Energy storage management method and system for oil pumping machine, and electronic equipment

A management method and technology for a management system, which are applied in the fields of systems and electronic equipment, and energy storage management methods for oil pumping units, can solve problems such as grid pollution, low power factor, and impact on electrical equipment, and achieve improved equipment power factor. Low power loss and improved safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

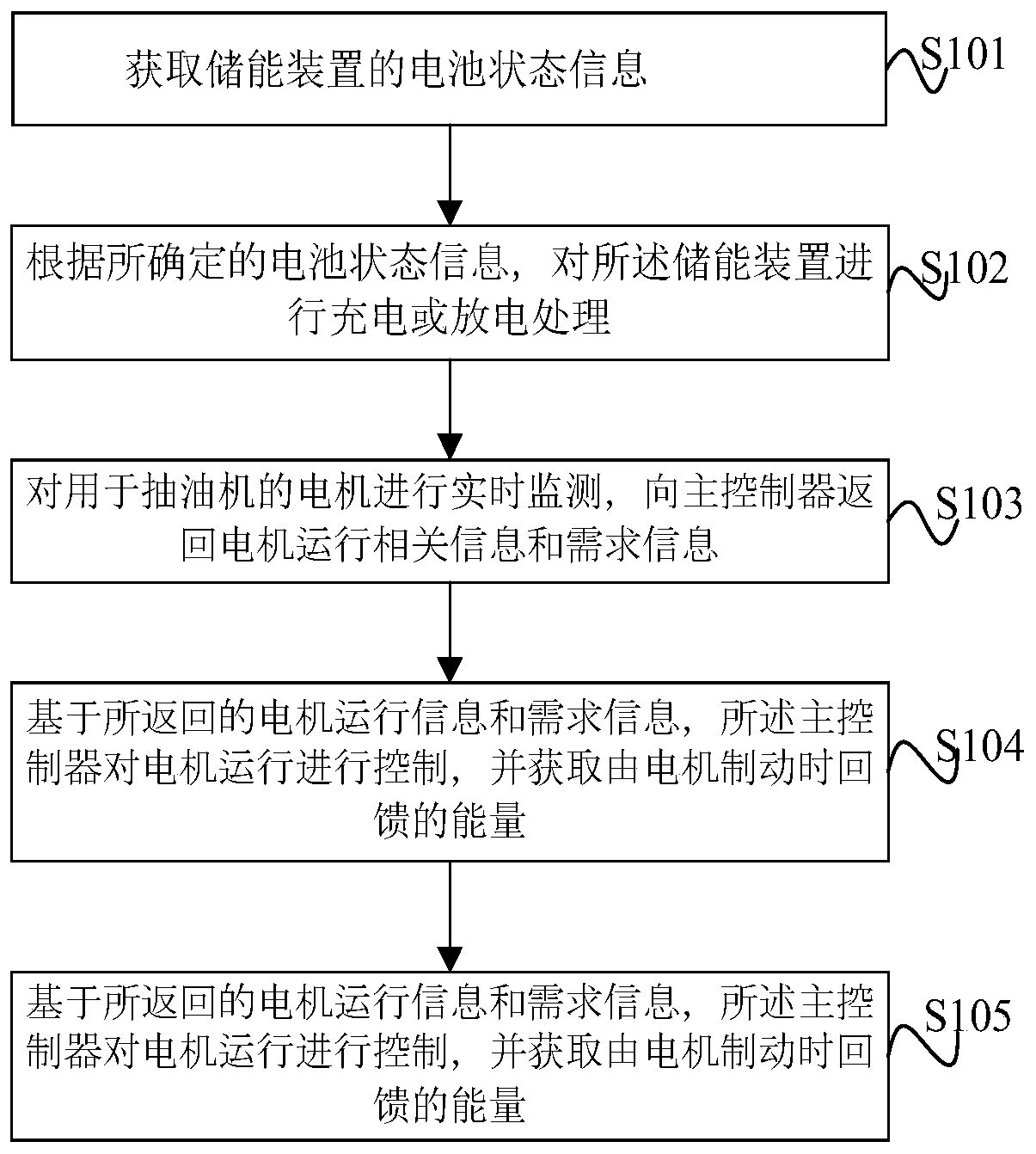

[0029] The following will refer to Figure 1 to Figure 5 An embodiment of a method of energy storage management for a pumping unit is described.

