Gas-liquid mixed injection device used for thickened oil double injecting and thin extracting

A gas-liquid and mixed-injection technology, which is used in the development of fluids, petroleum industry, earth-moving drilling, etc., can solve the problems of difficult extraction, high viscosity, and large intermolecular force, and achieves the advantages of oil pumping and oil transportation, and physical fluidity. The effect of strengthening and improving the work effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

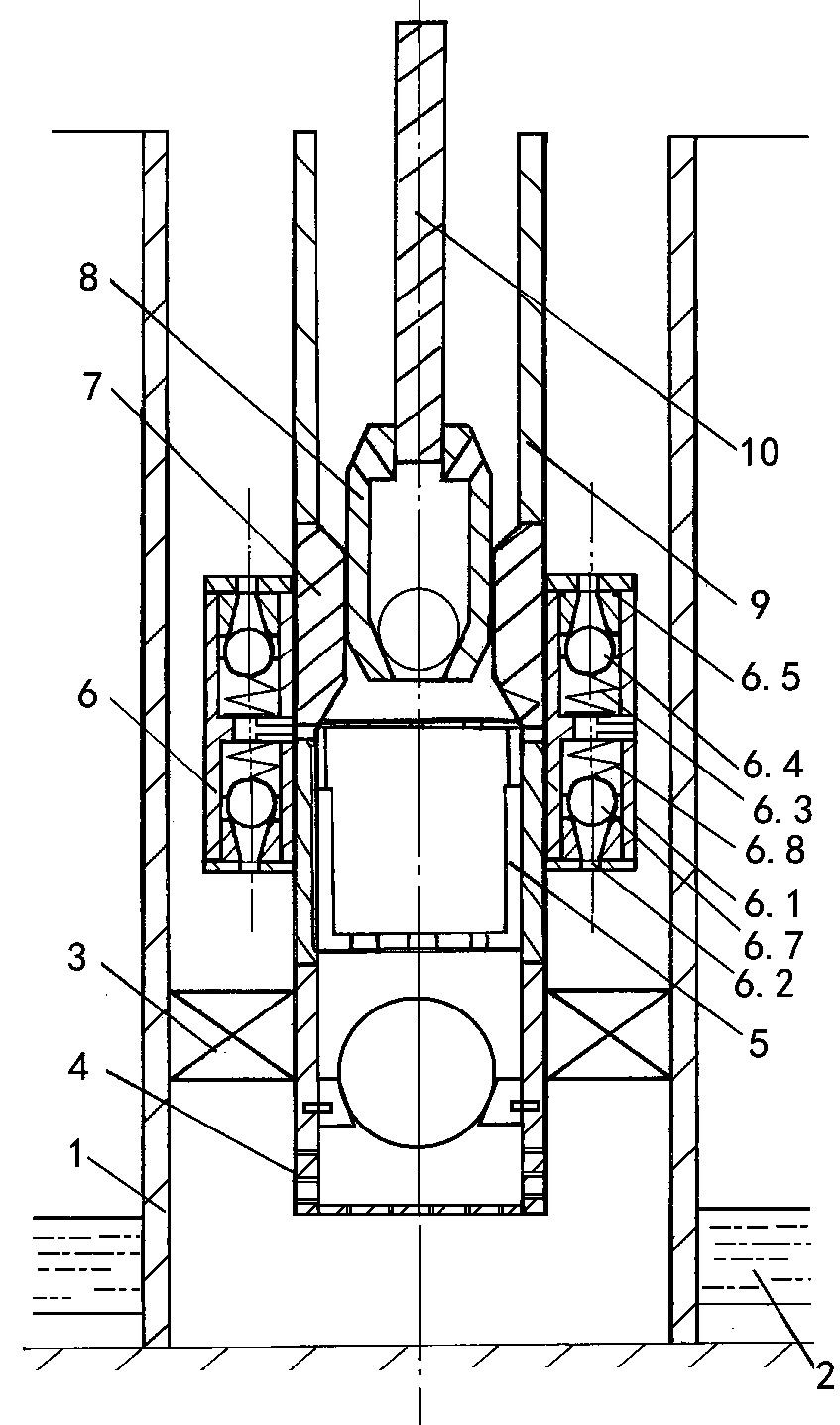

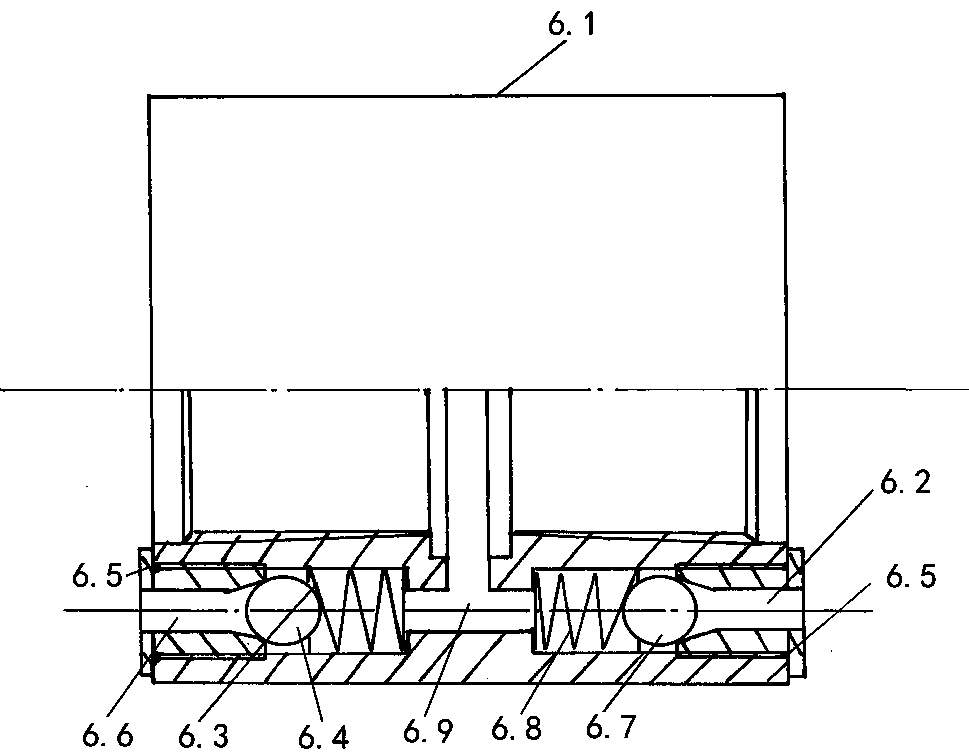

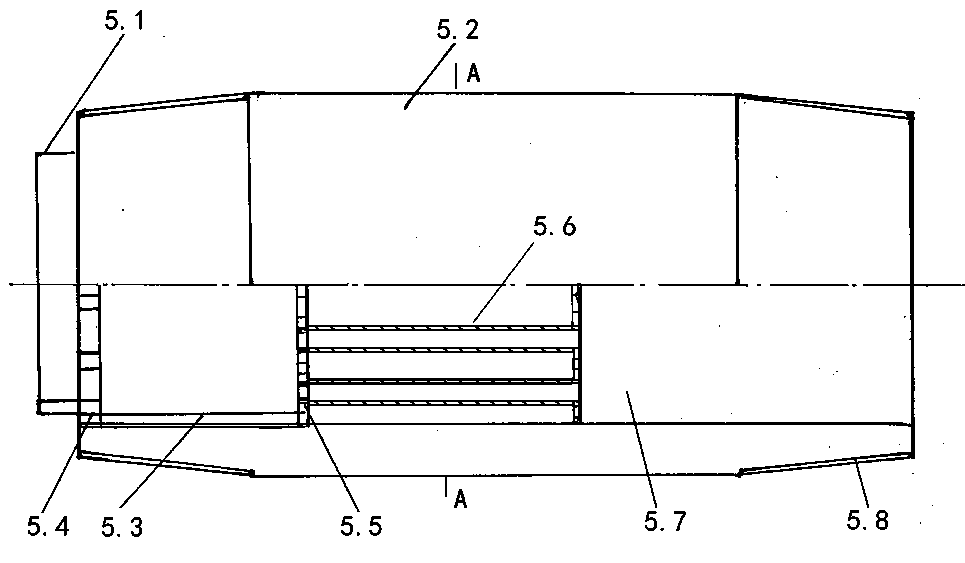

[0033] Example 1, a gas-liquid mixed injection device for double injection of heavy oil mentioned in the present invention, including a double-head liquid injector (6) and a gas-liquid mixed injector (5), and the double-head liquid injector (6) includes Injector body (6.1), injector injection port (6.2), support spring (6.3), sealing steel ball (6.4), sealing rubber ring (6.5), the injector body (6.1) is an annular sleeve The upper surface of the injector body (6.1) is provided with multiple upper injector liquid injection channels (6.6), and the lower surface of the injector body (6.1) is provided with multiple lower injector liquid injection channels (6.2), the inner cavity of the liquid injection channel (6.6) of the upper liquid injector is provided with an upper sealing steel ball (6.4) and an upper support spring (6.3), and the inner cavity of the liquid injection channel (6.2) of the lower liquid injector is provided with There is a lower sealing steel ball (6.7) and a ...

Embodiment 2

[0065] Example 2, another double-injection of heavy oil mentioned in the present invention uses a gas-liquid mixed injection device, and its technical solution is: including a double-headed liquid injector (6) and a gas-liquid mixed injector (5), The liquid device (6) includes the liquid injector body (6.1), the liquid injector injection port (6.2), the support spring (6.3), the sealing steel ball (6.4), the sealing rubber ring (6.5), and the liquid injector body ( 6.1) is an annular sleeve structure, with multiple upper injector liquid injection channels (6.6) on the upper surface of the injector body (6.1), and multiple lower injector channels (6.6) on the lower surface of the injector body (6.1). The injection channel (6.2) of the injector, the inner cavity of the injection channel (6.6) of the upper injector is provided with an upper sealing steel ball (6.4) and an upper support spring (6.3), and the injection channel of the lower injector ( The inner cavity of 6.2) is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com