A heavy oil double-injection thin recovery device

A heavy oil, injection-production tubing string technology, applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc., can solve the problems of large intermolecular force, difficulty in production, and high freezing point, and achieves improved stability and is beneficial to The effect of oil pumping and oil transportation, physical fluidity enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

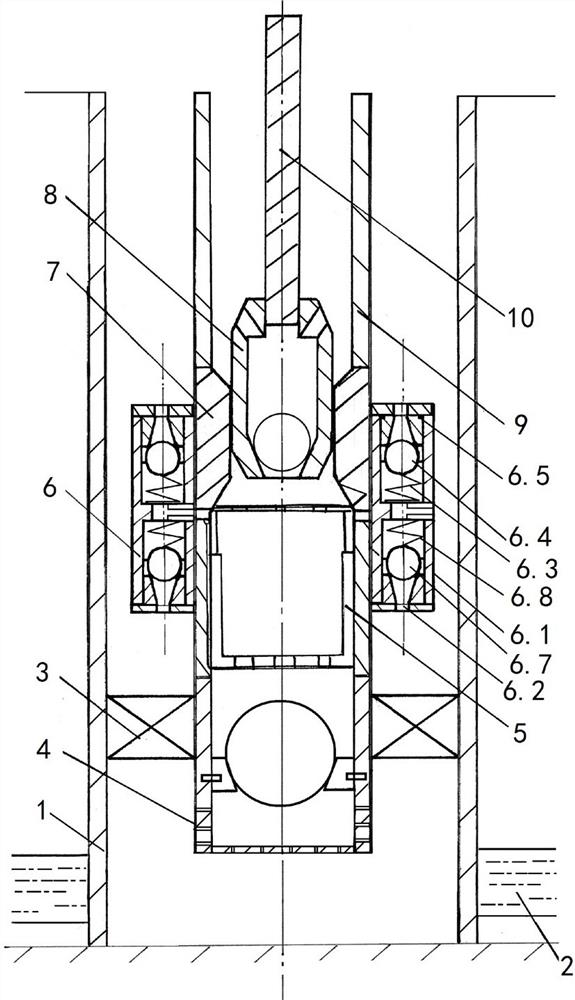

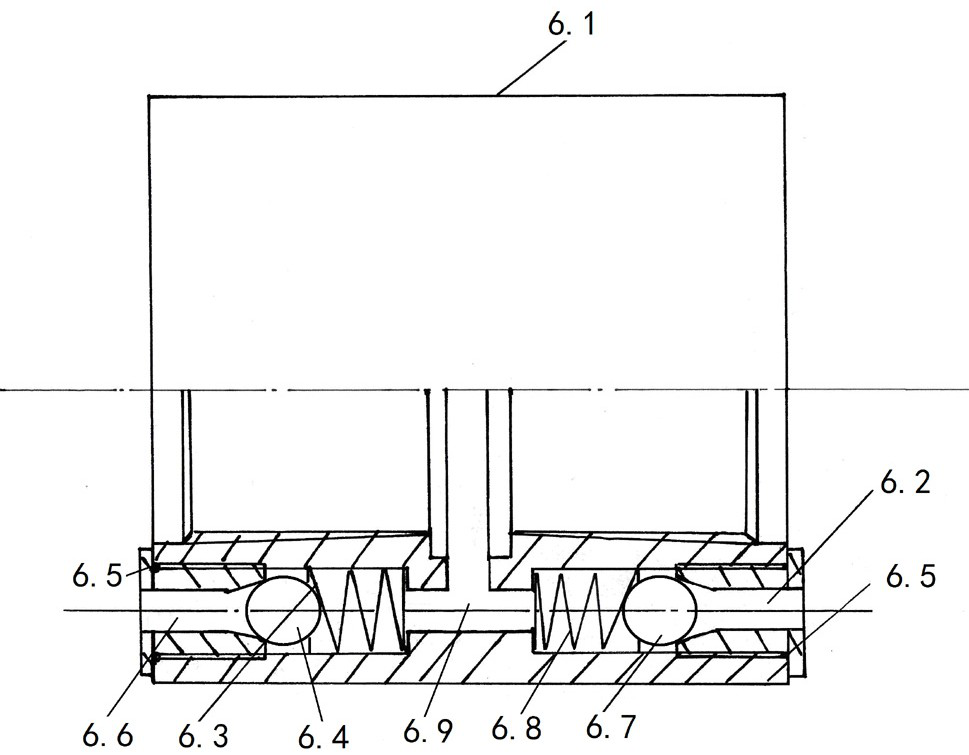

[0038] Embodiment 1, with reference to attached Figure 1-4 And 6-7, a kind of double-injection thin recovery device for heavy oil mentioned in the present invention, the inner cavity of oil well casing 1 is provided with injection-production pipe string 9, is provided with sucker rod 10 in the injection-production pipe string 9, and oil pumping The bottom of the rod 10 is provided with an oil well pump plunger 8, and the bottom of the oil well casing 1 is provided with an oil well pump barrel 7, and the oil well pump plunger 8 cooperates with the oil well pump barrel 7 to realize fluid extraction, and the bottom of the oil well pump barrel 7 is connected to The gas-liquid mixed injector 5 is provided with a pump tailpipe 4 at the bottom of the gas-liquid mixed injector 5, and the outer wall of the oil pump barrel 7 and the gas-liquid mixed injector 5 is provided with a double-headed liquid injector 6. A high-temperature packer 3 is provided between the outer wall of the lower...

Embodiment 2

[0067] Embodiment 2, a heavy oil double-injection thin production device mentioned in the present invention, the inner cavity of the oil well casing 1 is provided with an injection-production string 9, and a sucker rod 10 is arranged in the injection-production string 9, and