Compound polyether demulsifier and preparation method thereof

A technology of demulsifier and polyether, which is applied in the field of high-efficiency and environmentally friendly compound polyether demulsifier and its preparation, can solve the problems of large amount of demulsifier and environmental pollution, so as to improve the demulsification effect and reduce environmental pollution Small, aroma-increasing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

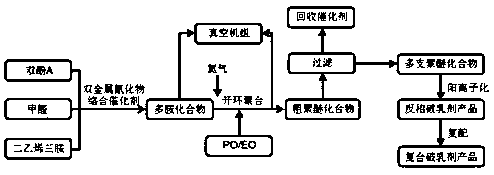

Method used

Image

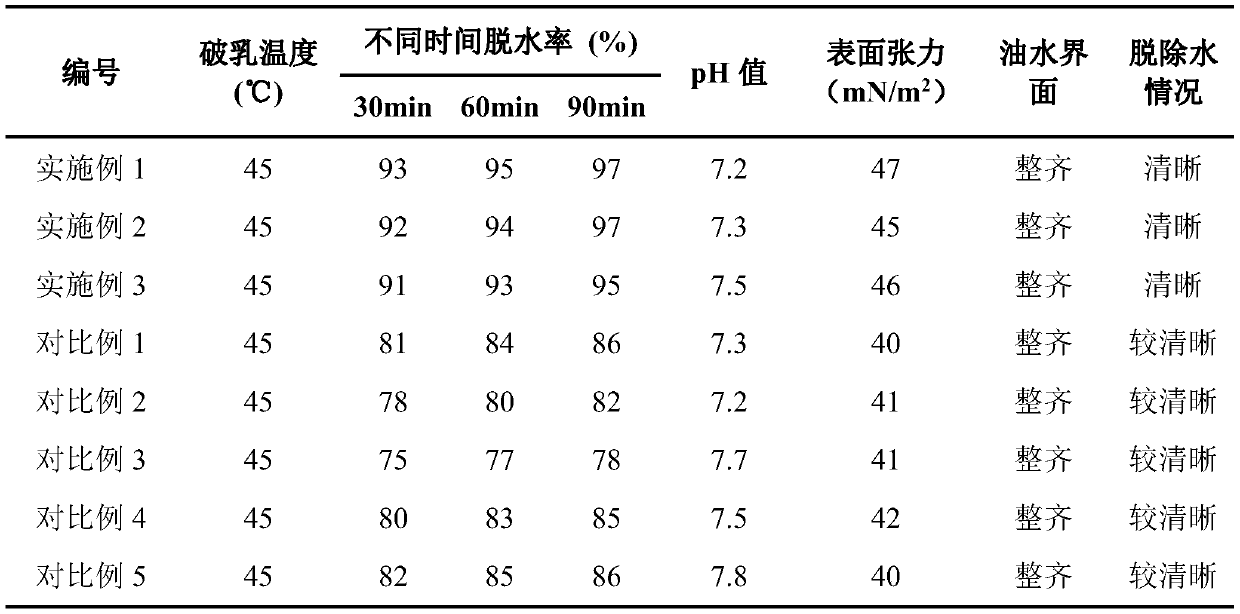

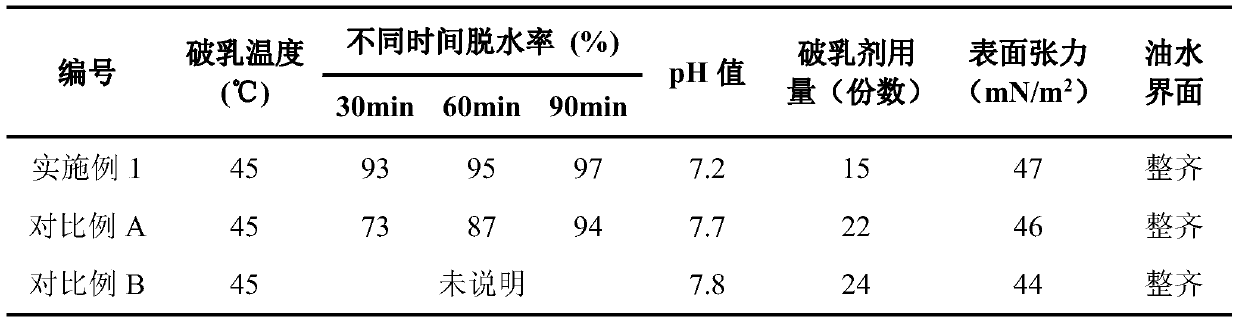

Examples

Embodiment 1

[0030] The invention discloses a composite polyether demulsifier, which is composed of the following mass fractions: 40% of multi-branched cationic polyether reverse phase demulsifier, 10% of PRJ-1 demulsifier, polyaluminum chloride ( PAC) and FeCl 3 ·6H 2 O mixture 15%, toluene diisocyanate 15%.

[0031] The present invention also discloses a method for the above compound polyether demulsifier, comprising the following steps:

[0032] (1) Bisphenol A and double metal cyanide are placed in the reactor for reflux reaction to obtain a mixed solution of branched polyamine compound and double metal cyanide; the molar ratio of bisphenol A to double metal cyanide is 31:2 ;

[0033] (2) Transfer the mixed solution obtained in step (1) to the high-pressure lid, heat up to 120° C. and vacuumize after sealing;

[0034] (3) Slowly and continuously add ethylene oxide and propylene oxide to the high-pressure cover, and continue to react after the feeding ends to obtain a hyperbranched ...

Embodiment 2

[0038] The invention discloses a composite polyether demulsifier, which is composed of the following mass fractions: 35% of multi-branched cationic polyether reverse phase demulsifier, 25% of PRJ-1 demulsifier, polyaluminum chloride ( PAC) 20%, diisocyanate 15%.

[0039] The present invention also discloses a method for the above compound polyether demulsifier, comprising the following steps:

[0040] (1) Diethylenetriamine and double metal cyanide are placed in the reactor for reflux reaction to obtain a mixed solution of branched polyamine compound and double metal cyanide; the mol ratio of diethylenetriamine and double metal cyanide is 31 :2;

[0041] (2) Transfer the mixed solution obtained in step (1) to the high-pressure lid, heat up to 100° C. and vacuumize after sealing;

[0042] (3) Slowly and continuously add ethylene oxide and propylene oxide to the high-pressure cover, continue to react after the addition, and obtain a hyperbranched polyether compound. The pressu...

Embodiment 3

[0046] The invention discloses a compound polyether demulsifier, which is composed of the following substances in mass fraction: 45% of multi-branched cationic polyether reverse phase demulsifier, 30% of PRJ-1 demulsifier, FeCl 3 ·6H 2 O 15%, diisocyanate 10%.

[0047] The present invention also discloses a method for the above compound polyether demulsifier, comprising the following steps:

[0048] (1) Formaldehyde and double metal cyanide are placed in the reactor for reflux reaction to obtain a mixed solution of branched polyamine compound and double metal cyanide; the mol ratio of formaldehyde and double metal cyanide is 31:2;

[0049] (2) Transfer the mixed solution obtained in step (1) to the high-pressure lid, heat up to 150° C. and vacuumize after sealing;

[0050] (3) Slowly and continuously add ethylene oxide and propylene oxide to the high-pressure cover, and continue to react after the feeding ends to obtain a hyperbranched polyether compound. The reaction cover ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com