Scintillation crystal, and preparation method and application thereof

A scintillation crystal and crystal growth technology, applied in crystal growth, chemical instruments and methods, self-solidification method, etc., can solve the problems of weakening the comprehensive advantages and influence of cesium iodide scintillation crystals, and poor crystal light yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

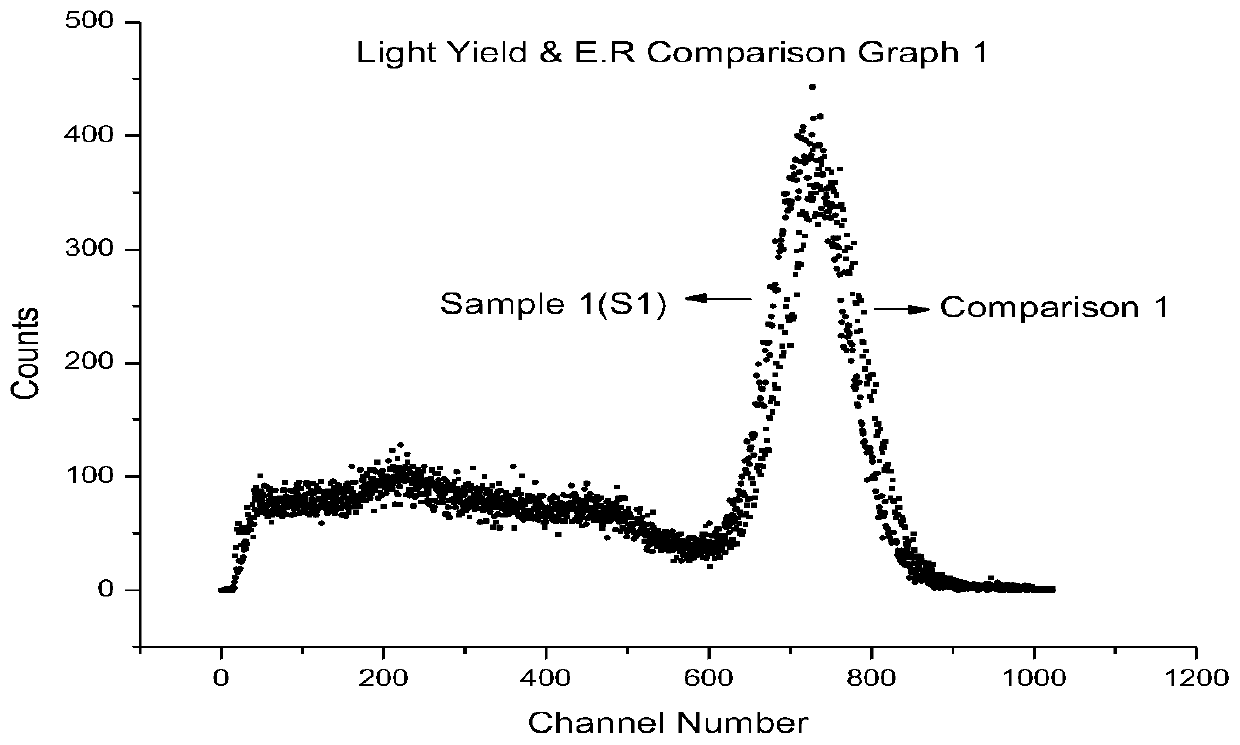

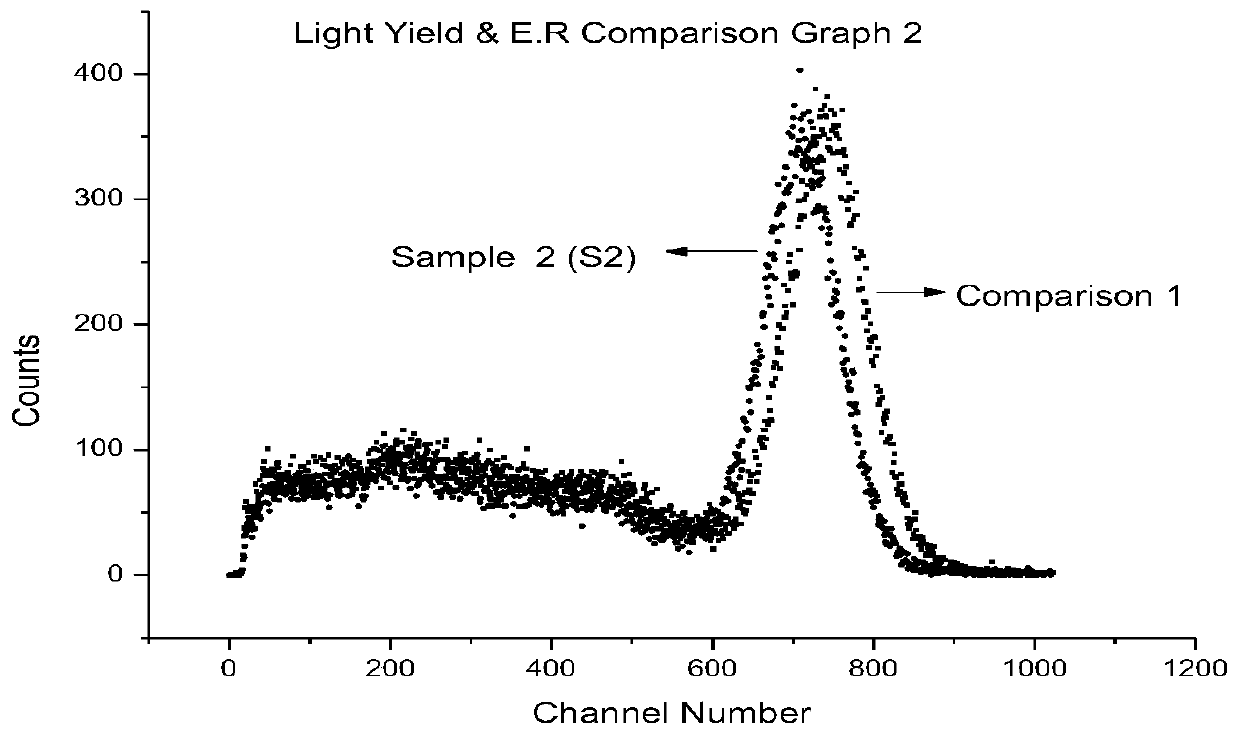

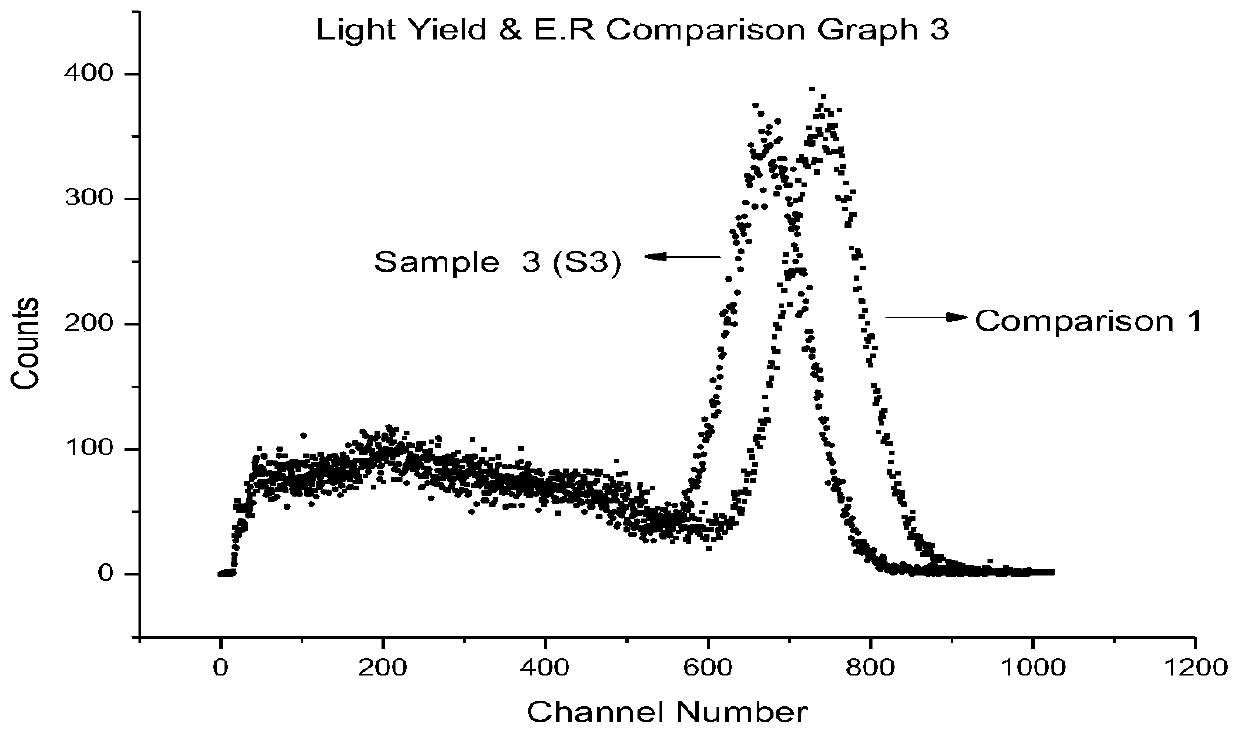

Image

Examples

preparation example Construction

[0033] The second aspect of the present invention provides the preparation method of the scintillation crystal described in the first aspect of the present invention, comprising: after heating and melting the mixture of cesium iodide powder, thallous iodide and cuprous iodide, further crystal growth , prepared to obtain.

[0034] In the preparation method of scintillation crystal provided by the present invention, the molar ratio of cesium iodide powder to thallium iodide is 1:0.05-0.1. In some specific embodiments, the molar ratio of cesium iodide powder to thallium iodide is 1:0.05-0.06; 1:0.06-0.07; 1:0.07-0.08; 1:0.08-0.09; 1:0.09 ~0.1;1:0.05~0.07;1:0.07~0.09;1:0.05~0.08;1:0.08~0.10;1:0.05~0.09;1:0.06~0.09;1:0.06~0.08;or 1:0.07~ 0.1.

