Preparation method of all-cotton fabric fluorine-silicone waterproof finishing agent

A technology for water-repellent finishing, cotton fabrics, used in fiber processing, plant fibers, textiles, and papermaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

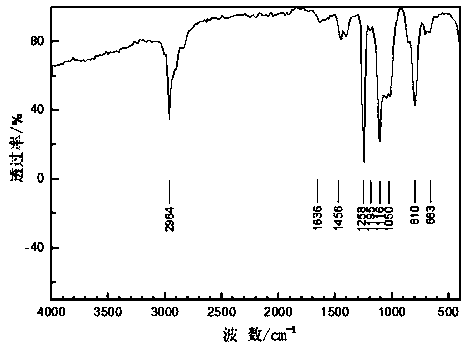

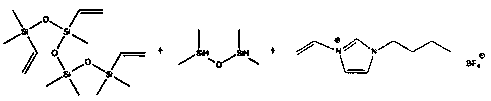

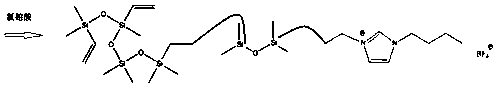

[0023] A preparation method of a fluorosilicone waterproof finishing agent for cotton fabrics, the main scheme of which is as follows:

[0024] Add 0.5g of surfactant and 180g of deionized water into the reaction kettle, mix evenly, add 1g of alkali solution with a mass percentage concentration of 5%, continue to stir for 10min, heat up to 60°C, and then add 5g of Methylcyclotetrasiloxane, 2g of hexamethyldisiloxane and 3g of hexadecyltrimethoxysilane are mixed evenly and then slowly added to the reaction kettle. The addition is controlled within 60 minutes, and the temperature is kept after the addition is completed. After reacting for 5 hours, add 40 g of organic fluorosilicon ionic liquid emulsion, 0.01 g of sodium polyphosphate and 0.1 g of copper naphthenate, stir for 20 min, and then filter to obtain the silicone waterproof finishing agent for cotton fabrics.

[0025] A new type of organofluorosilicon emulsion is prepared according to the following method: 50g of polydim...

Embodiment 2

[0031] A preparation method of a fluorosilicone waterproof finishing agent for cotton fabrics, the main scheme of which is as follows:

[0032] Add 0.7g of surfactant and 190g of deionized water into the reaction kettle, mix evenly, add 4g of alkali solution with a mass percentage concentration of 7%, continue to stir for 15min, then heat up to 70°C, and then add 7g of eight Methylcyclotetrasiloxane, 5g of hexamethyldisiloxane and 4g of hexadecyltrimethoxysilane are mixed evenly and slowly added to the reaction kettle, and the addition is controlled within 70 minutes, and the temperature is kept after the addition After reacting for 8 hours, add 48g of organic fluorine silicon ionic liquid emulsion, 0.04g of sodium polyphosphate and 0.3g of copper naphthenate, stir for 25min and then filter to obtain the silicone waterproof finishing agent for cotton fabrics.

[0033] A new type of organofluorosilicon emulsion is prepared according to the following method: 70g of polydimethylm...

Embodiment 3

[0039] A preparation method of a fluorosilicone waterproof finishing agent for cotton fabrics, the main scheme of which is as follows:

[0040] Add 2.3g of surfactant and 320g of deionized water into the reaction kettle, mix evenly, add 10g of alkali solution with a mass percentage concentration of 10%, continue to stir for 30min, then heat up to 80°C, and then add 13g of octane Methylcyclotetrasiloxane, 7g of hexamethyldisiloxane and 6g of hexadecyltrimethoxysilane are mixed evenly and then slowly added to the reaction kettle, and the addition is controlled within 120min, and the temperature is kept after the addition After reacting for 12 hours, add 60 g of organic fluorosilicon ionic liquid emulsion, 0.1 g of sodium polyphosphate and 0.5 g of copper naphthenate, stir for 30 min and then filter to obtain the silicone waterproof finishing agent for cotton fabrics.

[0041] A new type of organofluorosilicon emulsion is prepared according to the following method: 80g of polydim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com