A preparation method of titanium oxide nanotube array-based photoelectrochemical detection electrode

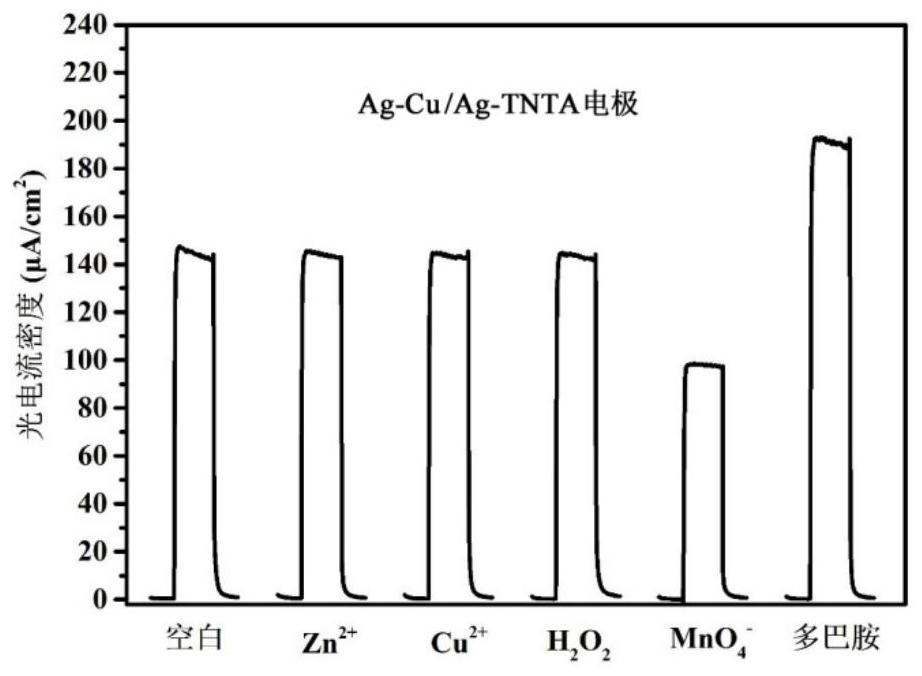

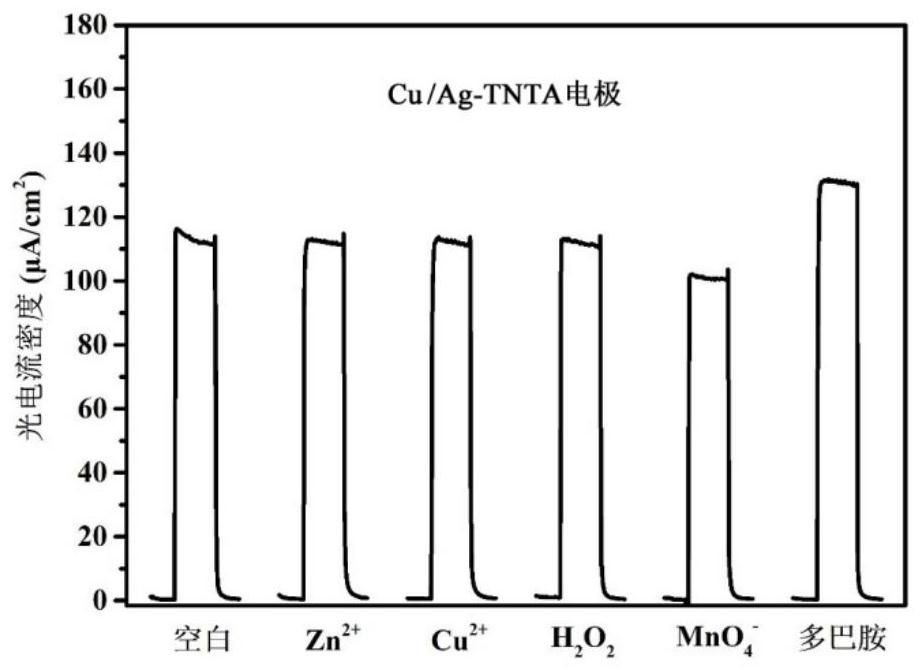

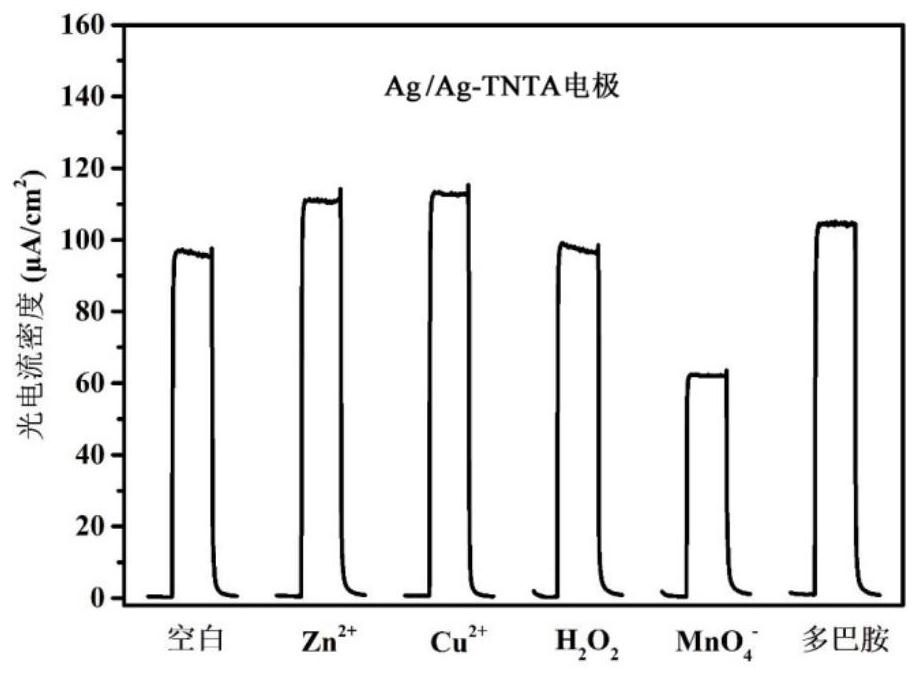

A titanium oxide nanotube and photoelectrochemical technology, applied in the field of analysis and detection, can solve the problems of easy agglomeration of active substances, poor conductivity, and high detection cost, and achieve the effects of reducing interfacial tension, fine metal particles, and increasing the number of hydroxyl groups.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Ultrasonic cleaning of the Ti sheet (10 mm×20 mm×0.3 mm) with ethanol and distilled water to remove oil stains on the surface of the Ti sheet. Use 0.15g ammonium fluoride, 5g distilled water and 45g ethylene glycol to prepare a mixed solution, insert 10mm of the lower end of the Ti sheet into the mixed solution, the Ti sheet is the anode, and the Pt sheet is used as the cathode. Anodized for 3 hours under the conditions, a titanium dioxide nanotube array film (marked as TNTA) was formed on the surface of the metal titanium sheet; after the reaction, the sample was washed with distilled water and dried.

[0035] (2) A 0.03M silver nitrate solution containing 0.05M nitric acid and 0.05M ethanolamine was prepared. The TNTA was first soaked in 10ml silver nitrate solution for 10min, then the excess solution on the surface of the sample was washed with distilled water, and then soaked in 10ml 0.1M NaOH solution for 10min, and finally the sample was soaked in distilled wa...

Embodiment 2

