Adaptive local activation transpiration cooled hypersonic speed leading edge thermal-protection method

A technology of sweating cooling and hypersonic speed, applied in the direction of heat reduction structure, aircraft parts, fuselage, etc., can solve the problem of low cooling efficiency, achieve the effect of improving thermal protection effect and optimizing utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0017] The preferred specific implementation of the hypersonic leading edge thermal protection method for self-adaptive local activation of sweat cooling of the present invention is:

[0018] include:

[0019] A leading edge body with a microporous structure is prepared by using a high temperature resistant material, and a layer of sublimation impermeable ablation coating is covered on the surface of the leading edge body;

[0020] A coolant supply channel is fixedly connected to the rear of the leading edge body, and the coolant is pre-sealed in the cooling cavity surrounded by the leading edge body;

[0021] When the surface temperature of the ablative coating is below the sublimation temperature of the material of the ablative coating, the pores of the surface are closed and the sweat cooling system is not activated;

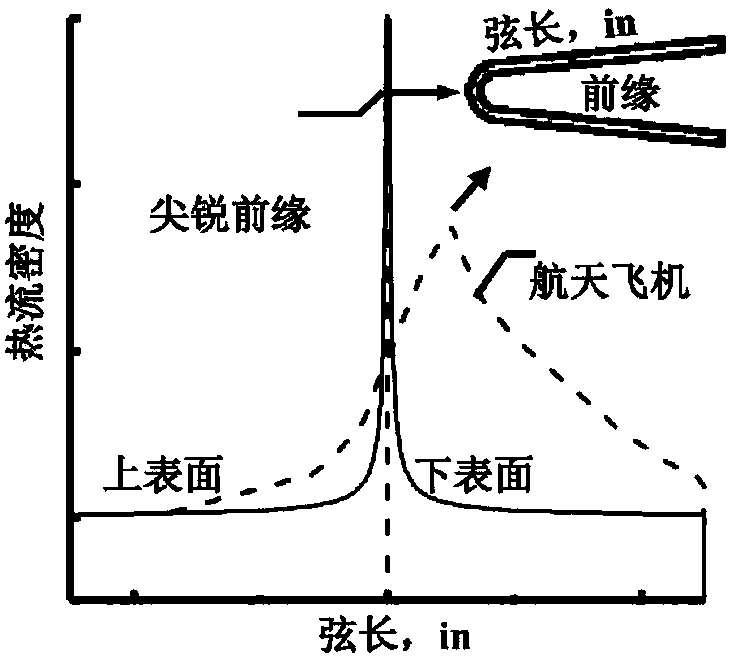

[0022] Under the action of external changing heat flow, the ablative coating located at the stagnation point of the leading edge body with high heat flow is...

specific Embodiment

[0036] Such as figure 2 , image 3 As shown, the present invention includes a leading edge body 1 with a microporous structure prepared from a high temperature resistant material. The surface of the porous leading edge is covered with a layer of sublimation-type impermeable ablation coating 2. Behind the leading edge body 1 The part is connected with the coolant supply passage 3, and the coolant is sealed in the cooling cavity 4 in advance. Such as figure 2 As shown, when the surface temperature of the coating 2 is lower than the sublimation temperature of the ablation material, the pores on the surface of the porous front 1 are closed, and the active sweating cooling system is not activated at this time; image 3 As shown, under the action of externally changing heat flow, the ablative coating 2 located in the local high heat flow region of the stagnation point of the leading edge is sublimated preferentially, the active sweating cooling mechanism is locally activated, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com