Novel foam generator capable of preparing stable and size-controllable foam

A foam generator and foam technology, applied in fluid mixers, chemical instruments and methods, transportation and packaging, etc., can solve problems such as weight loss and strength retention, poor foam stability, and difficult size control, and achieve strength High, low unit weight, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the purpose, technical solution and advantages of the application clearer, the embodiments of the application will be described in detail below in conjunction with the accompanying drawings. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined arbitrarily with each other.

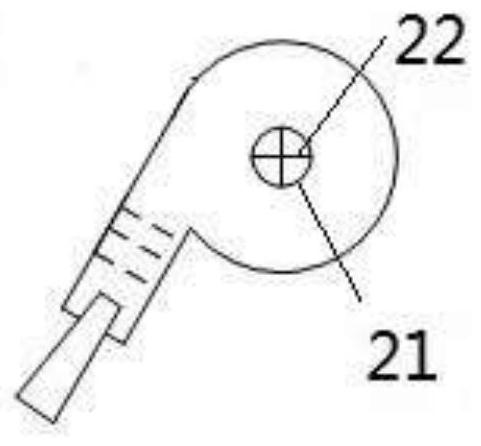

[0026] The embodiment of the present application provides a novel foam generator capable of producing stable and size-controllable foam, such as figure 1 As shown, it includes: a mixing device 1 , a foam screening stabilization device 2 and a liquid collector 3 .

[0027] The inlet of the mixing device 1 is configured to be connected to the air compressor 100 and the foaming agent dilution liquid storage tank 200 respectively through pipelines;

[0028] A foam sieving stabilization device 2, the inlet of the foam sieving stabilization device 2 is connected to the outlet of the mixing devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com