A micro-impact deformation type flat plate rapid derusting equipment

A flat plate and micro-impact technology, which is applied in metal processing equipment, grinding/polishing equipment, stamping machines, etc., can solve problems such as unsatisfactory effects, excessive grinding, and easy-to-corrosion steel plates, etc. Avoid deep grinding and facilitate the effect of accelerated impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

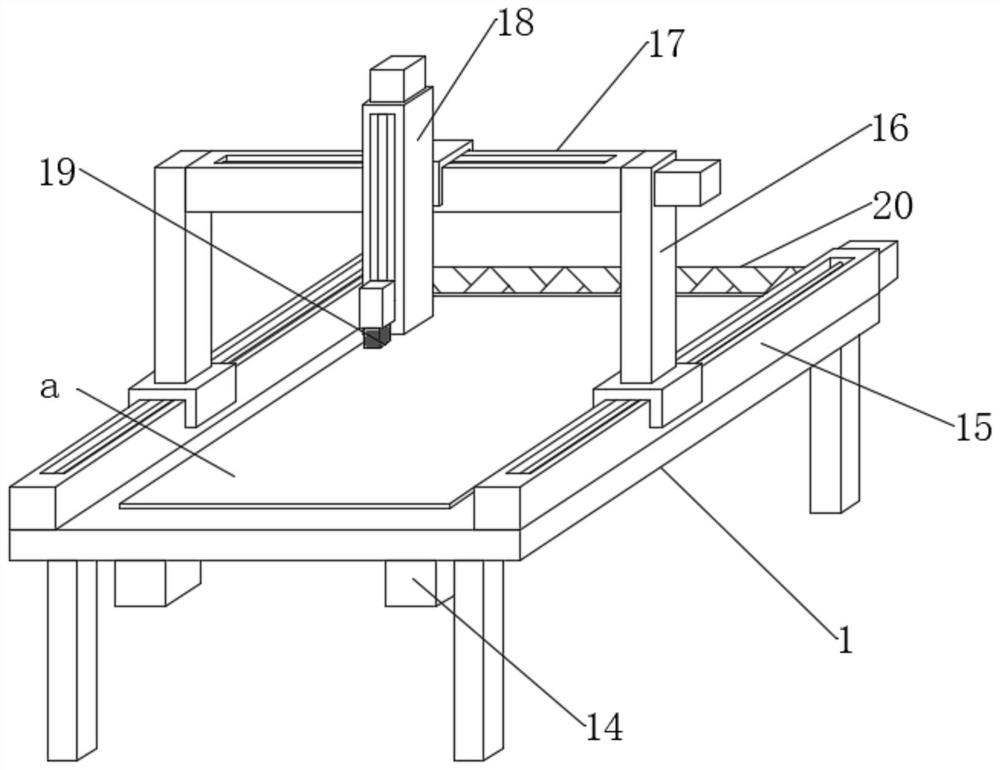

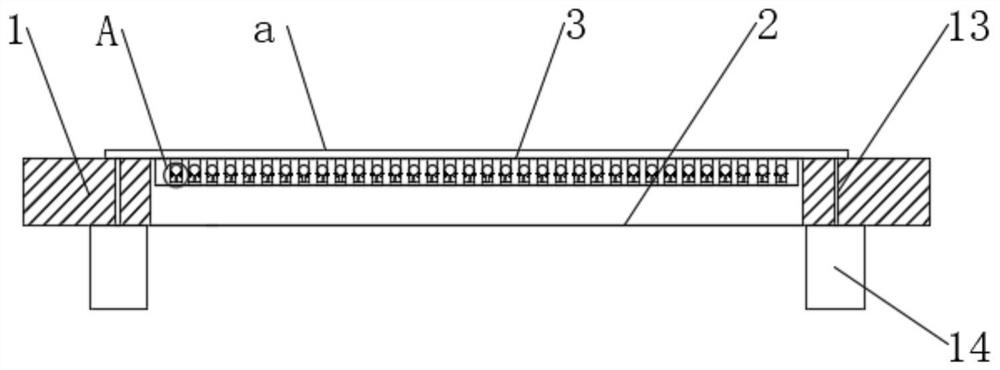

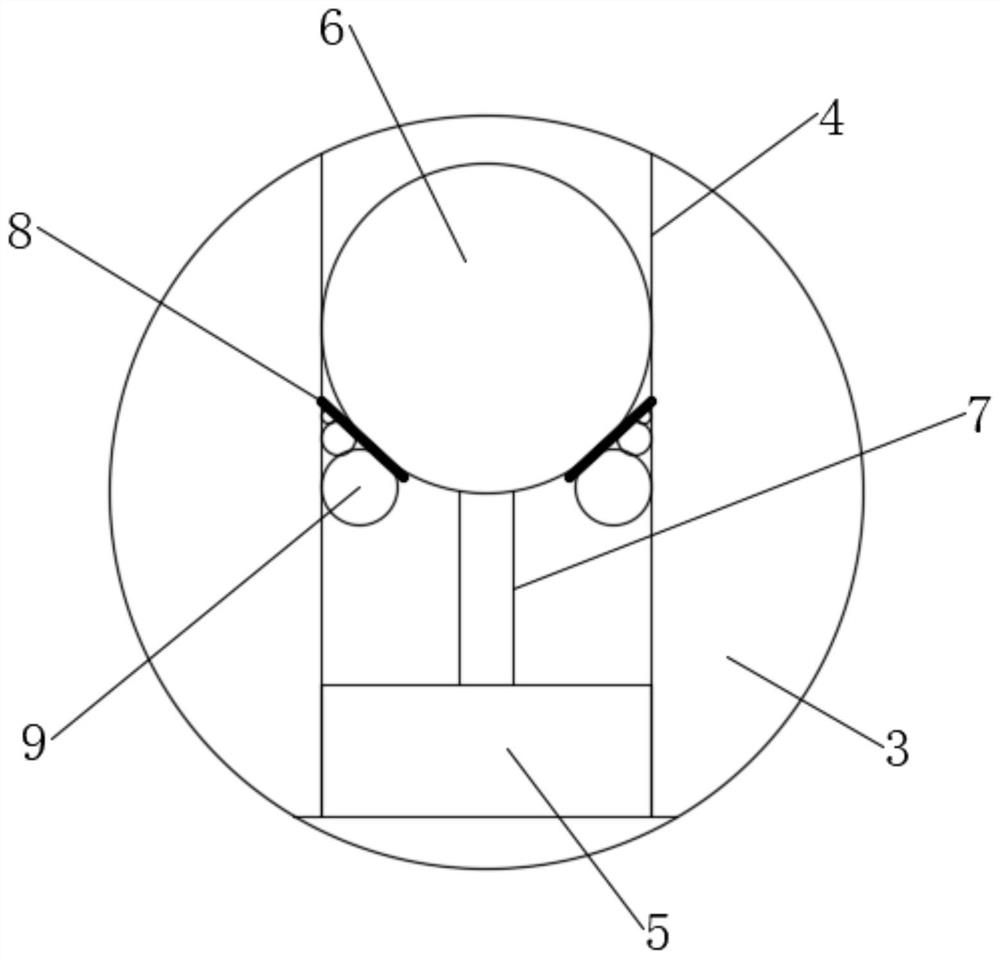

[0045] see figure 1 , a kind of micro-impact deformation type fast derusting equipment for flat plates, including a workbench 1, on which four adsorption holes 13 located at the corners of the plate to be derusted are dug, and the lower end of the workbench 1 is fixedly connected with a plurality of Vacuum pump 14, and the vacuum pump 14 is connected with the adsorption hole 13 through the pipeline, and the plate a to be derusted is fixed through the effect of vacuum adsorption to prevent it from being displaced when it is impacted. A three-axis positioning assembly is installed on the upper end of the worktable 1. The three-axis positioning assembly is provided with dense steel wire brushes 19, which are used to clean the corrosion on the surface of the plate. For different degrees of corrosion, different heights are used to scrape off the three-axis positioning assembly. The three-axis positioning assembly includes a pair of first An electric slide 15, the first electric sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com