CeO2-based composite solid electrolyte material and preparation method thereof

A solid electrolyte and mixed liquid technology, which is applied in circuits, fuel cells, electrical components, etc., can solve the problem that the electrical conductivity needs to be improved, and achieve the effects of improving electrochemical performance, fewer pores, and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

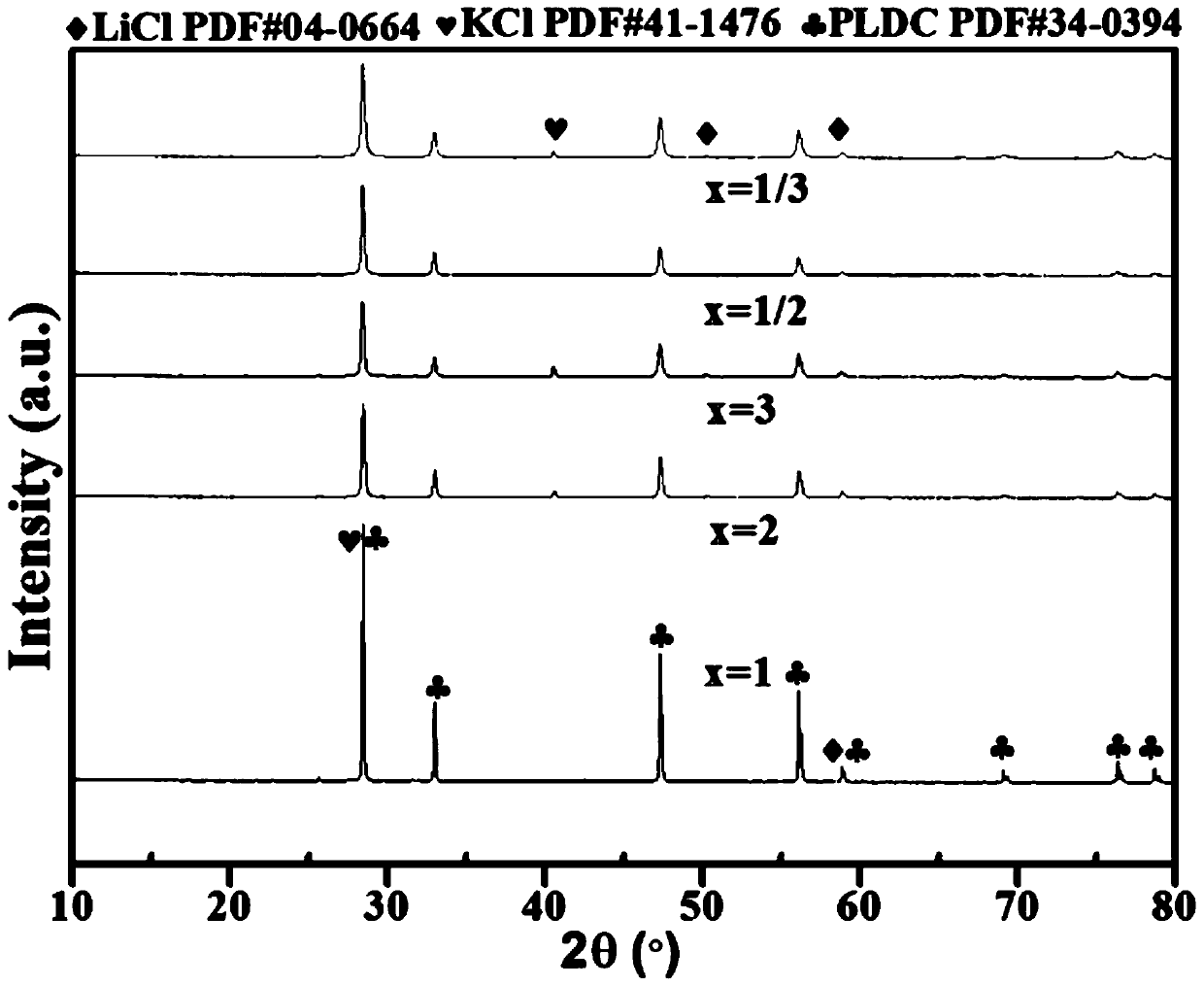

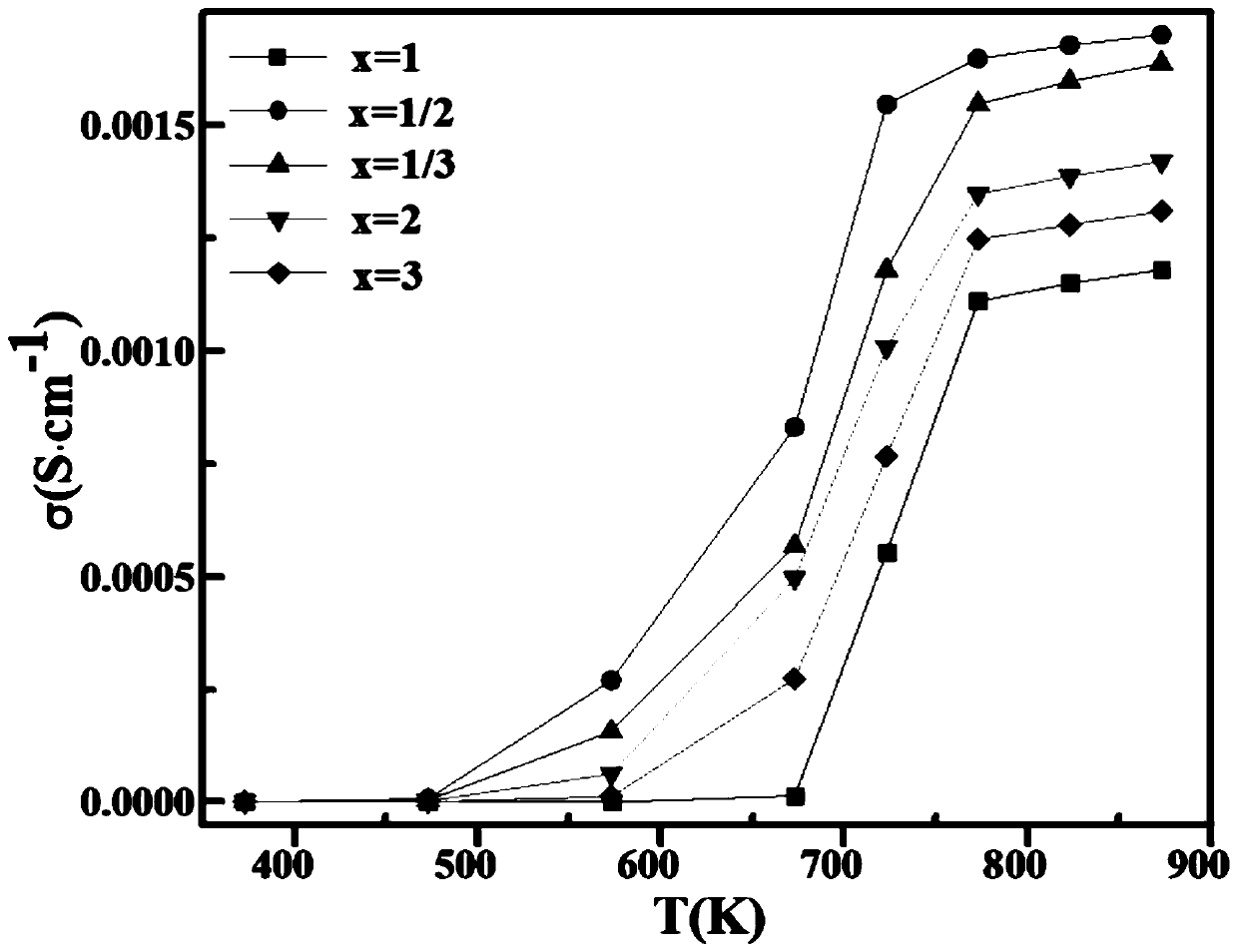

[0029] a CeO 2 matrix composite solid electrolyte material, the general structural formula is as follows: Ce 0.8 PR 0.1 La 0.1 o 2–δ x(Li 0.5 K 0.5 Cl), where δ is the amount of oxygen deficiency.

Embodiment 2

[0031] a CeO 2 matrix composite solid electrolyte material, the general structural formula is as follows: Ce 0.8 PR 0.1 La 0.1 o 2–δ x(Li 0.5 K 0.5 Cl), where δ is the amount of oxygen deficiency, 1 / 3≤x≤3.

[0032] CeO 2 The preparation method of matrix composite solid electrolyte material comprises the following steps:

[0033] S1, according to the general structural formula Ce 0.8 PR 0.1 La 0.1 o 2–δ x(Li 0.5 K 0.5 Cl), take by weighing 鐠 salt, cerium salt, lanthanum salt, potassium chloride and lithium chloride, mix with an appropriate amount of organic acid, then add water to dissolve, to obtain a mixed solution;

[0034] S2, adjusting the pH of the mixed solution to neutral to obtain a precursor;

