete, which comprises the following components by weight: 230-360 parts of cement, 60-100 parts of fly ash, 28-50 parts of expansion agent, 650-820 parts of fine powder Aggregate, 950-1100 parts of coarse aggregate, 4.35-5.85 parts of water reducing agent, 100-150 parts of water, 0.85-1.35 parts of defoamer and 40-80 parts of polymer modifier. The anti-seepage and waterproof concrete prepared by the invention has good anti-seepage and waterproof effect, thereby effectivel...

Embodiment 1

[0033]A polymer modifier for concrete, comprising a polymer emulsion and an interfacial modifier, the interfacial modifier comprising silica sol and a silane coupling agent; the addition amount of the polymer emulsion and the interfacial modifier is 1:0.2 . The polymer emulsion is styrene-acrylic emulsion.

[0034] Its preparation method is,

[0035] S1 weighs polymer emulsion, silica sol and silane coupling agent by weight ratio;

[0036] S2 mixes the silica sol, silane coupling agent and polymer emulsion to obtain a mixed solution through ultrasonic treatment. The ultrasonic conditions are as follows: the ultrasonic time is 5 minutes, and the ultrasonic is carried out at room temperature.

Embodiment 2

[0038] The difference between this example and Example 1 is that the addition amount of the polymer emulsion and the interface modifier is 1:0.4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com