Biogas desulfurization and purification process

A purification process and biogas desulfurization technology, applied in the field of biogas treatment, can solve the problems of complicated desulfurization process, poor stability of desulfurization agent, difficult to store for a long time, low desulfurization efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

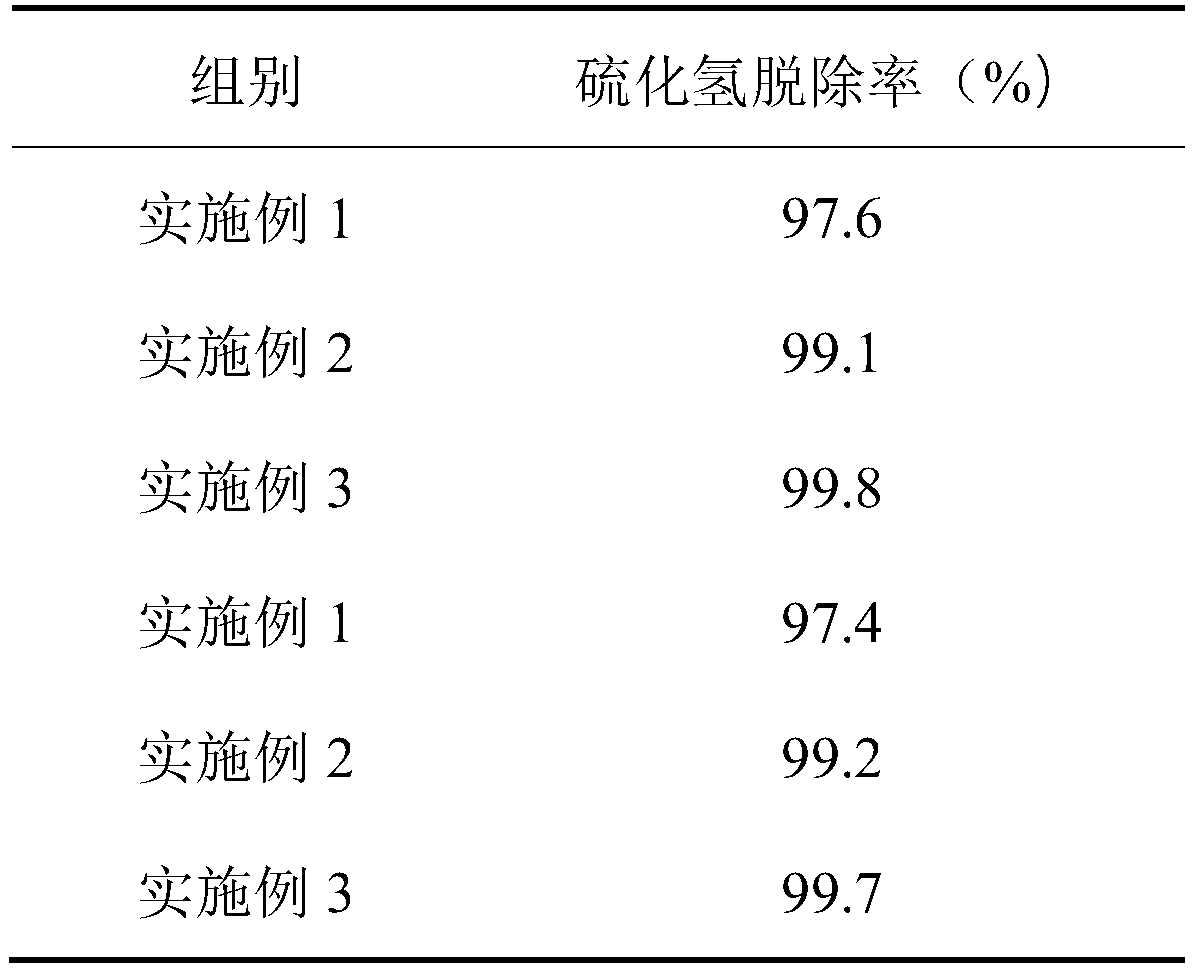

Examples

Embodiment 1

[0019] A biogas desulfurization purification process, which absorbs hydrogen sulfide in biogas through an absorption tower. The liquid-gas flow ratio of the absorption liquid to the sulfur-containing biogas is 0.01:1. The absorption liquid used includes the following components: water, complexed iron, Complex ferrous, N, N-dihydroxyethylpiperazine, 7-diethylamino-4-methylcoumarin, 2-hydroxymethyl-15-crown-5, sodium carbonate and sodium bicarbonate buffer system, wherein the concentration of iron element in complexed iron is 300mg / L, the concentration of iron element in complexed ferrous iron is 700mg / L, the concentration of N,N-dihydroxyethylpiperazine is 30mg / L, 7-diethyl The concentration of amino-4-methylcoumarin is 3mg / L, the concentration of 7-diethylamino-4-methylcoumarin is 15mg / L, and the solution pH is controlled by sodium carbonate and sodium bicarbonate buffer system. 7.5.

[0020] In this embodiment, the complexing ligands of the complexed iron and ferrous complex...

Embodiment 2

[0027] A biogas desulfurization and purification process. The hydrogen sulfide in the biogas is absorbed through the absorption tower. The liquid-gas ratio of the absorption liquid to the sulfur-containing biogas is 0.02:1. The absorption liquid used includes the following components: water, complex iron, complex Ferrous iron, N, N-dihydroxyethylpiperazine, 7-diethylamino-4-methylcoumarin, 2-hydroxymethyl-15-crown-5, sodium carbonate and sodium bicarbonate buffer system , wherein the concentration of iron in complexed iron is 800mg / L, the concentration of iron in complexed ferrous is 500mg / L, the concentration of N,N-dihydroxyethylpiperazine is 45mg / L, and the concentration of 7-diethylamino The concentration of -4-methylcoumarin is 6mg / L, the concentration of 7-diethylamino-4-methylcoumarin is 20mg / L, and the pH of the solution is controlled by sodium carbonate and sodium bicarbonate buffer system to be 9.0 .

[0028] In this embodiment, the complexing ligand of the complexe...

Embodiment 3

[0035] A biogas desulfurization and purification process. The hydrogen sulfide in the biogas is absorbed through the absorption tower. The liquid-gas ratio of the absorption liquid to the sulfur-containing biogas is 0.016:1. The absorption liquid used includes the following components: water, complex iron, complex Ferrous iron, N, N-dihydroxyethylpiperazine, 7-diethylamino-4-methylcoumarin, 2-hydroxymethyl-15-crown-5, sodium carbonate and sodium bicarbonate buffer system , wherein the concentration of iron in complexed iron is 500mg / L, the concentration of iron in complexed ferrous is 600mg / L, the concentration of N,N-dihydroxyethylpiperazine is 35mg / L, and the concentration of 7-diethylamino The concentration of -4-methylcoumarin is 5mg / L, the concentration of 7-diethylamino-4-methylcoumarin is 15mg / L, and the pH of the solution is controlled to be 8.5 by sodium carbonate and sodium bicarbonate buffer system .

[0036] In this embodiment, the complexing ligands of the comple...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com