[0035] S3. Microwave combustion reaction of the precursor at 800-1200W for 10-30min, then dry at 120-150°C for 0.5-2h, and ball mill to obtain CeO 2 based composite solid electrolyte materials.

[0036] Wherein, the molar amount of the organic acid=(1-1.5)×(nCe+...

Embodiment 3

[0041] a CeO 2 Based composite solid electrolyte material, its preparation method comprises the following steps:

[0042] S1, according to the general structural formula Ce 0.8 PR 0.1 La 0.1 o 2–δ x(Li0.5 K 0.5 Cl), x=1 / 3, weighed nitrate, cerium nitrate, lanthanum nitrate, potassium chloride and lithium chloride, mixed with an appropriate amount of tartaric acid, then dissolved in water to obtain a mixed solution;

[0043] S2, adjusting the pH of the mixed solution to neutral to obtain a precursor;

[0044] S3. Microwave the reaction of the precursor at 1000W for 15min, then dry at 140°C for 1h, and ball mill to obtain CeO 2 based composite solid electrolyte materials.

[0045] Wherein, the molar amount of tartaric acid=1.2×(nCe+nPr+nLa+nLi+nK).

[0046] a CeO 2 Based composite solid electrolyte, its preparation method is as follows:

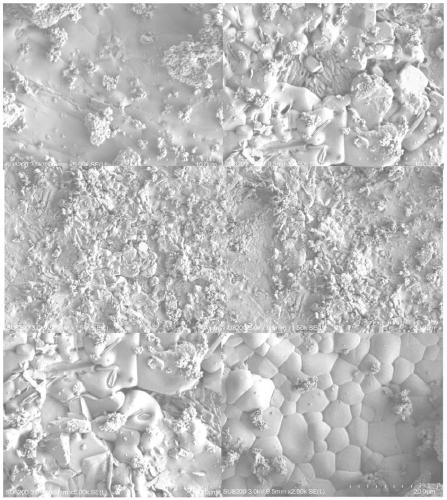

[0047] (1) the above prepared CeO 2 After the matrix composite solid electrolyte material is dried, add PVA binder solution with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com