High temperature electric heating furnace for furnace body replacement and rapid material cooling

A rapid cooling, electric heating furnace technology, applied in the field of high temperature electric heating furnace, can solve the problems of furnace parts heating conditions and temperatures that cannot be seen externally, no cooling system, slow cooling speed, etc., to meet the requirements of heat treatment process, ensure Product quality, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following further describes the present invention with reference to the drawings and specific embodiments:

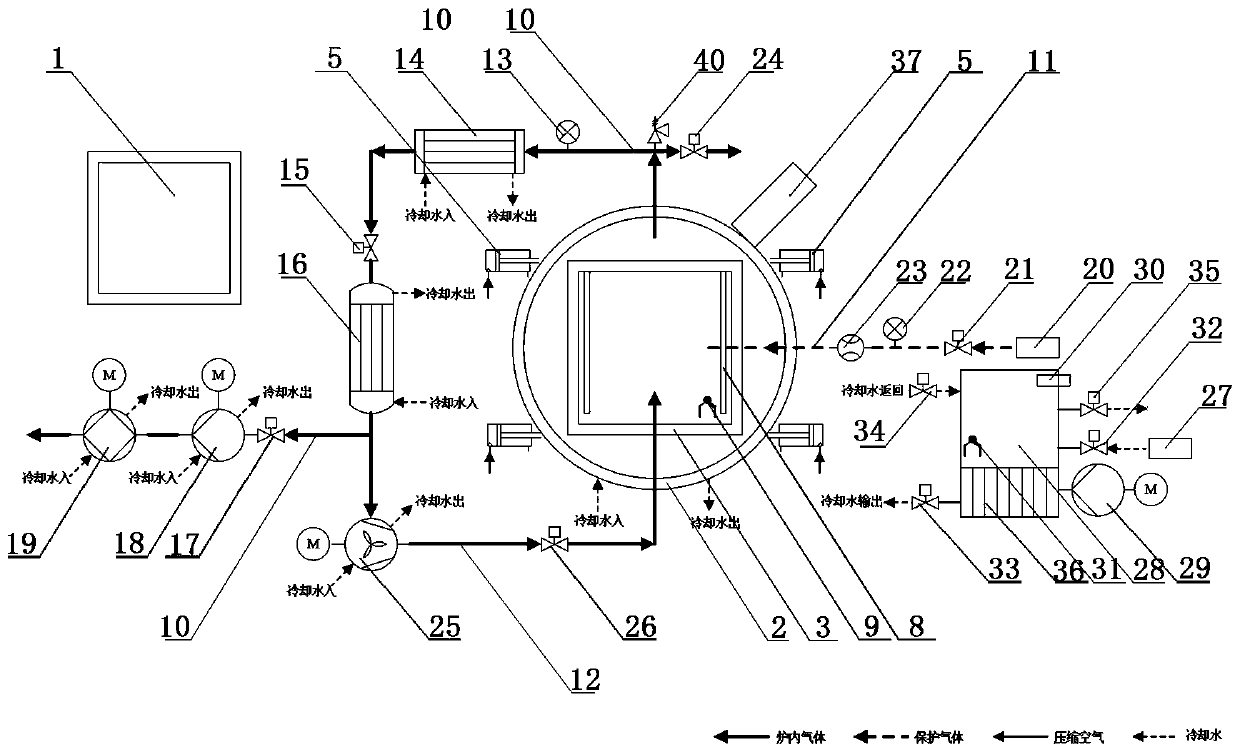

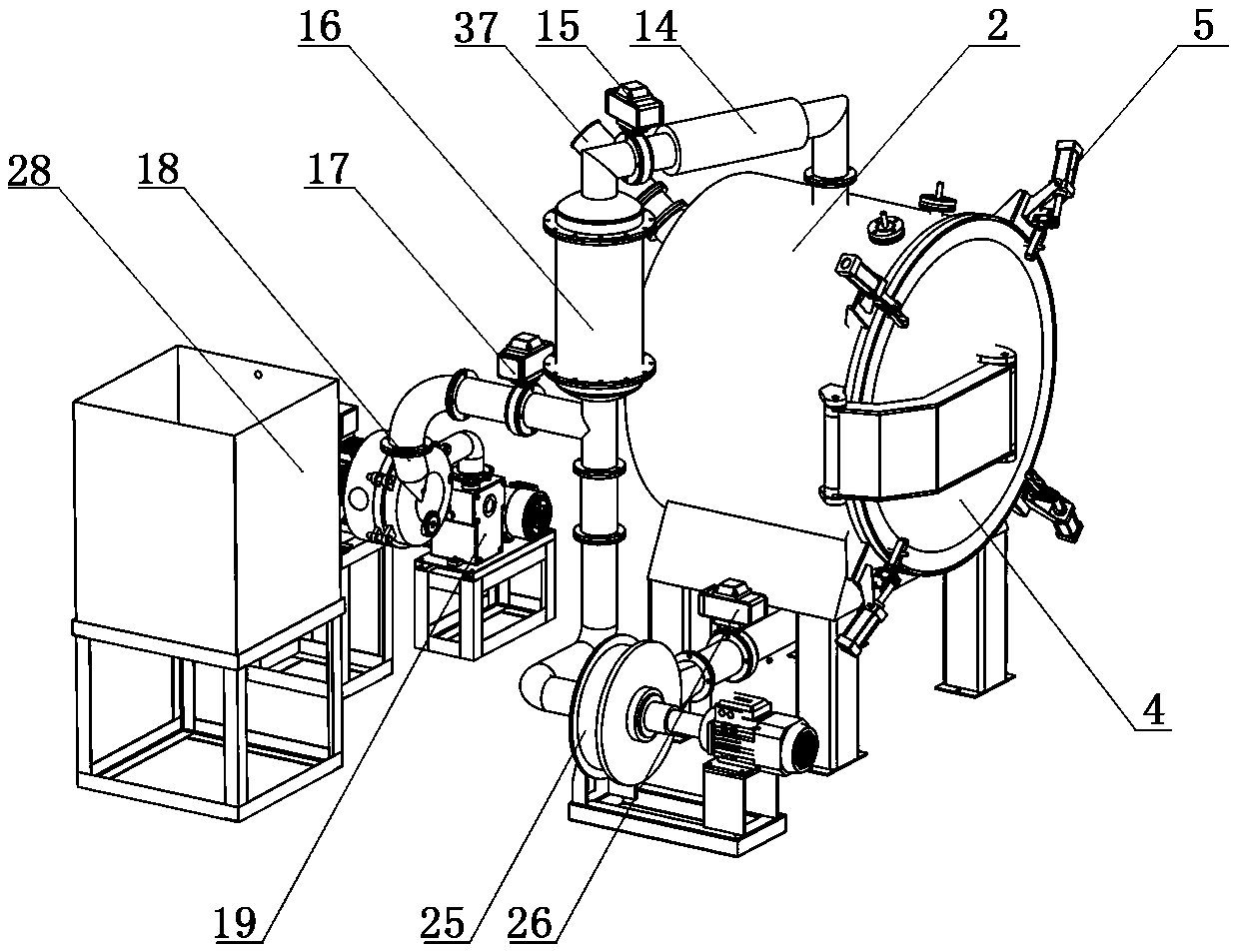

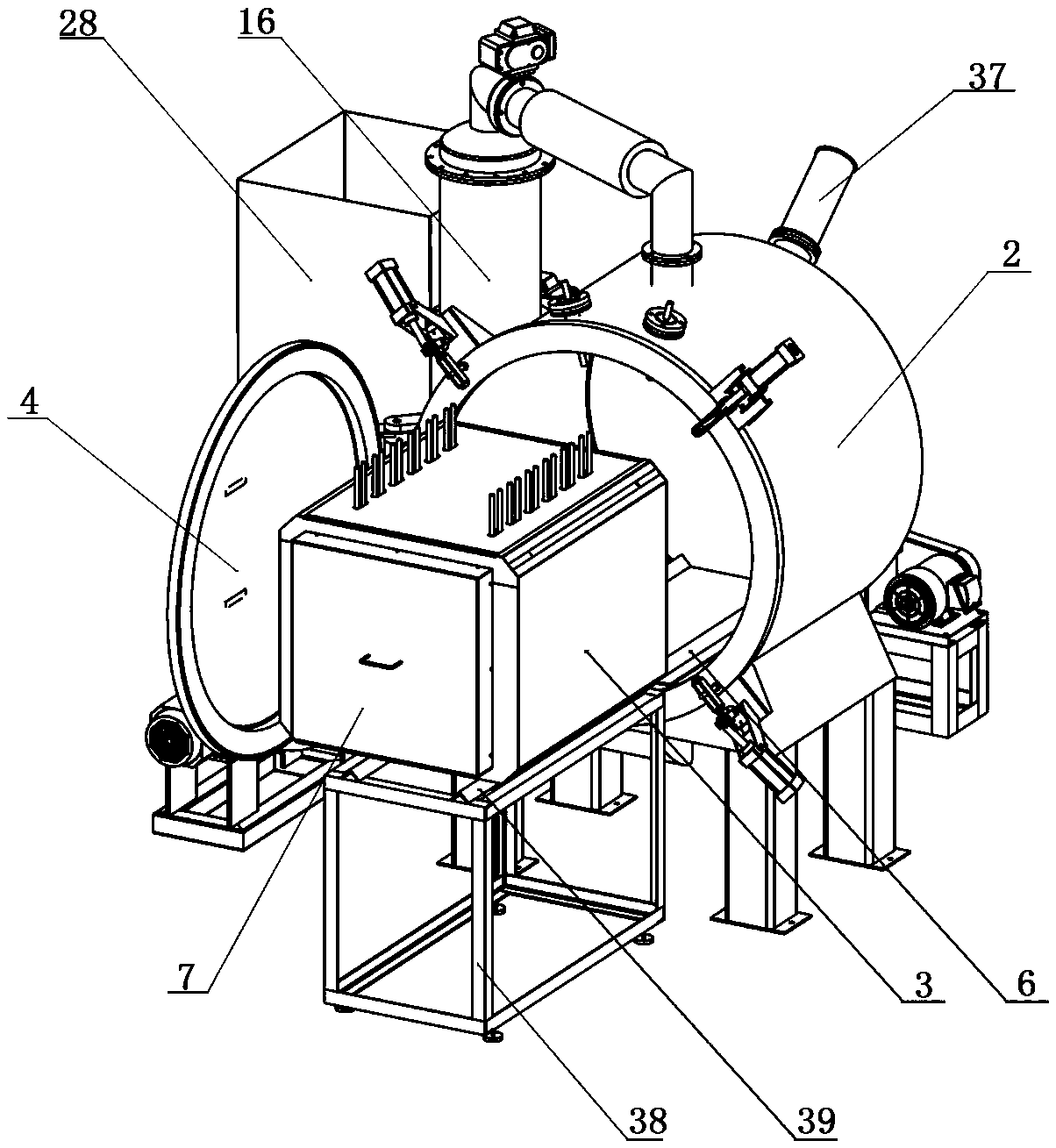

[0028] The working principle of the present invention is shown as figure 1 As shown, the appearance diagram of the device of the embodiment of the present invention is as follows figure 2 with image 3 Shown. A high-temperature electric heating furnace capable of replacing furnace bodies and rapidly cooling materials includes an electric control system 1, a heating furnace body, a vacuum atmosphere system, a water cooling system and a high-temperature thermal imager. The electric control system 1 uses Siemens S7-1200 programmable controller to control the entire working process of the electric heating furnace, and at the same time, it performs closed-loop control of the heating temperature, vacuum and atmosphere pressure of the electric heating furnace. The heating furnace body includes a shell 2, a furnace body 3, a sealed door 4, and a compression cylinder 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com