the sucker rod The bottom of 10 is provided with oil well pump plunger 8, and the bottom of oil well casing 1 is provided with oil well pump barrel 7, and oil well pump plunger 8 cooperates with oil well pump barrel 7 to realize liquid extraction, and the bottom of described oil well pump barrel 7 is connected to gas The liquid mixed injector 5 is provided with a pump lower tailpipe 4 at the bottom of the gas-liquid mixed injector 5, and the outer wall of the oil pump barrel 7 and the gas-liquid mixed injector 5 is provided with a double-headed liquid injector 6, and the pump lower A high-temperature packer 3 is provided between the outer wall of the liner 4 and the oil well casing 1; the double-head liquid...

Embodiment 3

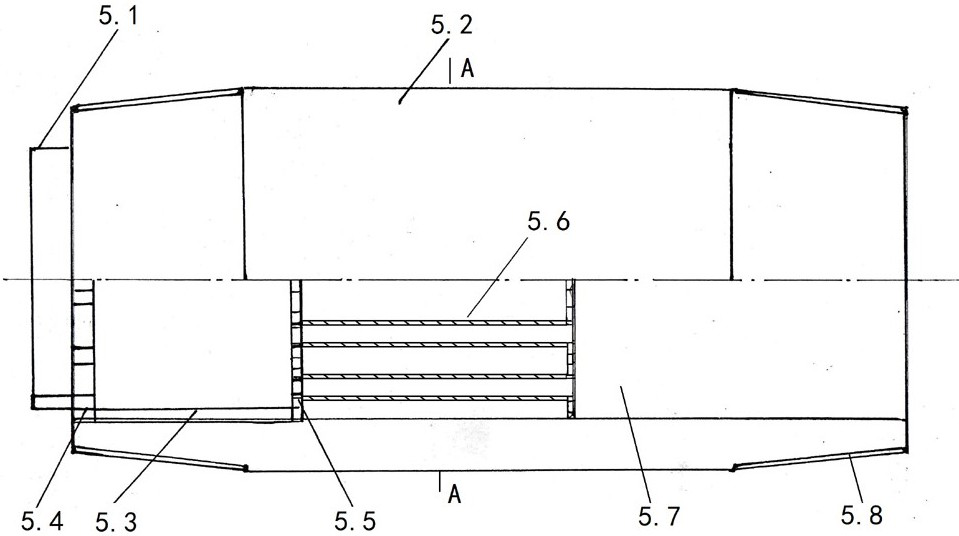

[0073] Embodiment 3, difference with embodiment 1 and 2 is: with reference to appended Figure 5 , the gas-liquid mixed injector 5 adopted in the present invention includes a liquid inlet slotted pipe 5.1, a carrier 5.2, a gas-liquid homogenizing chamber 5.3, a gas deflector 5.4, a gas-liquid homogenizing plate 5.5, a multi-stage capillary 5.6, and a lower chamber of the mixed injector Body 5.7, lower joint 5.8, cavity 5.9 of the mixer, one end of the liquid inlet slotted pipe 5.1 is connected to the bottom of the oil pump barrel 7, and the side wall of the liquid inlet slotted pipe 5.1 is connected to the double-headed liquid injector 6 The liquid outlet channel 6.9 is connected, and the other end of the liquid inlet slotted pipe 5.1 is provided with a circular gas deflector 5.4, and a gas-liquid homogenization chamber is formed between the gas deflector 5.4 and the gas-liquid homogenization plate 5.5 5.3, under the gas-liquid homogenizing plate 5.5, a multi-stage capillary 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com