Screw temperature control film clamping device

A film and screw technology, used in measuring devices, detachable fasteners for friction clamping, instruments, etc., can solve the problems of unfavorable film inflation, measurement and control, thread occlusion, etc., to achieve simple structure, clamping The effect of large force and high conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

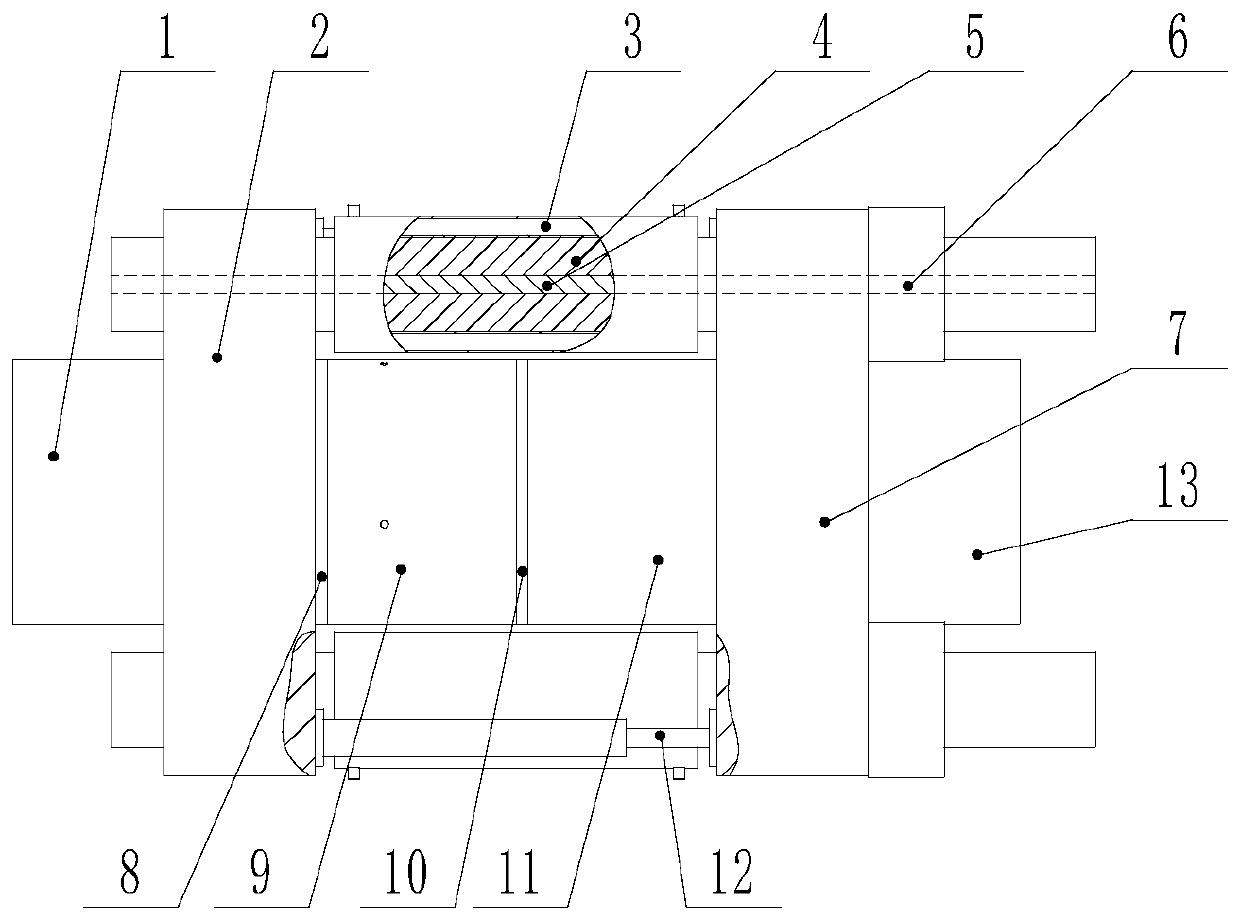

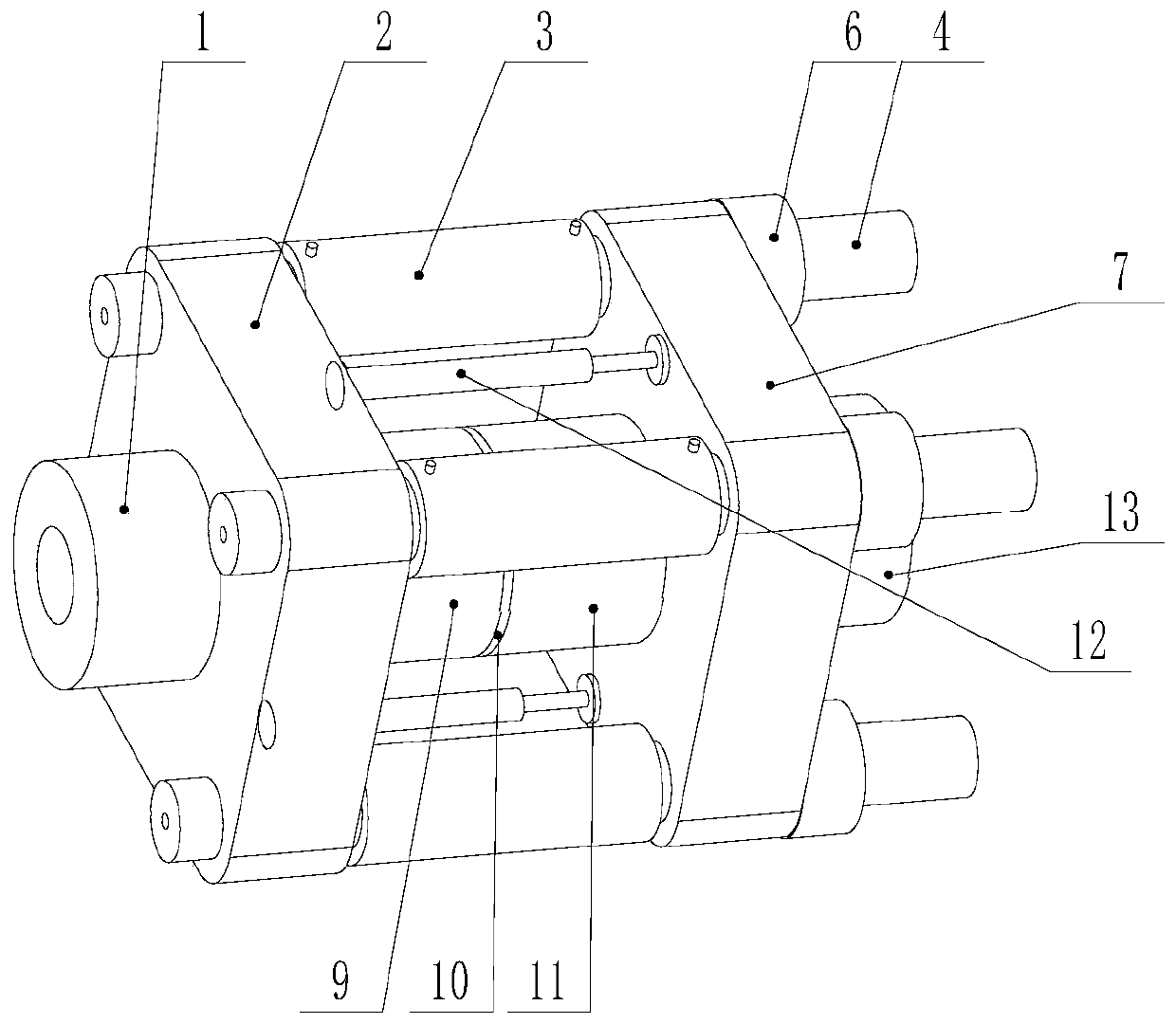

[0030] Such as figure 1 , 2 As shown, the screw temperature control membrane device of this embodiment includes a driving section 1, a left flange 2, a water cooling jacket 3, a connecting screw 4, a heater 5, a fastening nut 6, a right flange 7, a diaphragm I 8, a clip Diaphragm ring I9, diaphragm II10, sandwich ring II11, telescopic cylinder 12 and driven section 13;

[0031] Driving section 1: It is the upstream pipe section of the shock tube, and the interior is a cylindrical cavity. During the test, the cavity is filled with high-pressure driving gas. The right end of the driving section 1 is provided with an external thread, which is connected with the internal thread hole I in the center of the left flange 2. make threaded connections;

[0032] Left flange 2: Installed on the right end of the driving section 1 through threads, the center is provided with an internally threaded hole I, and the four corners are processed with internally threaded holes II uniformly distr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com