Oil pumping rod guiding device

A technology of guiding device and sucker rod, which is applied in the direction of drill pipe, drilling equipment, earthwork drilling and production, etc. It can solve the problems of shortening the service life of the oil pipe, large rotation resistance of the guider, and wear of the oil pipe in the well, so as to avoid energy loss and facilitate The effect of deviation correction and length shortening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

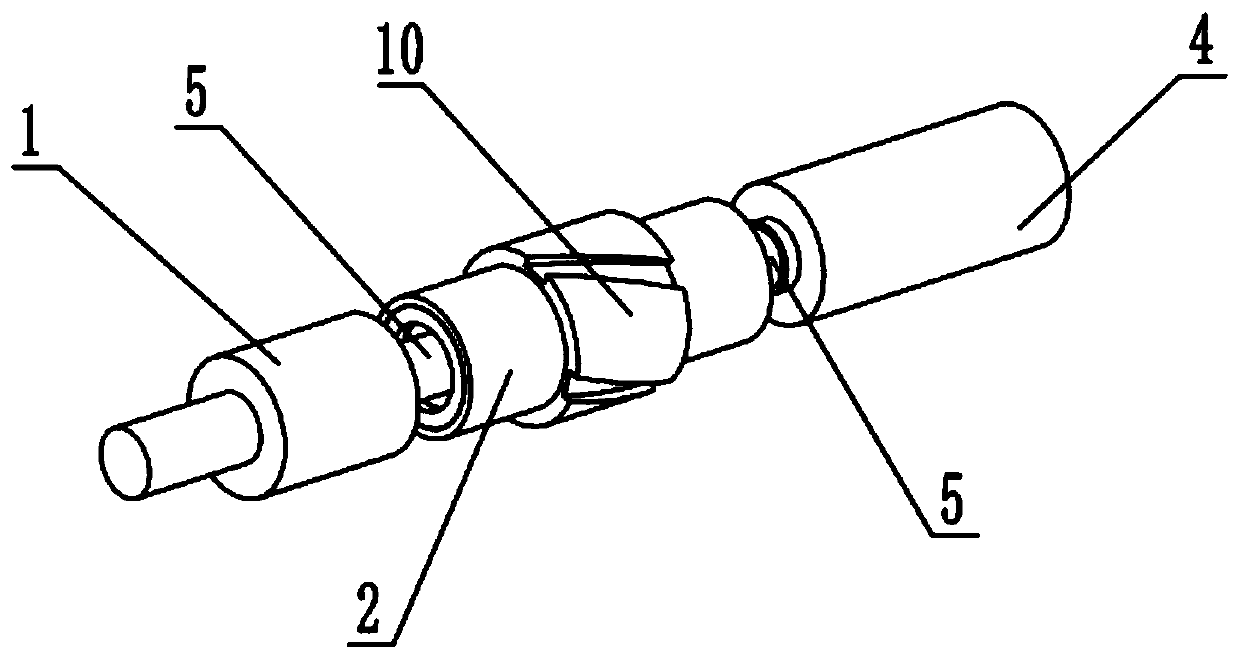

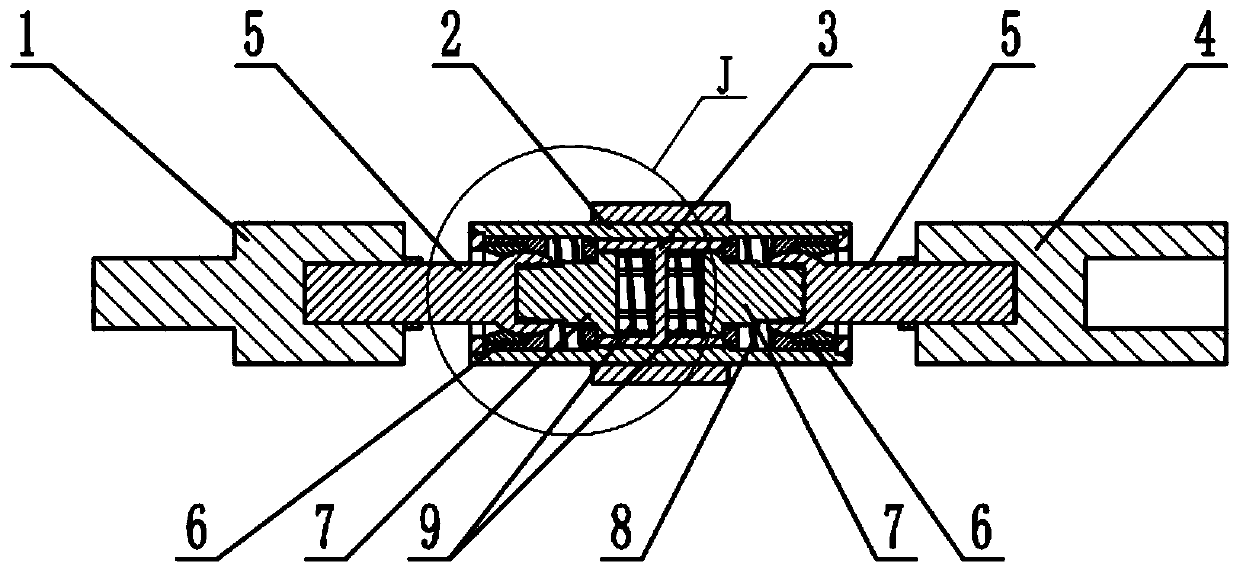

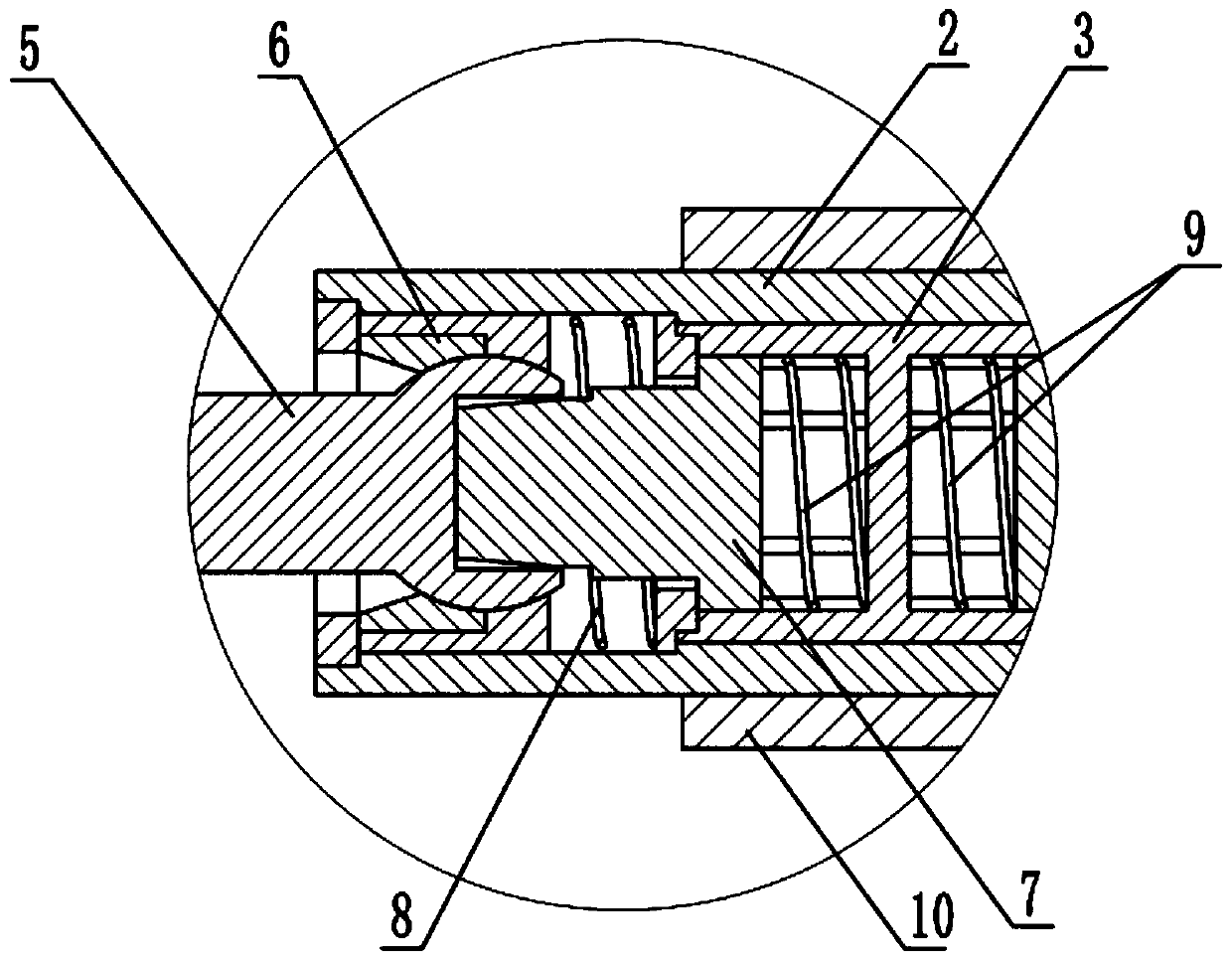

[0027] Such as Figure 1-9 As shown, a sucker rod guide device includes an outer connecting head I1, an outer sleeve 2, an inner rotating sleeve 3, an outer connecting head II4, a connecting shaft 5, a connecting shaft mounting sleeve 6, a transmission shaft 7, a spring I8, a spring II9 and The centralizer 10, the inner rotating sleeve 3 is rotatably connected to the middle inside the outer sleeve 2, the centralizer 10 is fixedly connected to the middle outside the outer sleeve 2, and both ends of the inner rotating sleeve 3 are slidably