[0035] In the preparation method of the scintillation crystal provided by the present invention, the molar ratio of the cesium iodide powder to the cuprous iodide is 1:0.01-0.1. In some specific embodiments, the molar ratio of cesium iodi...

Embodiment 1

[0052] 1. Weigh 10Kg of high-purity (4N) cesium iodide raw material into the quartz crucible in the self-developed vacuum sublimation desublimation purification tank, turn on the vacuum pump, when the vacuum degree in the tank is higher than 1.0×10 -2 At Pa, start to heat up to 170°C and keep the temperature until the sublimation of the cesium iodide raw material is completed, and the maximum heating temperature of the quartz crucible containing the material does not exceed 175°C;

[0053] 2. Take out the cesium iodide material that has been sublimated and desublimated in step 1 and put it into a quartz tube coated with carbon film. After vacuuming, perform the first crystal growth, and remove about one-fifth of the top of the grown crystal material to be used later;

[0054] 3. Dissolve the crystallization material in step 2 into pure water at a constant temperature of 40°C to form a cesium iodide saturated solution, and add hydroxylamine (NH 2 OH), and use hydrazine hydrate...

Embodiment 2

[0063] 1. Weigh 10Kg of high-purity (4N) cesium iodide raw material into the quartz crucible in the self-developed vacuum sublimation desublimation purification tank, turn on the vacuum pump, when the vacuum degree in the tank is higher than 1.0×10 -2 At Pa, start to heat up to 170°C and keep the temperature until the sublimation of the cesium iodide raw material is completed, and the maximum heating temperature of the quartz crucible containing the material does not exceed 175°C;

[0064] 2. Take out the cesium iodide material that has been sublimated and desublimated in step 1 and put it into a quartz tube coated with carbon film. After vacuuming, perform the first crystal growth, and remove about one-fifth of the top of the grown crystal material to be used later;

[0065] 3. Dissolve the crystallization material in step 2 into pure water at a constant temperature of 50°C to form a cesium iodide saturated solution, and add hydroxylamine (NH 2 OH), and use hydrazine hydrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com