[0045] (1) An electrolyte was prepared with 0.1 g of ammonium fluoride, 7.5 g of distilled water and 42.5 g of ethylene glycol. The process steps were the same as those in Example 1 (1), and anodic oxidation was carried out at 35° C. and 45 V for 2 hours to prepare TNTA.

[0046] (2) Prepare a 0.05M silver nitrate solution containing 0.1M nitric acid and 0.1M ethanolamine, the process steps are the same as those in Example 1(2), and Ag-TNTA is prepared by co-deposition twice.

[0047] (3) A copper-silver ion mixed solution containing 0.01M nitric acid, 0.01M ethanolamine, 0.005M silver nitrate and 0.045M copper nitrate was prepared.

[0048] Add 0.5 g of hydrazine hydrate to 100 ml of 0.5 M NaOH solution, stir to dissolve, and prepare a reducing solution. The Ag-Cu / Ag-TNTA electrode can be obtained by performing the hydrothermal reduction reaction according to the process conditions of Example 1(3).

Embodiment 3

[0050] (1) An electrolyte was prepared with 0.2 g of ammonium fluoride, 2.5 g of distilled water and 47.5 g of ethylene glycol. The process steps were the same as those in Example 1 (1), and anodic oxidation was carried out at 45° C. and 35 V for 4 hours to prepare TNTA.

[0051] (2) Prepare a 0.01M silver nitrate solution containing 0.01M nitric acid and 0.01M ethanolamine, the process steps are the same as those in Example 1(2), and Ag-TNTA is prepared by co-deposition 9 times.

[0052] (3) Prepare a copper-silver ion mixed solution containing 0.1M nitric acid, 0.1M ethanolamine, 0.09M silver nitrate and 0.01M copper nitrate.

[0053] Add 0.1 g of formaldehyde to 100 ml of 0.1 M NaOH solution, stir to dissolve, and prepare a reducing solution. The Ag-Cu / Ag-TNTA electrode can be obtained by performing the hydrothermal reduction reaction according to the process conditions of Example 1(3).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com