connected with transmission Shaft 7, the spring II 9 is provided with two, the two springs II 9 are respectively arranged at both ends of the inner rotating sleeve 3, the outer ends of the two springs II 9 are both pressed against the transmission shaft 7, the connecting shaft mounting sleeve 6 is provided with two, two connecting shaft mounting sleeves 6 are respectively slidably connected to the two ends of the outer casing 2, the said spring...

specific Embodiment approach 2

[0030] Such as Figure 1-9 As shown, the jacket 2 includes an outer connecting sleeve 2-1, a jacket stop ring 2-2, and a fixing sleeve 2-3. The fixing sleeve 2-3 is fixedly connected to the middle of the outer connecting sleeve 2-1, and the jacket stop ring 2 -2 is provided with two, the two outer casing stop rings 2-2 are respectively fixedly connected to the two ends of the outer connecting sleeve 2-1, and the centralizer 10 is fixedly connected to the middle part of the outer connecting sleeve 2-1;

[0031] The fixing sleeve 2-3 is used for the rotational installation of the inner rotating sleeve 3, and the outer sleeve retaining ring 2-2 is screwed on both ends of the outer connecting sleeve 2-1 for blocking the connecting shaft installation sleeve 6.

specific Embodiment approach 3

[0033] Such as Figure 1-9 As shown, the inner rotating sleeve 3 includes a rotating inner sleeve 3-1, a keyway 3-2, a middle partition 3-3, and a side baffle ring 3-4. The rotating inner sleeve 3-1 is rotatably connected to the fixed sleeve 2- In 3, the inner wall of the rotating inner sleeve 3-1 is evenly provided with a plurality of key grooves 3-2, the middle part of the rotating inner sleeve 3-1 is fixedly connected with the intermediate partition 3-3, and the side baffle ring 3-4 is provided with two , The two side baffle rings 3-4 are respectively fixedly connected to the two ends of the rotating inner sleeve 3-1, and the outer ends of the two side baffle rings 3-4 are both rotatably connected with the inner wall of the outer connecting sleeve 2-1. The above-mentioned springs I8 are respectively arranged at the two ends of the outer connecting sleeve 2-1, the inner parts of the two springs I8 tighten the two side baffle rings 3-4, and the two springs II9 are respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com