[0030] figure 1 It is a schematic flowchart of an example of the energy storage management method for pumping units of the present invention.

[0031] Such as figure 1 Shown, a kind of energy storage management method for pumping unit, described method comprises:

[0032] Step S101, acquiring battery status information of an energy storage device.

[0033] Step S102 , charging or discharging the energy storage device according to the determined battery state information.

[0034] In step S103, real-time monitoring is performed on the motor used for the pumping unit, and information related to motor operation and demand information is returned to the main controller.

[0035] Step S104, based on the returned motor operation information and demand information, the main controller controls the operation of the motor, and obtains t...

Embodiment 2

[0071] refer to Figure 6 , the energy storage management system for pumping units of the present invention will be described, and the energy storage management system performs energy storage management through the energy storage management method described in Embodiment 1.

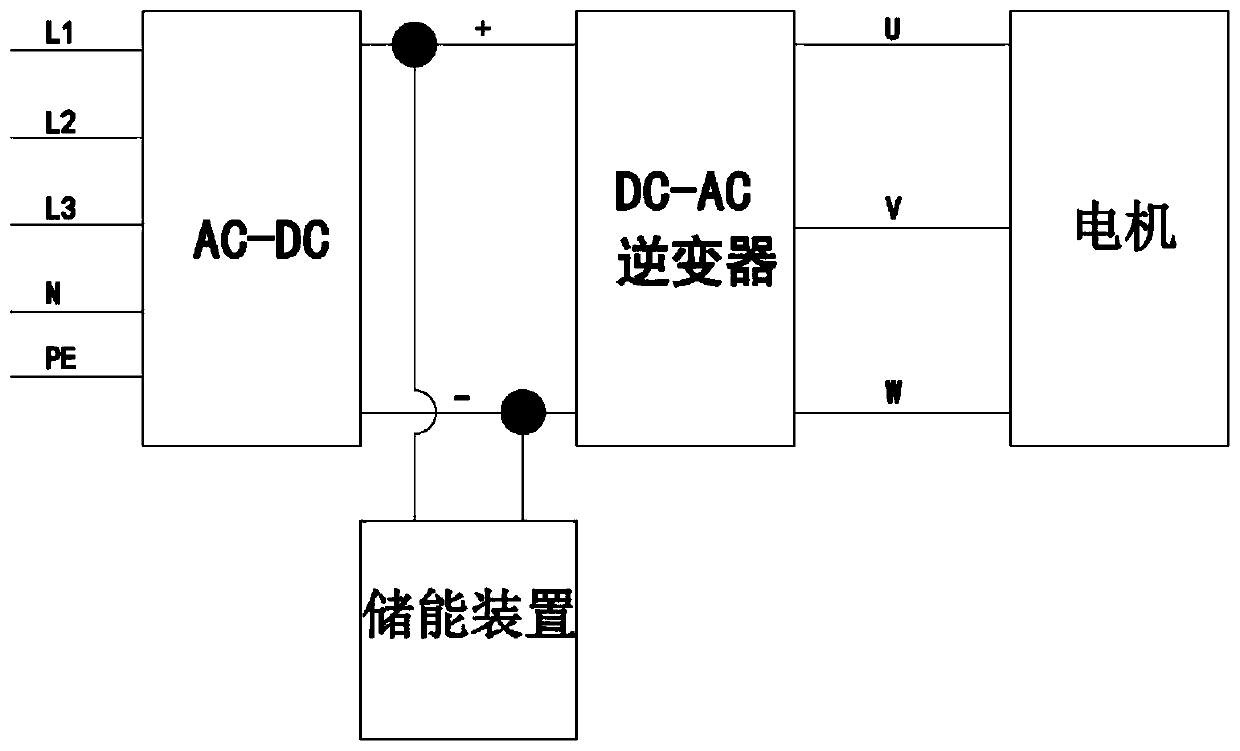

[0072] Such as Figure 6 As shown, an energy storage management system 600 based on a pumping unit, the energy storage management system 600 includes: an energy storage device 601, including a nickel-metal hydride battery pack and / or a lithium-ion battery pack, and each battery pack is equipped with a battery An energy management device, the battery energy management device is used to collect battery status information; a power motor 602, which is used for a pumping unit; a motor controller 603, which is electrically connected to the power motor 602; a controllable ACDC module 604, which It is electrically connected with the energy storage device 601 and the motor controller 603 , and is used for inputti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com