Polycarboxylate superplasticizer for machine-made sand concrete prestressed component and preparation method of polycarboxylate superplasticizer

A technology of polycarboxylate and concrete, which is applied in the field of building materials, can solve the problems of reducing the application effect of polycarboxylate water reducers, having no dispersion ability, and affecting the dispersion effect, so as to improve production progress, formwork turnover rate, and excellent appearance quality. The effect of holes and smooth appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

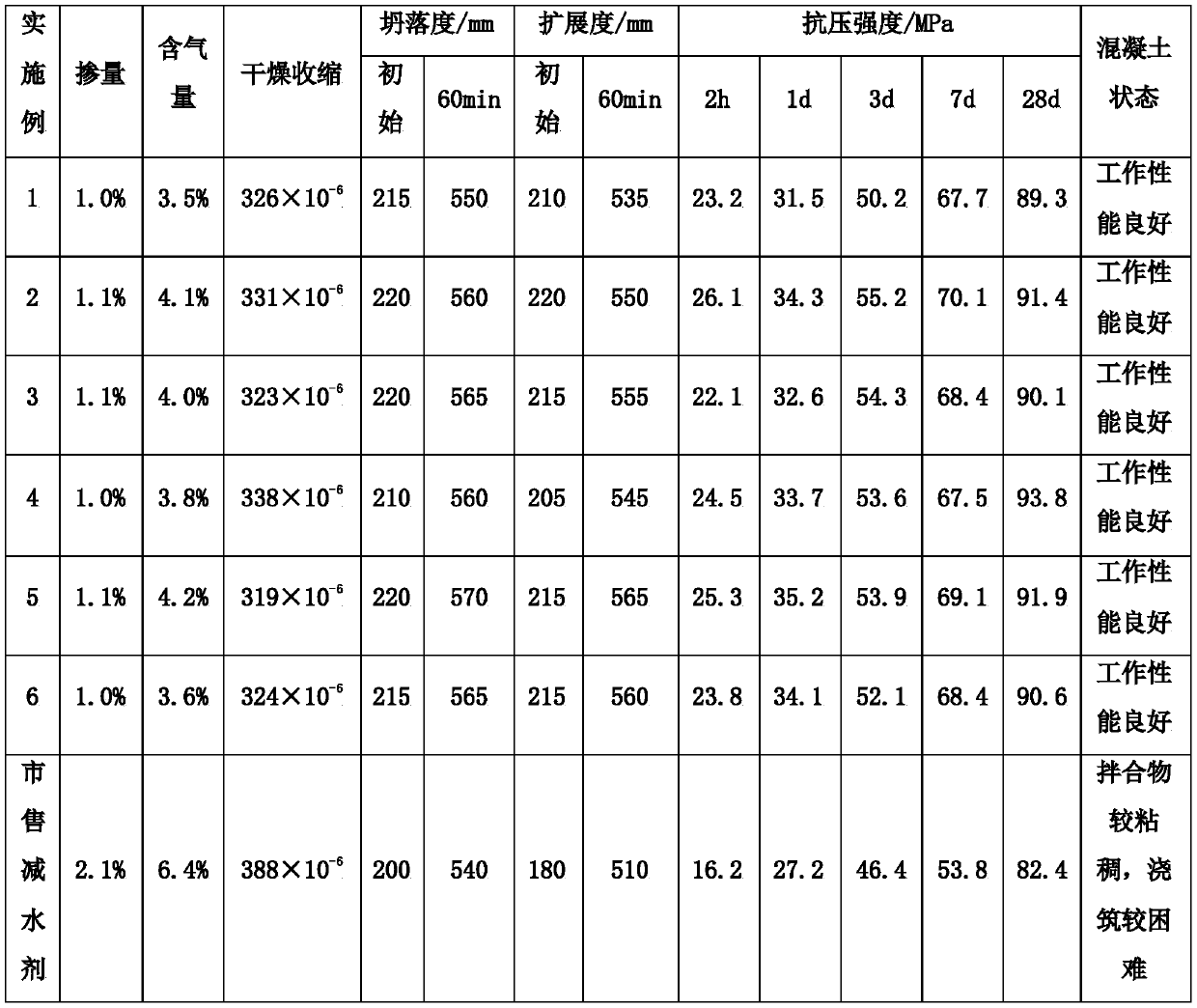

Examples

Embodiment 1

[0019] Add 30 parts of isobutylene alcohol polyoxyethylene ether macromonomer, 20 parts of 4-hydroxybutyl vinyl polyoxyethylene ether macromonomer, methoxy polyethylene glycol unsaturated carboxylate macromonomer into the reaction kettle 20 parts, 10 parts of maleic acid-β-cyclodextrin, 9 parts of unsaturated phosphoric acid monoester, 1 part of unsaturated phosphoric acid diester, 1 part of methacryloyloxyethyl trimethylammonium chloride, dimethyl 1 part of diallyl ammonium chloride, 3 parts of 2-acrylamide-2-methylpropanesulfonic acid and deionized water, blow in nitrogen, stir until all the raw materials are dissolved; add 1 part of H 2 o 2 Solution (30%), after stirring for 15 minutes, add A and B liquids dropwise at the same time, A liquid is an aqueous solution of 5 parts of styrene, 15 parts of acrylic acid, 10 parts of methacrylic acid, 5 parts of maleic anhydride and deionized water, B The liquid is an aqueous solution prepared by 0.2 parts of 3-mercaptopropionic aci...

Embodiment 2

[0021] Add 70 parts of isobutylene alcohol polyoxyethylene ether macromonomer, 30 parts of 4-hydroxybutyl vinyl polyoxyethylene ether macromonomer, methoxy polyethylene glycol unsaturated carboxylate macromonomer into the reactor 40 parts, 40 parts of maleic acid-β-cyclodextrin, 25 parts of unsaturated phosphoric acid monoester, 5 parts of unsaturated phosphoric acid diester, 10 parts of methacryloyloxyethyl trimethyl ammonium chloride, dimethyl 5 parts of diallyl ammonium chloride, 10 parts of 2-acrylamide-2-methylpropanesulfonic acid and deionized water, nitrogen, and stir until the raw materials are completely dissolved; add 2.8 parts of H 2 o 2 Solution (30%), after stirring for 15 minutes, add A and B liquids dropwise at the same time, A liquid is an aqueous solution of 15 parts of styrene, 30 parts of acrylic acid, 15 parts of methacrylic acid, 15 parts of maleic anhydride and deionized water, B The liquid is an aqueous solution prepared by 0.5 parts of 3-mercaptopropio...

Embodiment 3

[0023] Add 75 parts of 4-hydroxybutyl vinyl polyoxyethylene ether macromonomer, 30 parts of methoxy polyethylene glycol unsaturated carboxylate macromonomer, maleic acid-β-cyclodextrin into the reaction kettle 25 parts, 18 parts of unsaturated phosphoric acid monoester, 2 parts of unsaturated phosphoric acid diester, 10 parts of methacryloxyethyltrimethyl ammonium chloride, 5 parts of dimethyl diallyl ammonium chloride and deionized Water, nitrogen gas, stirring until the raw materials are completely dissolved; add 1.8 parts of H at one time 2 o 2 solution (30%), after stirring for 15 minutes, add A and B liquids dropwise at the same time, A liquid is an aqueous solution of 10 parts of styrene, 30 parts of acrylic acid, 15 parts of methacrylic acid and deionized water, and B liquid is 3-mercaptopropane An aqueous solution prepared by 0.6 parts of ascorbic acid, 0.2 parts of ascorbic acid, and deionized water; the time for adding liquid A is 2.5 hours, and the time for adding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com