Gas flow regulation device for rotary spray pipe value of solid rocket-ramjet engine

A gas flow regulation and ramjet technology, which is applied in rocket engine devices, ramjet engines, jet propulsion devices, etc., can solve the problems of poor gas flow regulation capability, complex transmission structure, poor working reliability, etc., and achieve accurate gas flow. Adjustment, transmission ratio is accurate and reliable, the effect of reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

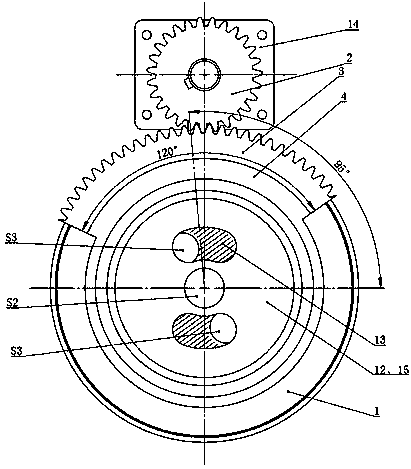

[0063] combine figure 1 and figure 2 , when the driving motor 14 drives the driving gear 3 through the output shaft, and then drives the driven gear 2 to rotate, so that the symmetrical axis of the driven gear 2 and the horizontal line of the fixed valve head 12 form a position of 45°, the effective gas outlet flow area of the combustion chamber at this time S 1 The gas effective inlet flow area S of the supplementary combustion chamber 4 equal, that is, S 1 =S 2 +2S 3 =S 4 , the adjustment ratio of the effective gas outlet of the combustion chamber to the effective inlet flow area of the secondary combustion chamber is 1:1, and the engine is in a low flow working state.

Embodiment 2

[0065] combine figure 1 and image 3 , the structure of this embodiment is the same as that of Embodiment 1. When the axis of symmetry of the driven gear 2 is at a 95° position to the horizontal line of the fixed valve head 12, the central hole of the rotary valve body 13 and the outlets of the two arc-shaped holes are combined. The area is equal, that is, S 2 =2S 3 , then the effective gas outlet flow area of the combustor is S 1 =S 2 +2S 3 =2S 2 = S 4 , at this time, the adjustment ratio of the effective gas outlet of the combustion chamber to the effective inlet flow area of the supplementary combustion chamber is 1:2, and the engine is in a medium flow working state.

Embodiment 3

[0067] combine figure 1 and Figure 4 The structural form of this embodiment is the same as that of Embodiment 1. When the axis of symmetry of the driven gear 2 is at a position of 135° to the horizontal line of the fixed valve head 12, the rotary valve body 13 is completely opposite to the two arc-shaped holes of the solid valve head. Blocking, the effective gas outlet flow area of the combustion chamber is the central hole area S of the rotary valve body 13 1 =S 2 = S 4 , at this time, the adjustment ratio of the effective gas outlet of the combustion chamber to the effective inlet flow area of the supplementary combustion chamber is 1:4, and the engine is in a high-flow working state.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com